Electronique Telematique ETELM Canada BSTETRA460 Tetra Base Station User Manual netis B maintenance guide V1 1

Electronique Telematique ETELM Canada Inc Tetra Base Station netis B maintenance guide V1 1

Contents

netis B maintenance guide V1.1.part1

NeTIS MAINTENANCE GUIDE – Version 1.1 1/139

Version

Date Modifications Sign.

1.0 20/05/11 CREATION LM/PM

1.1 25/04/13 Add 2.6.7 PM/LM

N

Ne

eT

TI

IS

S

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

A

AS

SS

SI

IS

ST

TA

AN

NC

CE

E

G

GU

UI

ID

DE

E

ETELM

9, avenue des Deux Lacs

P.A de Villejust

91971 Courtaboeuf – cedex

Tel : +33.1.69.31.22.84

Fax : +33.1.69.31.22.61

Web site : www.etelm.fr

RC : Evry 320 565 443

NeTIS MAINTENANCE GUIDE – Version 1.1 2/139

1.

PRESENTATION OF A STANDARD TETRA NETWORK ................................................................. 5

2.

NETIS -B ...................................................................................................................................................... 6

2.1

P

RESENTATION OF THE BASE STATION

....................................................................................................... 6

2.2

D

IFFERENT VERSIONS

................................................................................................................................ 8

2.2.1

NeTIS Box version ........................................................................................................................... 8

2.2.2

Rackable versions ............................................................................................................................ 9

2.3

R

EAR FACE

.............................................................................................................................................. 11

2.3.1

NeTIS-B25 ..................................................................................................................................... 11

2.3.2

NeTIS –B25C ................................................................................................................................. 11

2.3.3

NeTIS-B25D .................................................................................................................................. 11

2.4

N

ORMAL

N

E

TIS-B

OPERATION

............................................................................................................... 12

2.5

H

ANDLING

............................................................................................................................................... 17

2.5.1

Plug-in modules ............................................................................................................................ 17

2.5.2

Rear face ....................................................................................................................................... 17

2.6

D

IAGNOSIS

/

M

AINTENANCE

.................................................................................................................... 17

2.6.1

General power faults ..................................................................................................................... 18

2.6.2

Power fault on a module ............................................................................................................... 19

2.6.3

Switch interface fault ..................................................................................................................... 19

2.6.4

Clock fault ..................................................................................................................................... 19

2.6.5

Transmission fault ......................................................................................................................... 22

2.6.6

Correct transmission ..................................................................................................................... 25

2.6.7

Conflicts between NMT alarms and LED of BS ............................................................................ 26

3.

NETIS-N ..................................................................................................................................................... 27

3.1

P

RESENTATION OF THE SWITCH

............................................................................................................... 27

3.1.1

Number of COM 3 or 4 boards ..................................................................................................... 27

3.1.2

Number of CODEC board (CCT) .................................................................................................. 28

3.1.3

Number of COMS boards .............................................................................................................. 28

3.2

L

AUNCHING

............................................................................................................................................. 30

3.3

N

ORMAL OPERATIONS

............................................................................................................................. 31

3.4

R

EMOVING SUBSETS

................................................................................................................................ 32

3.4.1

Plug-in modules ............................................................................................................................ 32

3.4.2

Rear face ....................................................................................................................................... 32

3.4.3

Ventilators ..................................................................................................................................... 32

3.5

D

IAGNOSIS AND MAINTENANCE

............................................................................................................... 32

3.5.1

General power fault ...................................................................................................................... 33

3.5.2

Power fault on module .................................................................................................................. 33

3.5.3

Clock fault ..................................................................................................................................... 34

4.

NETWORK FAILURE SCENARIOS ..................................................................................................... 36

4.1

N

ONE OF THE NETWORK EQUIPMENT IS OPERATIONAL

............................................................................ 36

4.2

T

HE NETWORK MANAGEMENT TERMINAL

(N

E

TIS-M)

IS THE ONLY OPERATIONAL EQUIPMENT ON THE

NETWORK

.......................................................................................................................................................... 37

4.3

N

O EQUIPMENT ON THE NETWORK IS OPERATIONAL EXCEPT FOR THE NETWORK MANAGEMENT TERMINAL

(N

E

TIS-M)

WHICH INDICATES THAT SWITCH IS OPERATIONAL AND ALL THE

BS

S OUT OF ORDER

..................... 37

4.4

BS

S ANSWER CORRECTLY ON THE

NMT,

BUT MOBILES DO NOT REGISTER ONTO THE NETWORK

. ............ 40

4.5

M

OBILES REGISTER CORRECTLY TO THE NETWORK BUT ARE UNABLE TO COMMUNICATE

....................... 42

4.5.1

There is no operational phoning between the terminals ............................................................... 43

4.5.2

No communications between terminals ......................................................................................... 44

4.6

T

HERE IS NORMAL TRAFFIC BETWEEN MOBILES BUT NOT WITH THEIR DISPATCHING

(

OPERATOR STATIONS

)

45

4.6.1

No phones between Dispatching and the terminals....................................................................... 45

4.6.2

No more signalling between Dispatching and the terminals ......................................................... 46

4.7

PABX

LINK PROBLEM

............................................................................................................................. 47

NeTIS MAINTENANCE GUIDE – Version 1.1 3/139

4.7.1

Signalling and phone out of order ................................................................................................. 47

4.7.2

Phone out of order ........................................................................................................................ 48

5.

NETIS-B & NETIS-N SOFTWARE ........................................................................................................ 50

5.1

N

E

TIS-B ................................................................................................................................................. 50

5.1.1

General .......................................................................................................................................... 50

5.1.2

Launching the « Niveau 2.exe » application ................................................................................. 50

5.1.3

NeTIS-B IP configuration .............................................................................................................. 52

5.2

N

E

TIS-N ................................................................................................................................................. 53

5.2.1

General .......................................................................................................................................... 53

5.2.2

Launching the NeTIS –N application ............................................................................................ 53

5.2.3

NeTIS-N IP configuration ............................................................................................................. 56

6.

PUTTY (REMOTE CONNECTION) ...................................................................................................... 58

7.

WINSCP – SOFTWARE UPDATE ......................................................................................................... 61

8.

NETWORKS ............................................................................................................................................. 68

8.1

« S

TARS

»

NETWORK

............................................................................................................................... 68

8.1.1

Settings .......................................................................................................................................... 69

8.2

« R

ING

»

NETWORK

................................................................................................................................. 71

8.2.1

Operating principles ..................................................................................................................... 72

8.2.2

Fault analyses and diagnosis ........................................................................................................ 73

8.3

E

THERNET LINK

(IP) ................................................................................................................................ 84

8.3.1

General presentation ..................................................................................................................... 84

8.3.2

Communications between appliances ........................................................................................... 86

8.3.3

Customers ...................................................................................................................................... 88

8.3.4

Network setting .............................................................................................................................. 89

8.3.5

Declaration of the NeTIS-B addresses on the tetra cs side ........................................................... 94

8.3.6

Switch signalling and phone port .................................................................................................. 96

8.3.7

Secondary network management terminal .................................................................................... 96

8.4

M

ULTI

-

SITE AND MULTI NETWORK MANAGEMENT TERMINAL

............................................................... 100

8.4.1

Presentation ................................................................................................................................ 100

8.4.2

Network setting ............................................................................................................................ 101

9.

CPUBDT SOFTWARE AUTHENTICATION (LEVEL 2) ................................................................. 106

9.1

T

HE AUTHENTICATION NETWORK MANAGEMENT TERMINAL

................................................................. 106

9.2

U

SE

........................................................................................................................................................ 107

9.3

I

NTEGRATION

........................................................................................................................................ 108

9.3.1

Equipment ................................................................................................................................... 108

9.3.2

Software ...................................................................................................................................... 108

9.4

P

RESENTATION

...................................................................................................................................... 109

9.4.1

Why authenticated? ..................................................................................................................... 109

9.4.2

What is authenticated? ................................................................................................................ 109

9.4.3

When to authenticate? ................................................................................................................. 109

9.4.4

New equipment ............................................................................................................................ 109

9.4.5

Validity period ............................................................................................................................. 109

9.4.6

Upgrade ...................................................................................................................................... 109

9.5

H

OW TO AUTHENTICATE

? ...................................................................................................................... 110

9.5.1

Authentication by phone .............................................................................................................. 110

9.5.2

Internet authentication ................................................................................................................ 110

9.6

H

ANDLING

............................................................................................................................................. 111

9.6.1

General ........................................................................................................................................ 111

9.7

M

ANUAL AUTHENTICATION

(

BY PHONE

) ............................................................................................... 112

9.7.2

Serial equipment connection ....................................................................................................... 117

9.8

A

UTOMATIC AUTHENTICATION

(

VIA

I

NTERNET

) .................................................................................... 118

9.8.1

Network connection to the equipment ......................................................................................... 118

9.8.2

Multiple authentications (IP network) ........................................................................................ 118

9.8.3

Serial equipment connection ....................................................................................................... 121

9.8.4

No connection to the equipment .................................................................................................. 123

NeTIS MAINTENANCE GUIDE – Version 1.1 4/139

9.8.5

Diagnosing an authentication problem on a NeTIS-B ................................................................ 123

10.

PABX GATEWAY .................................................................................................................................. 125

10.1

I

NTRODUCTION

................................................................................................................................. 125

10.2

E

QUIPMENT

....................................................................................................................................... 127

10.3

L

ED SIGNIFICATION

........................................................................................................................... 127

10.4

C

ONFIGURATION

............................................................................................................................... 128

10.4.1

Configuration to the IP PABX Gateway ................................................................................. 128

10.4.2

Configuration of the service network management terminal .................................................. 128

11.

MODULE DESCRIPTION .................................................................................................................... 129

11.1

P

OWER SUPPLY BOARD

: .................................................................................................................... 129

11.2

CPU-BDT

BOARD

............................................................................................................................ 130

11.3

CCT2

BOARD

.................................................................................................................................... 131

11.4

COM

BOARD

.................................................................................................................................... 132

11.5

COM3

BOARD

.................................................................................................................................. 133

11.6

DCTR

BOARD

................................................................................................................................... 134

11.7

SUPIP

BOARD

................................................................................................................................... 135

11.8

UCM

BOARD

.................................................................................................................................... 136

11.9

UCM2

BOARD

.................................................................................................................................. 137

11.10

P

OWER AMPLIFIER

(PA) .................................................................................................................... 138

NeTIS MAINTENANCE GUIDE – Version 1.1 5/139

1. PRESENTATION OF A STANDARD TETRA

NETWORK

System composition

A system is composed of:

One or more NeTIS-Ns and one or more sites, each one composed of one or more base

BS stations (NeTIS-B).

Of a main NeTIS-M service network management terminal and eventually one or

more secondary NeTIS-M service network management terminal

Standard operator stations supplied by ETELM or supplied by other enterprises which

form Dispatching

Portable and mobile terminals

SO, T2 links

Specific applications: for example data transmission.

NeTIS MAINTENANCE GUIDE – Version 1.1 6/139

2. NETIS -B

2.1 Presentation of the base station

NeTIS-B is a duplex TETRA transmitter receiver connected to the switch using an IP or G703

or V11 link or it can operate autonomously (TETRAG).

It manages a TETRA carrier which includes a signal channel and three phone channels.

The base station is composed of the following sub-sets:

A ventilation unit

An electronic unit with a backplane that can receive the following plug-in modules:

Power supply (ALIM)

CPU (CPUBDT)

Demodulator/ Down converter (DCTR) 2 slots for the use of 1 or 2 channel

diversities.

Modulator/Up converter (UCM2)

Power amplifier (PA)

The synthetic view below is an example of 4 site architecture.

NeTIS MAINTENANCE GUIDE – Version 1.1 7/139

64Kb/s

64Kb/s

BS

2Mb/s

2Mb/s

BS

BS

2Mb/s

V24

SW

SW

BS

T2

IP

T2

PSTN

PABX

Dispatchings

SW

SW

SW

SW

ISI

ISI

ISI

console d'administration

NeTIS MAINTENANCE GUIDE – Version 1.1 8/139

2.2 Different versions

2.2.1 N

E

TIS

B

OX VERSION

2 handled box

NeTIS-B25 base

station

Locations for accessories

(duplexer, hub …)

NeTIS MAINTENANCE GUIDE – Version 1.1 9/139

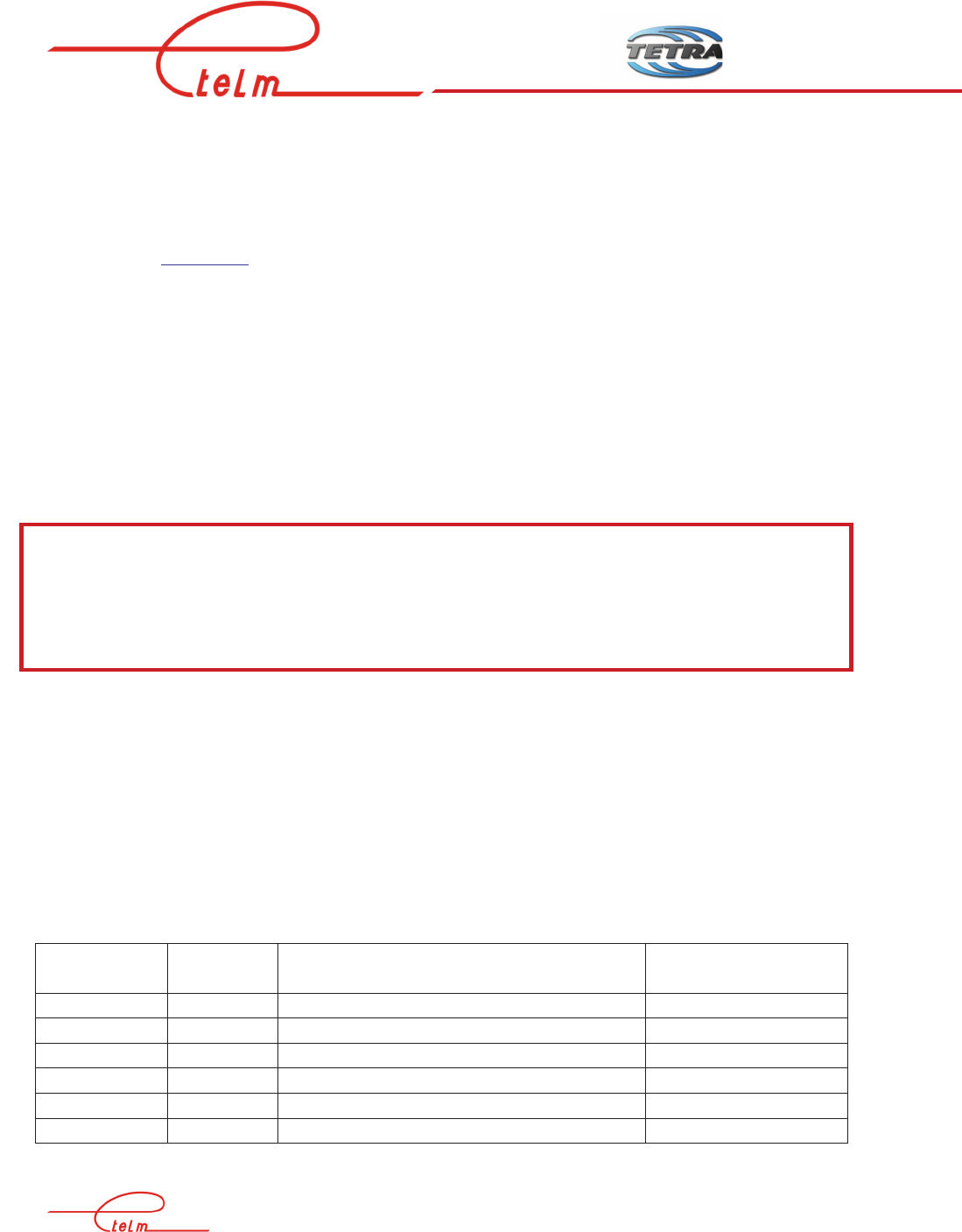

2.2.1.1 NeTIS-Box front view

2.2.2 R

ACKABLE VERSIONS

2.2.2.1 NeTIS B-25

NeTIS MAINTENANCE GUIDE – Version 1.1 10/139

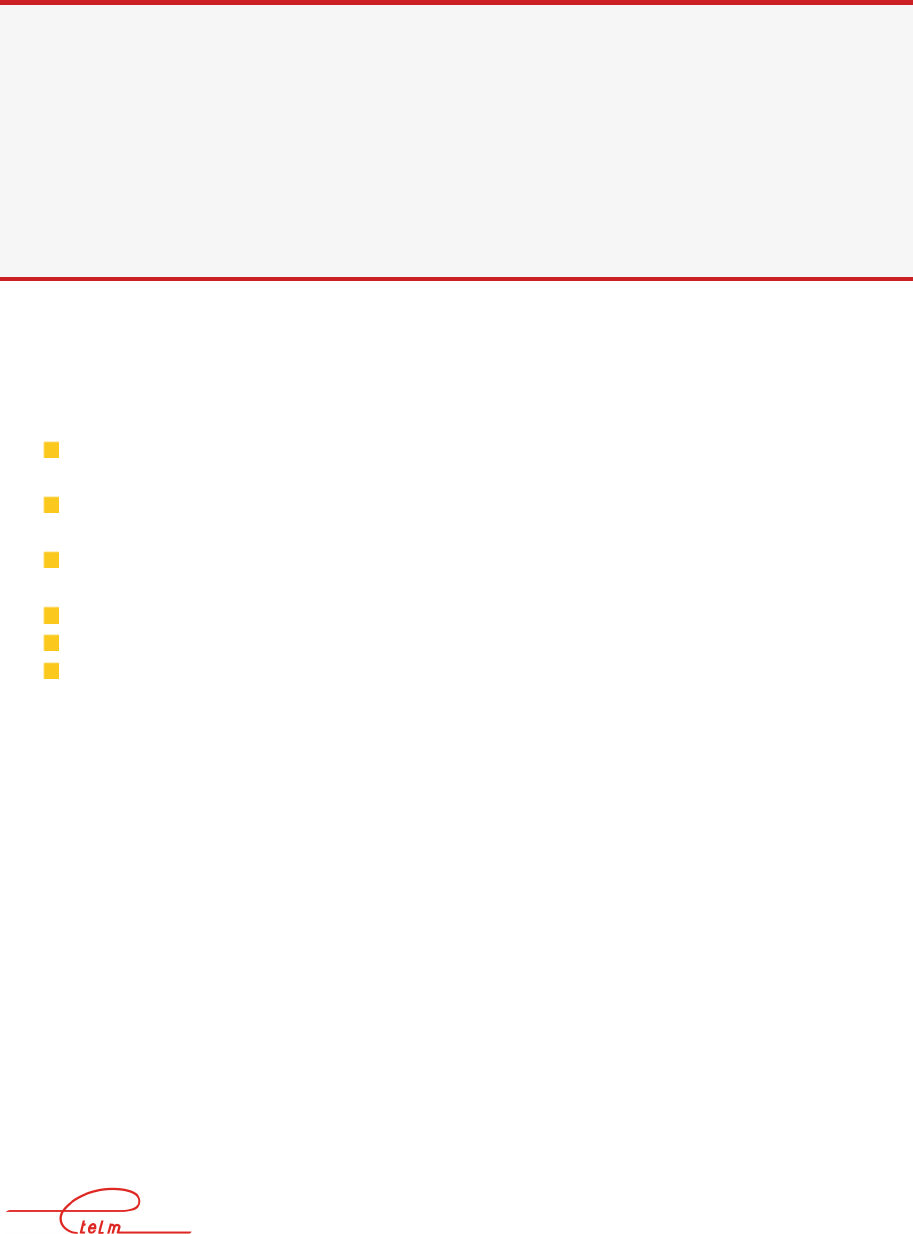

2.2.2.2 NeTIS B25-C

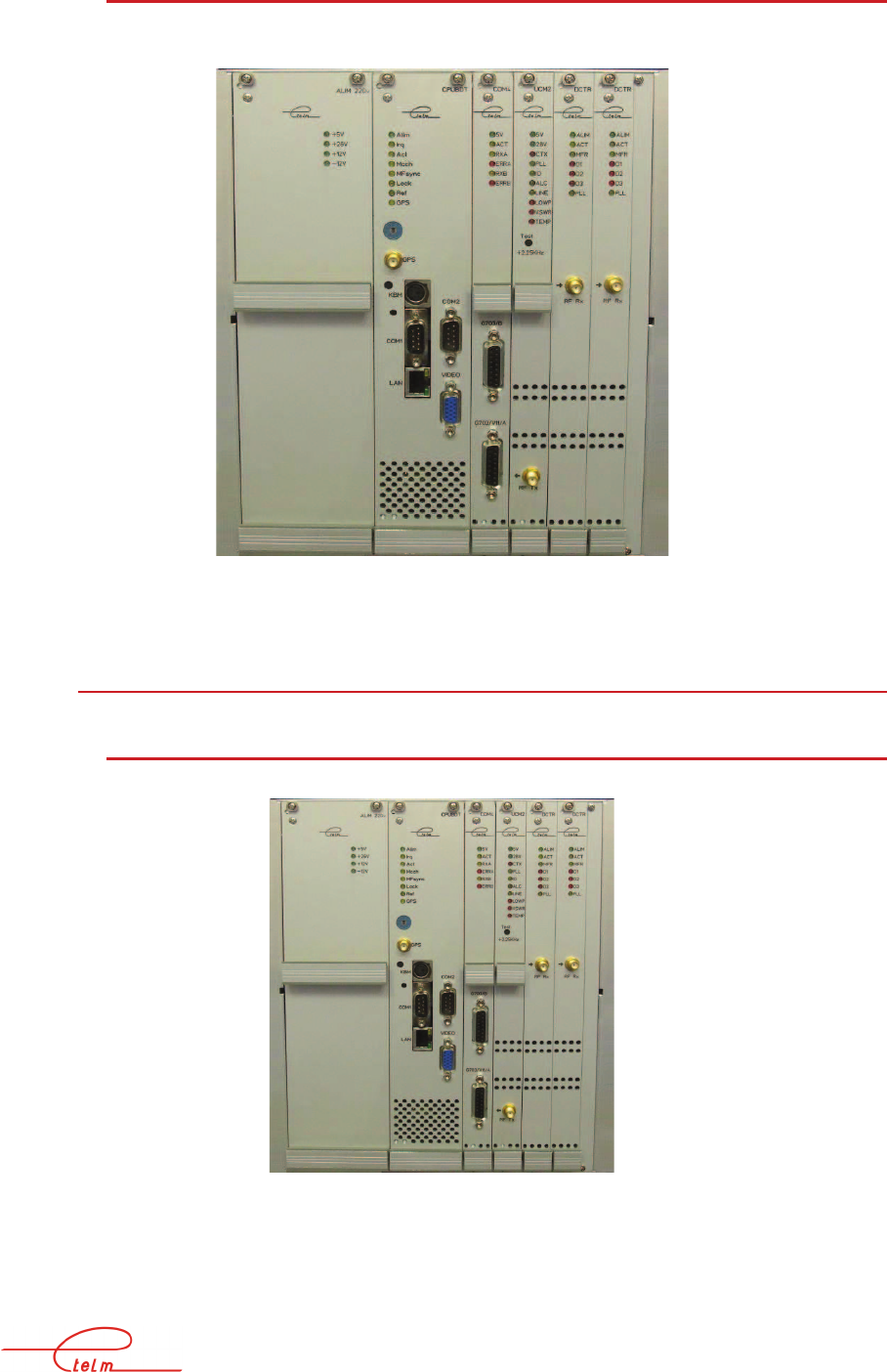

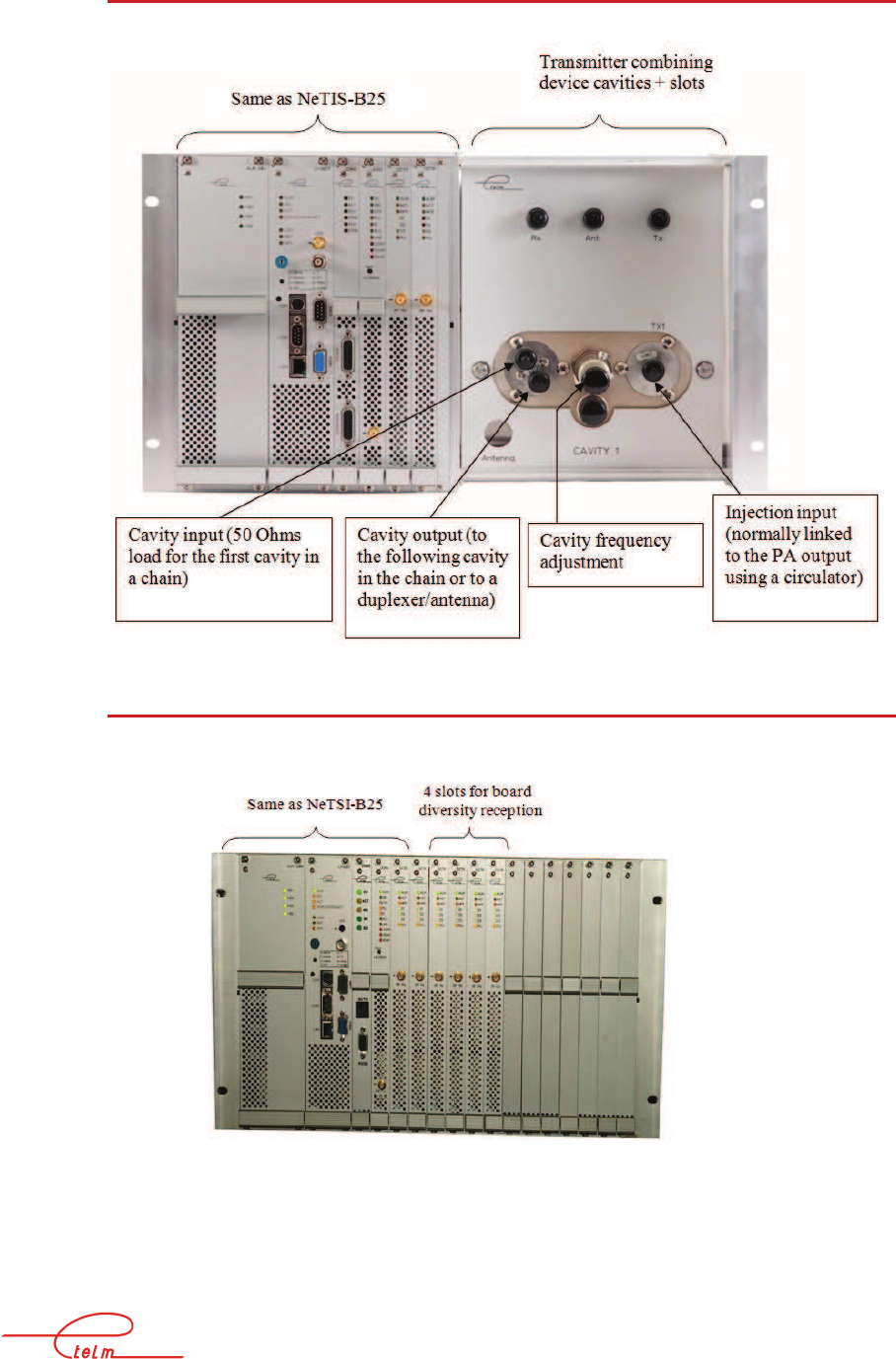

2.2.2.3 NeTIS-B25-D

NeTIS MAINTENANCE GUIDE – Version 1.1 11/139

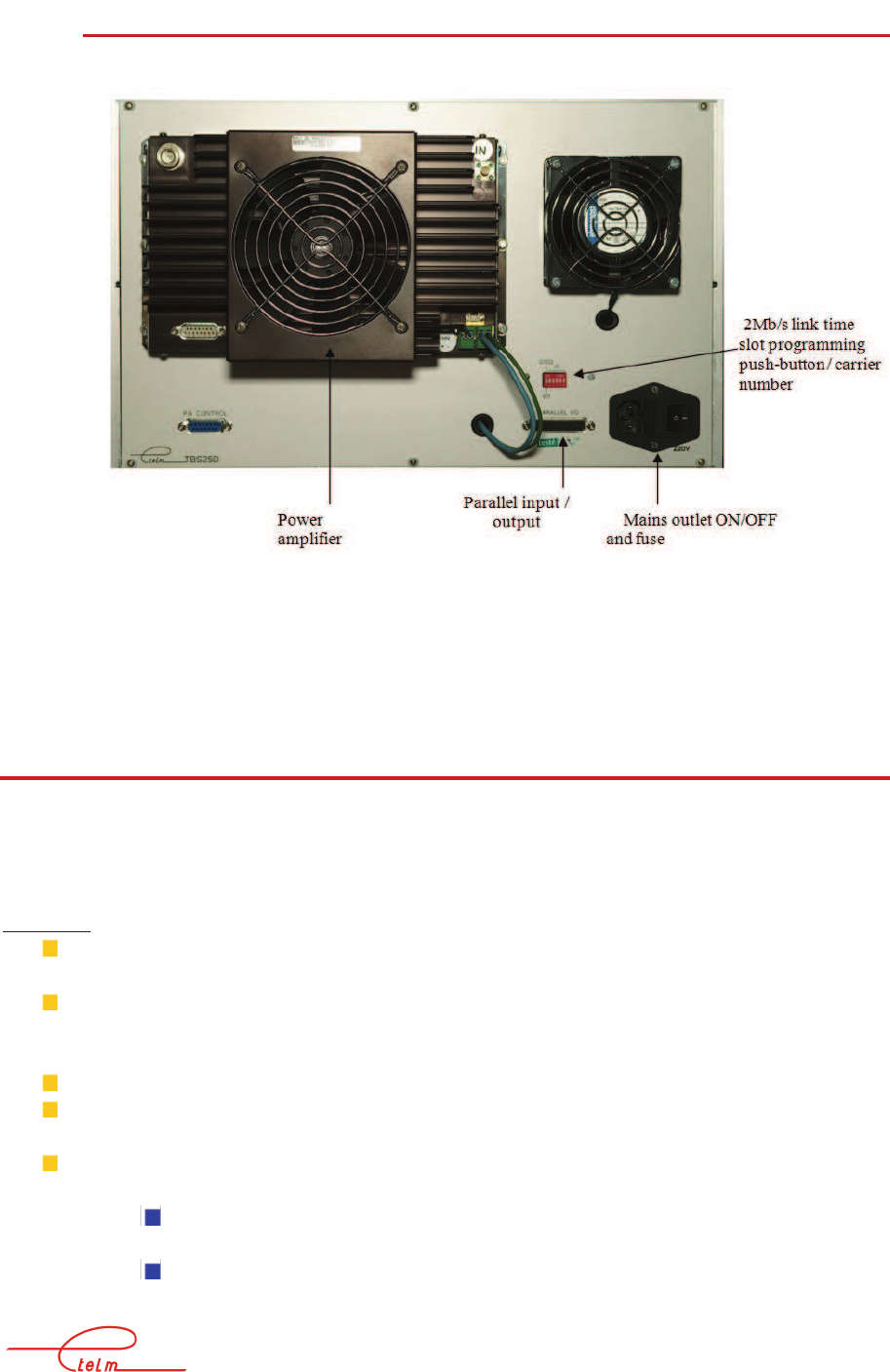

2.3 Rear face

2.3.1 N

E

TIS-B25

2.3.2 N

E

TIS

–B25C

NeTIS MAINTENANCE GUIDE – Version 1.1 12/139

2.3.3 N

E

TIS-B25D

2.4 Normal NeTIS-B operation

When powered on, the NeTIS normal behaviour is the following: Two phases should be

observed.

1

st

phase:

All the power indicators light (all the power supply module indicators and the

different power supply indicators on each other module)

The CPUBDT board operates immediately and supplies all the clock signals the

system needs; the 8 test signals (8Khz; 64 KHz; HT; ...) that are selectable using the

(blue) switch are available on the BNC connector of the BDT module.

The INT indicator for the module flashes

The module loads its software and then runs it in several phases

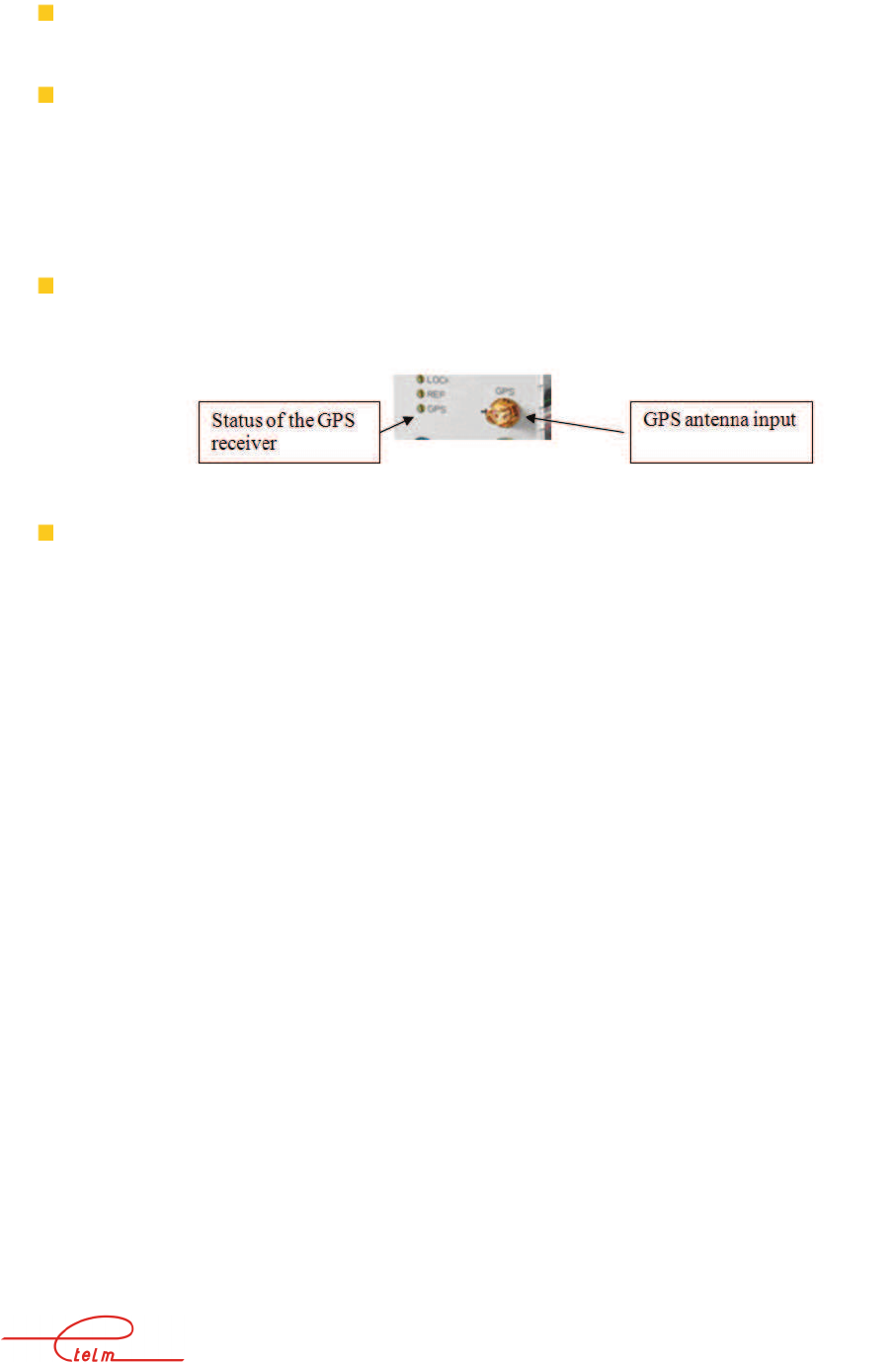

If the CPUBDT is fitted with the GPS synchro module, the operation of this board is

as follows:

The indicator flashes very slowly when the GPS module is present but

reception is bad

The flashing is per second when the GPS module is present and reception is

correct.

NeTIS MAINTENANCE GUIDE – Version 1.1 13/139

The transmission command, lower power and TOS indicators for the UCM board are

off. Only the ALC indicator flashes

Verification of the state of the different modules and files - if a problem is detected the

remaining operations may be halted.

2

nd

phase:

The CPUBDT board operates immediately and supplies all the clock signals the

system needs; the 8 test signals (8 KHz; 64 KHz; HT; ...) that are selectable using the

(blue) switch are available on the BNC connector of the BDT module.

The INT indicator for the module flashes

The ACT indicator on the CPUBDT board starts flashing which means that the

programme is running

The EF/ indicator on the UCM board lights (the CPUBDT loads data into the module)

and then the ALC and COR indicators light alternately

The MCCH indicator on the CPUBDT board lights if the BS manages the MCCH

channel

The PLL and CTX indicators light and the ALC and COR indicators turn off => the

BS is transmitting

The programme itself runs

The base station can be in one of the three following situations:

The base station has a correct link with the switch: the switch then uploads

the base station configuration and the base station transmits.

The link with the switch is not established (or the switch is stopped) and the

base station is not programmed to switch to degraded mode: in this case the

base station remains on standby

The link with the switch is not established but the base station is

programmed to switch to degraded mode: in this case the base station

behaves as an automatic TRA-2M relay and transmits.

It is important to note that TETRA mobiles synchronise on the signal received from the

relay transmitter or the base station and that they immediately cease all transmissions if the

signal is not correct – it is therefore essential, when faced with a 'dumb' mobile, to start by

checking the station transmission before checking anything on the mobile itself.

NeTIS MAINTENANCE GUIDE – Version 1.1 14/139

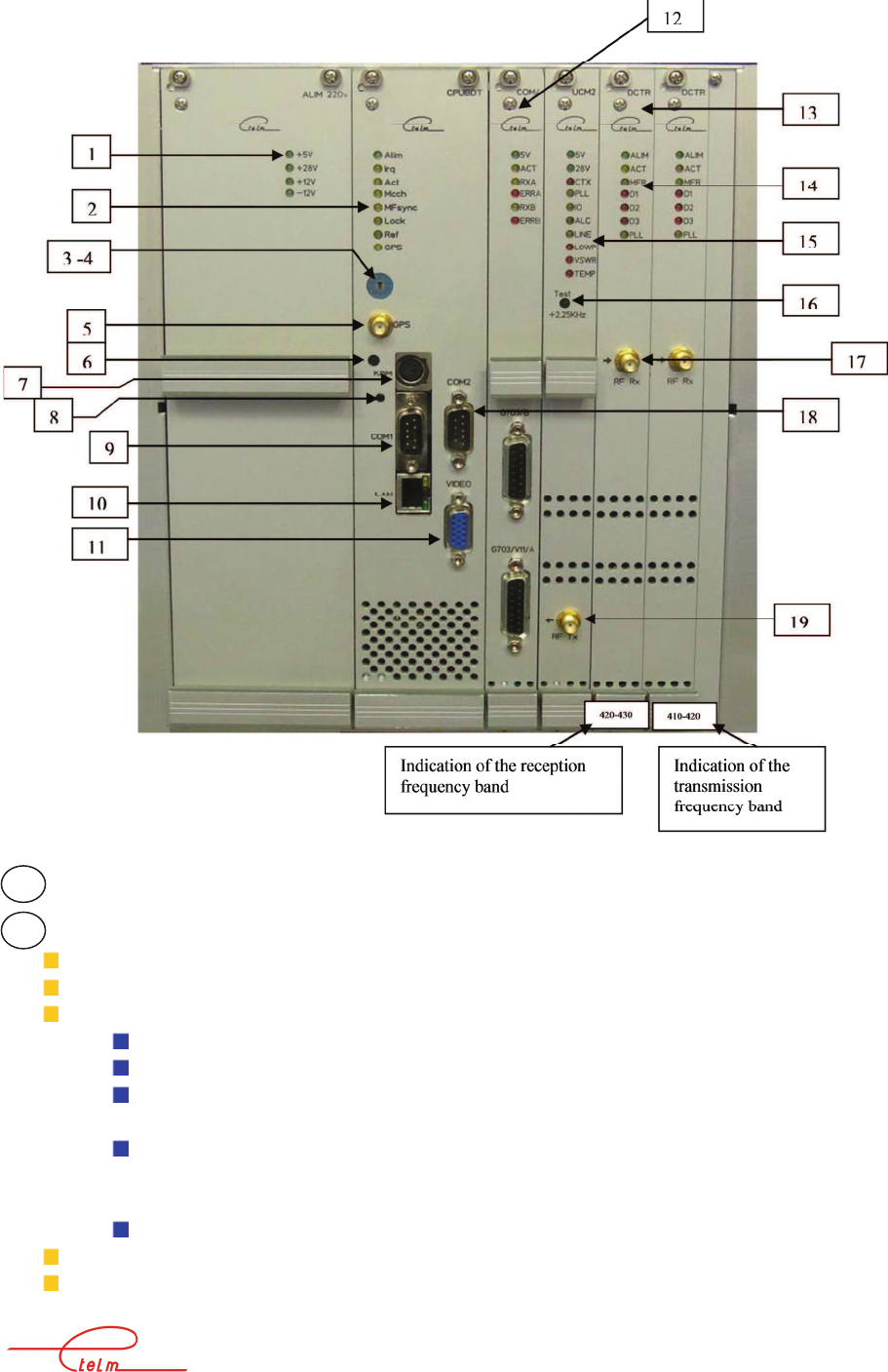

Power indicators - normally all on

CPUBdT board indicators

2a power supply normally on

2b 'IRQ’ normally fast flashing

2c 'ACT’ (Activity):

Static (on or off): the software is not operating correctly

Fast flashing: no reception board (DCTR) detected

Slow flashing (1 second): the base station has received a configuration from a

switch

Very slow flashing (2 seconds): the base station has received a configuration

from a switch but has switched to degraded mode (link with the switch has

been cut)

Very fast flashing: software fault (Authentication or other problem)

2d 'MCCH’ indicates that the base station is carrying the site MCCH

2f 'LOC’ on if the internal time base is in slave mode – to the GPS or the G703 link

or V11 link

1

2

NeTIS MAINTENANCE GUIDE – Version 1.1 15/139

2g 'REF’ Presence of a synchronisation by link (communications board)

2f 'GPS’ This indicator has different flashing frequencies,

State 1: On 100ms / Off 100 ms No GPS module or defective GPS module

State 2: On 100ms / Off 900 ms GPS module OK / Satellite acquisition in

progress

State 3: On 100ms / Off 5 s Module GPS OK / Antenna fault

State 4: On 1 s / Off 1 s GPS module OK / Satellites OK

State 5: On 2s / Off 2s GPS module OK / Satellites lost, synchronisation

maintained for 8 min 30 s before switching to the internal reference

The board's synchronisation source can be determined from the indicator states,

'LOC’ off whatever the state of the other indicators means synchronisation on the internal

reference

'LOC’ and 'REF’ on mean synchronisation on the link

'LOC’ on and 'REF’ off and 'GPS’ state4 or state5 means synchronisation on the GPS

The clock test connector is controlled by selector 4

Position 0: 8 KHz (used on G703)

Position 1: 64 KHz (used on G703)

Position 2: 10 MHz (internal reference clock)

Position 3: TETRA multiframe

Position 4: TETRA frame

Position 5: TETRA time slot

Position 6: 2,048 MHz (G703)

Position 7: TETRA symbols

Clock signal selector on test connector 3

GPS antenna connector

Opening for access to the clock frequency internal reference fine tuning potentiometer

for the base station

Keyboard and mouse connector (diagnosis mode only)

Reset push button - this push button is accessible using a pointed object. Launching

this command triggers a restart of the software which is indicated by a tone on the

restart

COM1 serial connector

RJ45 connector for LAN network

Video connector for local screen connection (diagnosis mode only)

3

4

5

6

7

8

9

10

11

NeTIS MAINTENANCE GUIDE – Version 1.1 16/139

Location for board communications (option) or a COM4 board for network mode

connection to a switch using a V11 or G703 link, or a COM S board for connection to

a PABX in autonomous mode.

Location for an optional DCTR board for a second diversity reception channel.

DCTR operation indicators

14a ALIM Normally on

14b ACT Flashes once per second as soon as the software is running correctly

14c MFR Flashes at high speed (perceivable by the lessening of the

brightness of the indicator) if the board is operating correctly

14d D1 On when a high level radio signal is received

14e D2 On when a block of high power radio data is received (threshold

around -70dBm)

14f D3 Indication of the correct decoding of the TETRA block received

as input

14g PL Local oscillator slave mode indicator (normally on)

When reception frequency of the board is changing the indicator flashes

briefly.

UCM board operation indicators

15a ALIM Normally on permanently

15b 28V PA power supply: Normally on permanently

15c CTX Radio transmission indicator

15d PLL Transmission oscillator slave mode indicator: Normally on permanently

15e IO Reception of messages from the BS software indicator.

15f ALC Power slave mode operation indicator: normally permanently on

15g LINE PA linearization indicator

15h LOWPW Low power alarm: normally off

15i VSWR Too high reflected power alarm: normally off

15j TEMP PA temperature alarm: normally off

'11111' transmission command - this push button can be accessed using a sharp object.

When it is activated, the TETRA modulation signal is replaced by a series of 1 symbol

which correspond to a pure radio carrier offset from the nominal frequency by +2.25

KHz - this function is used to check the frequency of a base station using an analogue

radio bench.

Radio input - level between - 20 dBm and - 130 dBm

COM2 serial connector used to connect a local network management terminal

Radio output to the PA, nominal level - 5 dBm

12

13

14

15

16

17

18

19

NeTIS MAINTENANCE GUIDE – Version 1.1 17/139

2.5 Handling

2.5.1 P

LUG

-

IN MODULES

The different modules must be plugged in or removed when power is off.

Before removing a module, disconnect the eventual coaxial connections from its front face

To remove a module, first remove the screws from the four corners of the front face of the

module before gently extracting it by pulling it forward using the extraction handles.

The power supply module has an auxiliary connector (mains input) which must be

disconnected before completely extracting the block.

Plugging a block back in must be done gently but firmly; once the block is correctly engaged

on its connector, push hard on the set to place it correctly.

2.5.2 R

EAR FACE

Before any interventions inside the chassis, the mains or 48V input at the rear of the chassis

must be disconnected.

The rear face is removed by unscrewing the 4 screws at each corner of the rear face; the

connection cables are long enough to be able to lay the face on a flat, cleared surface.

2.5.2.1 Ventilators

Access to the ventilators differs depending on whether the NeTIS is the rack version or the

box version:

Rack version:

The mains power input located to the rear must be disconnected and then the rack mounting

screws must be removed in order to extract the entire block from the front.

Box version:

Access to the ventilators is from the bottom: remove the screws on the sides and then lift the

entire appliance; the lower part comes away.

2.6 Diagnosis / Maintenance

WARNING: placing a base station in test on a site can cause major radio disruptions both on

the network on which the station is working and on the other networks in the region

NeTIS MAINTENANCE GUIDE – Version 1.1 18/139

(frequency change) - it is therefore strongly recommended to disconnect the base station from

the antenna and to reconnect it to a load before any tests.

2.6.1 G

ENERAL POWER FAULTS

No indicators on

Check the general fuse located to the rear on the main power input block

Check that there is 220V

Check the position of the switch located on the rear face

If everything is correct:

Unplug the power supply module

Disconnect the auxiliary mains supply cable from the module

Check for 220V on this disconnected connector

If everything is correct: the power supply module is out of order

Otherwise the internal mains wiring or the switch or the mains filter are

defective

Only the 220v indicator is on, on the power supply module:

Unplug the power supply module

Power off and on again

If the indicators turn on again there is either a short circuit on a power supply, or all the

circuits were put on stand-by following a general power surge

One or mode indicators on the power supply module are off:

Turn off the TBS11

Wait for a few seconds

Turn the appliance back on

If the indicators are back on:

It indicates a power overload which caused the corresponding power supply

circuit to go into safety mode

Check consumption

If the fault persists,

Turn the appliance off and unplug all the modules using the defective voltage;

Turn the appliance back on

If the fault persists,

The power supply module is defective

If the fault disappears,

Plug the removed modules back in, one by one (turning power off each

time) to isolate the defective module

NeTIS MAINTENANCE GUIDE – Version 1.1 19/139

2.6.2 P

OWER FAULT ON A MODULE

The power supply indicator on the module stays off even though the 5 volt indicator is on the

power supply module:

Each module has a fuse soldered to the 5 volt input, close to the 96 point Europe connector. If

this fuse is broken, it is possible to replace it and closely watch when powering back on; if the

fuse breaks again, the module must be returned for repair.

Some modules also have fuses on other voltages; when these fuses break it is not shown by

the power supply indicator (which only indicates the presence of a +5 volt power supply).

2.6.3 S

WITCH INTERFACE FAULT

The defect can come from the CPUBDT board, or from the IP link itself.

WARNING: the fault diagnosis must be carried out taking into account the settings of the

degraded mode with the following cases:

A base station not programmed for degraded mode with an interface fault ceases all

radio transmission

A base station programmed for degraded mode continues to transmit (as a TRA-2M) if

there is an interface fault - the MCCH indicator is necessarily on (but the fact that it is

on does not necessarily indicate a fault)

The link between the switch and the BS is managed by the CPU board; this board should

always show:

The 5 volts indicator on

The yellow "ACT" indicator flashing slowly

The red "INT" indicator flashing quickly

The yellow "MCCH" indicator on if the BS is carrying the MCCH

Refer to the authentication chapter in the event of an intervention of the CPUBDT in the

following cases:

Compact flash replacement

CPUBDT replacement

LEVEL2 software upgrade

When the link is correctly established the base station must synchronise on the link - i.e. the

'synchro signal present' and 'lock' indicators on the module should be on.

2.6.4 C

LOCK FAULT

A high number of defects can have their origin in a clock fault; they should therefore be

checked systematically before any research on the other signals.

NeTIS MAINTENANCE GUIDE – Version 1.1 20/139

*Check according to your measurement bench:

With a digital TETRA bench measure the frequency error at the UCM or PA output; it

should be less than +-100Hz. If this is not the case, check the clocks.

With an analogue bench, check the frequency error at the UCM or PA output; it

should be less than +-100Hz. To do this keep the 2.25 KHz test button on the face of

the UCM pressed down in order to observe a pure offset carrier compared to the TX

BS frequency of 2.25 KHz.

If this is not the case, check the clocks:

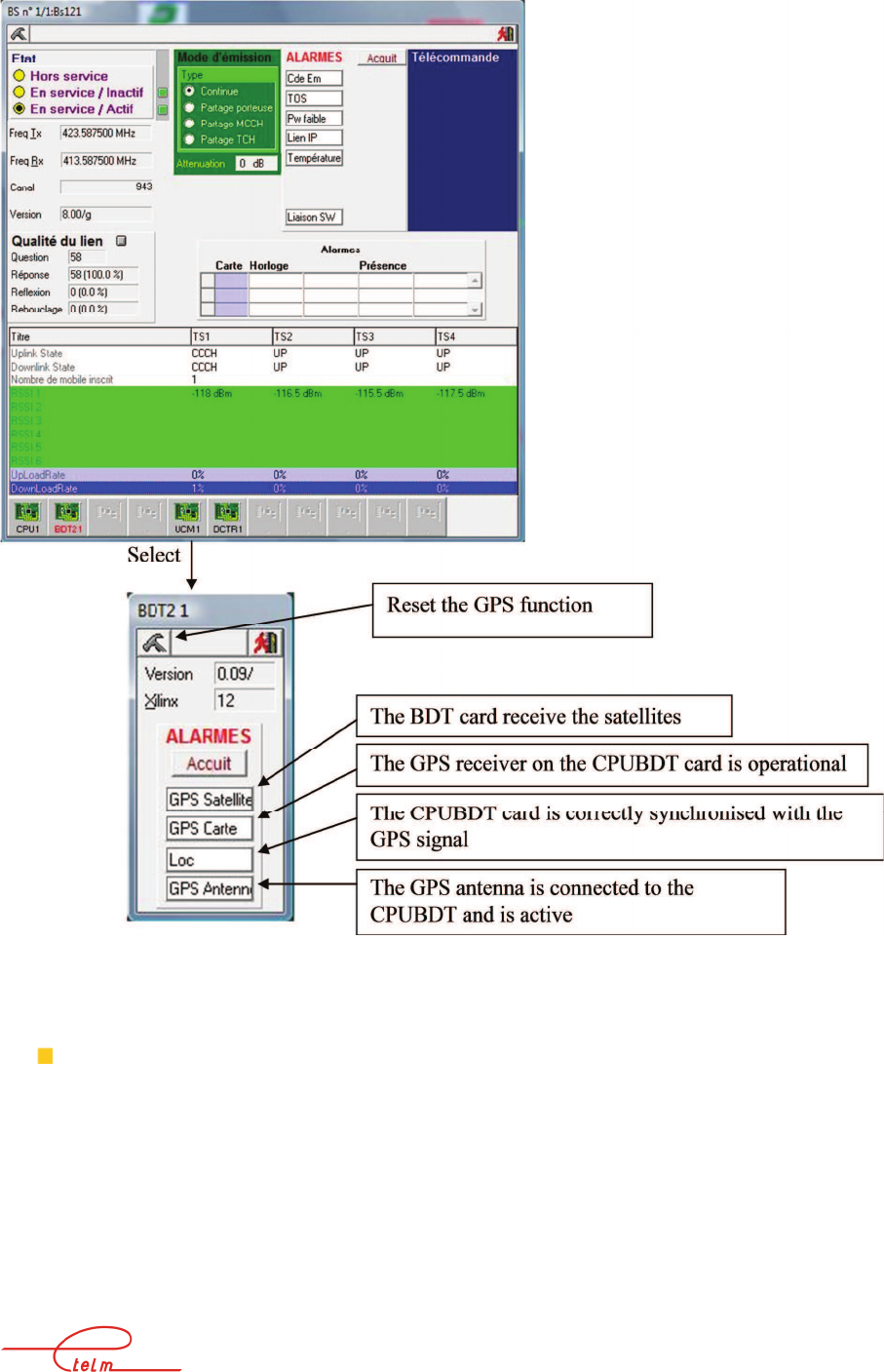

If the BS is synchronised on the GPS signal, then check the rhythm of the GPS

indicator on the CPUBDT board

Or consult the GPS alarms on the network management terminal by zooming on the

NeTIS and then viewing the BDT status by clicking on the resource (See below)

NeTIS MAINTENANCE GUIDE – Version 1.1 21/139

If the BS is synchronised on its own LO (local oscillator), then adjust the CPUBDT

LO using the potentiometer on the face (small hole)

NeTIS MAINTENANCE GUIDE – Version 1.1 22/139

If the BS is synchronised with a G703 link, then:

Adjust the remote SWITCH reference if the CPUBDT is not synchronised

with an external clock source

If the SWITCH is synchronised with the GPS, the CPUBDT receives the GPS signal;

check the rhythm of the GPS indicator on the CPUBDT

The general check of the clock signals is carried out from the front face of the CPU_BDT

module using the selector located on the top.

All the clock signals must be perfectly recurrent, stable and exempt from jitter.

Check in the following order:

position 7: TETRA clock symbol 18 KHz

position 5: clock time slot 70 Hz

position 4: clock frame 70 / 4 Hz = 17.5

position 3: multiframe 1.02 second (18 frames)

2.6.5 T

RANSMISSION FAULT

2.6.5.1 The transmission command indicator, CTX on the UCM stays off

Check that the UCM is receiving data from the central processing unit - this traffic is viewed

via the IO indicator on the UCM front face which should light.

If data is being received, the UCM board is defective.

Otherwise check the central processing unit and the settings.

NeTIS MAINTENANCE GUIDE – Version 1.1 23/139

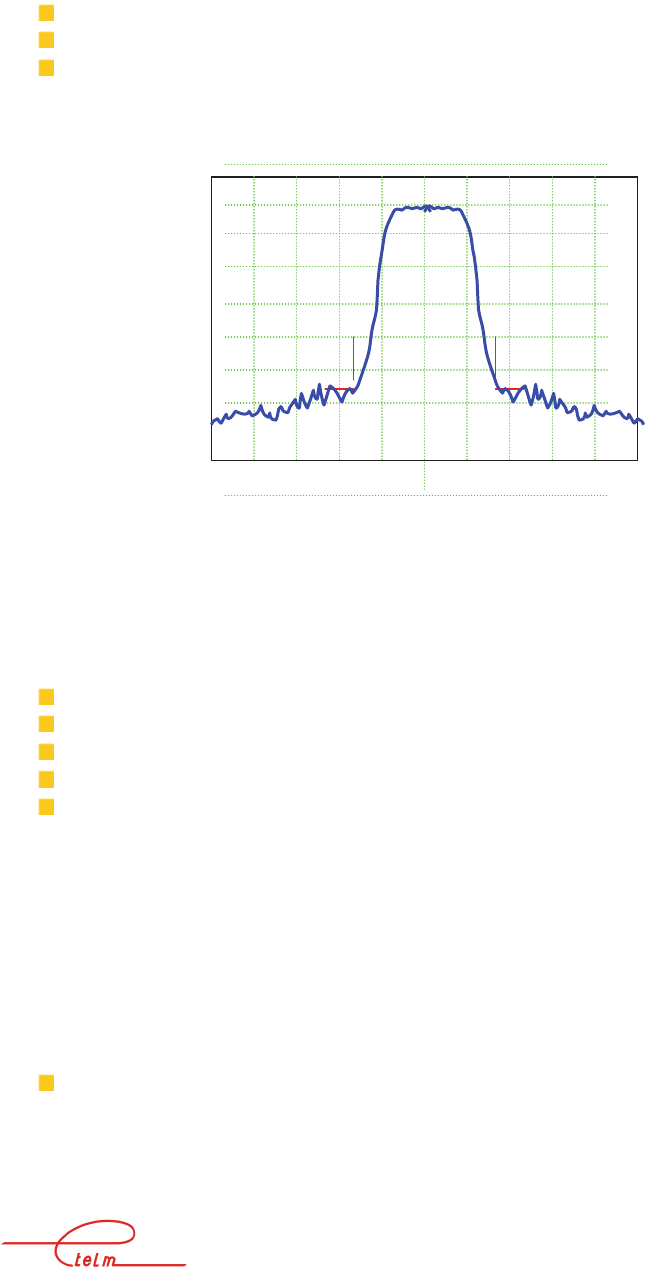

The transmission command indicator, CTX on the UCM is on

Measure the RF signal output from the UCM board

On a spectrum analyser the signal should have the following form:

Central frequency Fo MHz / 10 KHz / division Fo: programmed radio frequency

1 KHz bandwidth

10dB/division

If the spectrum only shows rays or if the spectrum overshoots the 25 KHz width, the UCM

board is defective

When a TETRA radio bench is available, the RF MHz signal will be analysed by the bench

programmed on the RF frequency of your BS. The bench is configured as follows:

Base station test

Duplex test, Tx test

RF MHz carrier

Synchronisation acquisition on 'normal and synchro burst'

Constellation measurement

If the bench does not synchronise, check the spectrum as indicated previously.

If the bench synchronises, it indicates the signal power and its frequency error; it should be

less than +-100Hz. If this is not the case, check the clocks. (See §2.6.4)

The output level of the UCM board: around - 5 dBm.

Pay attention to the power regulation from a set point supplied by the PA (Power Amplifier)

which can vary this level. A check of the power of the PA output must also be carried out.

If no significant signal is present at this level, check that the UCM frequency band is

compatible with the desired value - if so the UCM module is defective.

NeTIS MAINTENANCE GUIDE – Version 1.1 24/139

If the signal is correct but has a carrier on another channel, check the transmission

channel programming and check the clocks; if these tests are correct, the UCM

module is defective.

If the signal is correct but on a carrier that is offset compared to the nominal value,

check the clocks or the synchronisation sources.

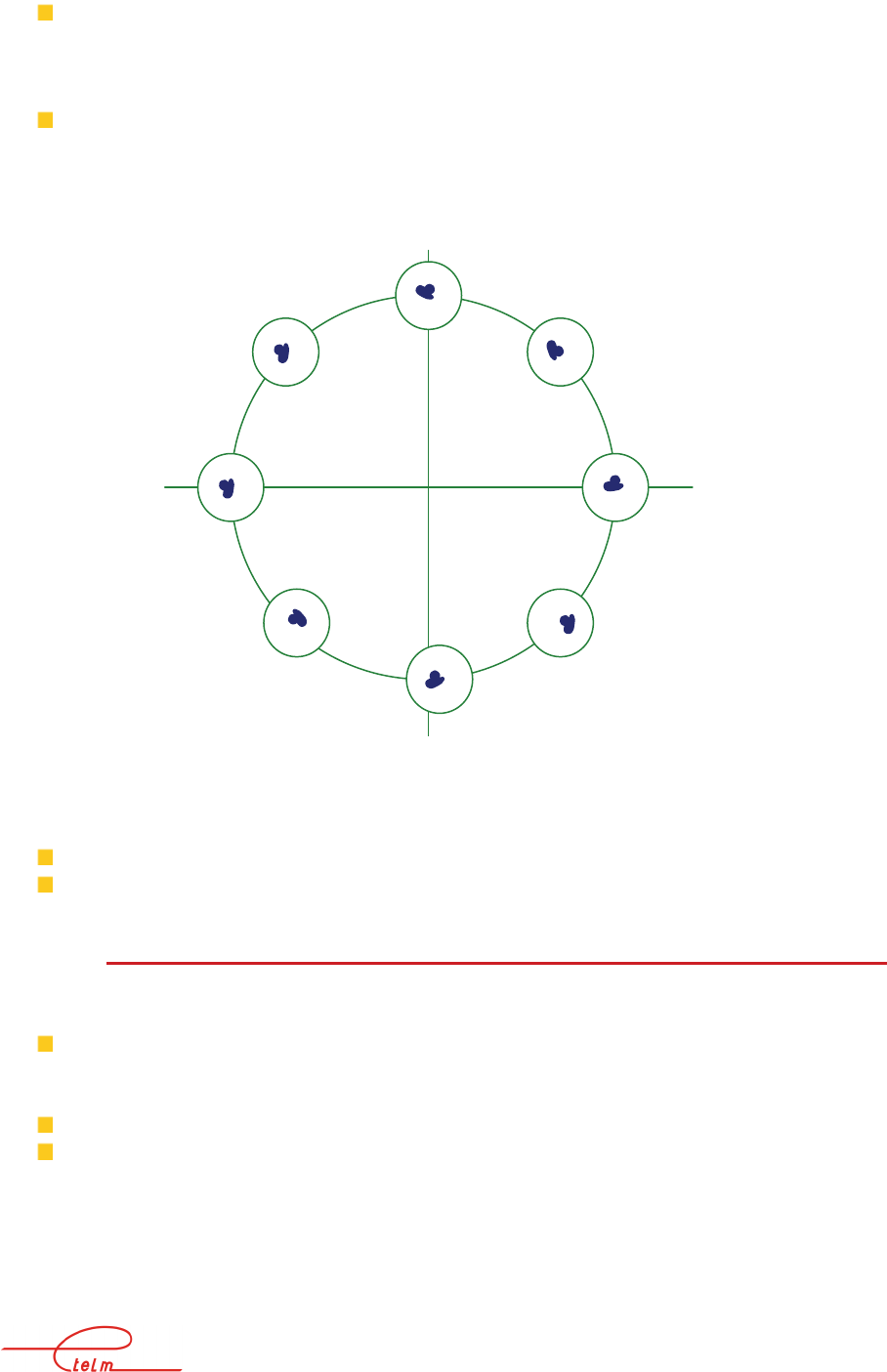

The complete constellation must comply with the diagram below:

If the constellation presents points that spread radially, check the level.

If the constellation presents points that spread at a tangent, check the clocks.

2.6.5.2 Possible alarms on the transmission chain

If the TOS indicator on the UCM board is on, disconnect the antenna and replace it with a 50

Ohms load.

If the TOS indicator switches off, check the antenna connections.

If the 'low power' indicator is on, disconnect the antenna and replace it with a 50 Ohms load.

If the indicator stays on the PA is defective (check its power supply)

If the indicator switches off there is probably an antenna connection problem which

caused a fault on the PA

If the 'low power' indicator is off, check the signal power output from the PA.

NeTIS MAINTENANCE GUIDE – Version 1.1 25/139

Also check the signal spectrum output from the PA; if the 'shoulders' lift, check the level at

the PA input; if this level is correct and the spectrum at this access has no lifting, the PA is

defective.

2.6.6 C

ORRECT TRANSMISSION

2.6.6.1 The mobiles do not attempt to register

Check the network and mobile settings, especially:

The compliance of the channel declared on both sides

The mandatory nature or not of the registration

The type of services provided by the BS or the system (phone, data)

The MCC and MNC network numbers

The mobile's authorisation on the system

2.6.6.2 The mobiles attempt to register

Place a reference mobile close to the BS receiver antenna on the site concerned in order that

the receiver (or receivers for the diversity option) receive a very strong field.

If the packet detection LED on the DCTR board briefly lights (each time a packet transmitted

by the mobile is received), the receiving chain is apparently correct and the fault is more

likely to be found before the BS or the site concerned; otherwise the receiver chain must be

checked.

Checking a receiver chain

Place a reference mobile close to the BS receiver antenna on the site concerned in order that

the receiver (or receivers for the diversity option) receive a very strong field.

If the packet detection LED on the DCTR board briefly lights (each time a packet transmitted

by the mobile is received), the receiving chain is apparently correct and the fault is more

likely to be found before the BS or the site concerned; otherwise the receiver chain must be

checked.

Preliminary checks

Connect the network management terminal in order to monitor the RSSI level (direct access

to this data can also be obtained using a screen and keyboard connected to the central

processing unit by launching the level measurement test (RSSI) by pressing the I key - this

function is terminated by pressing the key again - the field measurements scroll permanently

for each installed receiver channel). Make sure that this monitoring is correctly deactivated in

order to avoid disrupting the BS.

Disconnect the input to the antenna DCTR module (or to the duplexer). The indicated RSSI

level corresponds to the sound level at the input of the DCTR module; this level is normally

between -120 and -126 dBm

If the sound level increases too much when the RF input of the DCTR is reconnected,

the BS is probably correct and the pollution should be looked for upstream; it can

NeTIS MAINTENANCE GUIDE – Version 1.1 26/139

come from a disturbance or an incorrect adjustment of a duplexer or an incorrect

separation of the transmission and receiver antennas; to refine the diagnosis stop the

BS transmission by disconnecting the CPU from the PA.

Checking a DCTR circuit

Connect an RF generator to the DCTR input to be tested, adjusted to the programmed nominal

receiver frequency on the BS; the RSSI level indications should correspond within 3 dB to the

test generator level within the range of - 20 to - 90 dBm. Further, the D1 LED of the DCTR

module lights progressively as the generator level exceeds - 70 dBm. Several faults can be

detected at this level:

The viewed RSSI level is weak and almost constant whatever the generator level;

check the programmed receiver channel, check that the DCTR module is compatible

with the frequency band, find out if it is responding on a neighbouring carrier; check

the DCTR module

The viewed RSSI level varies correctly either at a weak level (- 90 to - 50 dBm), or at

a strong level (- 50 to - 20 dBm) but not over the entire range: the DCTR module is

defective

The viewed RSSI level varies correctly at a weak level but varies at levels greater than

- 40 dBm and the D1 LED does not light, the DCTR module is defective

The viewed RSSI level varies correctly at a strong level but not at a weak level

although the noise levels are correct: the DCTR module is probably defective, it

should be checked

2.6.7 C

ONFLICTS BETWEEN

NMT

ALARMS AND

LED

OF

BS

If there are different alarms on NMT for the same base station concerning VSWR, PA or Tx

and the LEDs on the base station do not correspond to this, that’s means that there is an issue

with the power alimentation of each board. In this case, the LED (+30v) on the supply board

is very weak or off.

1 – switch off the base station

2 – disconnect on the PA board (rear of the rack), supply cable (2 pins, green connector)

3 – disconnect the alarm connector (SubD 15pins)

4 – start the base station

If the LED +30v is ok, exchange the PA module

If the LED is still not working, exchange the main supply board

If both are not ok, check the different wire of supply

NeTIS MAINTENANCE GUIDE – Version 1.1 27/139

3. NeTIS-N

3.1 Presentation of the switch

Each switch has the following modules:

Power supply (ALIM)

CPU (CPUBDT)

IP phone sequencing board (SUPIP)

one or more communications boards (COM3 or 4) for the connection of the switch to

remote sites

one or more communications boards (COM3 or 4) for the connection of the switch to

the PABXs

one or more CCT boards (CODEC)

one or more COMS boards for S0 link management

3.1.1 N

UMBER OF

COM

3

OR

4

BOARDS

COM boards used for PABXs

One Com board for the same T2 access should support 30 simultaneous

communications

COM boards used for radio sites: the number depends on the style of network:

Ring network

Star network

IP network => no need for boards

NeTIS MAINTENANCE GUIDE – Version 1.1 28/139

3.1.2 N

UMBER OF

CODEC

BOARD

(CCT)

There should be as many CODECs as there are simultaneous phone communications exiting

the TETRA world.

One CCT board supports up to 16 CODECs.

The phone communications exiting the TETRA world are:

Mobile to telephone and telephone to mobile communications

Mobile group to telephone and telephone to mobile group communications

Dispatching to mobile and mobile to dispatching communications

Mobile group to dispatching and dispatching to mobile group communications

Mobile(s)/Mobile(s) communications listened to by dispatching

On the other hand, communications routed to another switch are not considered as exiting the

TETRA world (however they need a CODEC channel if they are to be listened to by a local

dispatching or if the telephone is a third party).

The photo on the following page gives the position of the different boards in the chassis and

the meaning of the indicators and their statuses during normal operation.

3.1.3 N

UMBER OF

COMS

BOARDS

The COMS board gives the possibility of having a S0 or T0 type phone connection.

This type of link carries 1 signal channel (D) and 2 phone channels 'B).

This board is therefore adapted to a small network wishing to limit resources dedicated to

phone communications (max. 2) and the cost of the access to the phone network.

The T0 or S0 access is processed in compliance with the VN4 and VN5 specifications of the

EURO-RNIS network

NeTIS MAINTENANCE GUIDE – Version 1.1 29/139

NeTIS MAINTENANCE GUIDE – Version 1.1 30/139

3.2 Launching

When powering on, the power supply indicators light and the time base board operates

immediately with the lighting of the following indicators:

TFB "synchronisation signal presence" if a synchronisation signal is configured and

present,

LOC indicating the internal reference oscillator is correctly locked.

The CPU board initialises and loads its resident flash disk software; this software is then

launched with:

1. The survey of available resources (COM and CCT boards).

2. The loading of the configuration for all the switch boards.

At this time the link with the network management terminal is established and the standby

screen for the network management terminal displays the representation of the link with the

switch in green.

The switch detects the presence of the base stations and uploads their configuration; each base

station successfully uploaded is declared available in the resources and the representation of

the link with them on the standby screen of the network management terminal changes to

green.

The traffic with the base station is established and it starts radio transmission.

If it is selected to carry the site MCCH, the 'broadcast' data is transmitted and mobiles can

register.

As soon as the SUPIP board is initialised it transmits synchronisation packets on the IP

network (rhythm of about 30 milliseconds).

When a COM board is programmed as a T2 interface with a switchboard, it transmits

connection data and, as soon as it receives data, the switch declares the resource as available -

the link representing this connection changes to green on the standby screen of the network

management terminal .

NeTIS MAINTENANCE GUIDE – Version 1.1 31/139

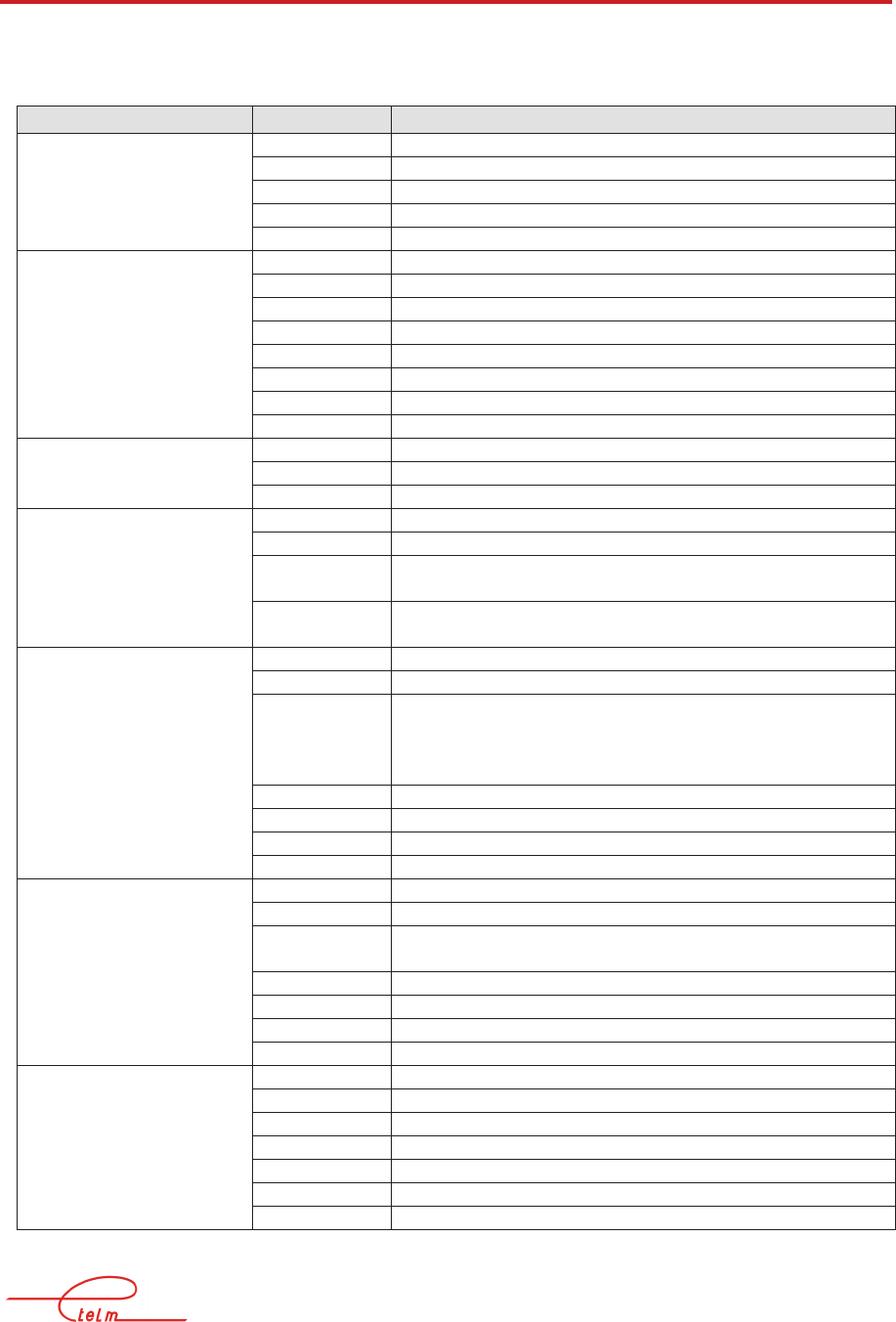

3.3 Normal operations

During normal operation the state of the indicators is as shown in the table below:

Board Indicators state

ALIM 220v On

28v On

12v On

5v On

-12V On

CPUBDT + 5v On

TLY Slow flashing

LOC Off

TFR Off

+ 5v On

INT Fast flashing

ACT Slow flashing

MCCH On for the active switch

SUPIP + 5v On

INT Fast flashing

ACT Flashing if phone traffic (reception of phone blocks)

CCT2 + 5 v On

MFR Slow flashing

D1 Off / flashes during communications (reception of phone

blocks) - odd channels

D2 Off / flashes during communications (reception of phone

blocks) - even channels

COM3 or COM4

Site communication mode

COM3

Site communication mode

+ 5v On

ACT Slow flashing

RX A On = Frame locked in G703

or clock presence in V11

flashes if star network

fixed if ring network

ERR A Off – bit error in G703

RX B

ERR B On if no link

COM3 or COM 4

T2 mode

+ 5v On

ACT Slow flashing

RX A On = Frame locked in G703

ERR A On

RX B Off

ERR B Off

COM S0 + 5v On

ACT Slow flashing

RX On = synchronisation with remote equipment

B1 On during communication

B2 On during communication

NeTIS MAINTENANCE GUIDE – Version 1.1 32/139

3.4 Removing subsets

3.4.1 P

LUG

-

IN MODULES

The different modules must be plugged in or removed when power is off.

Before removing a module, disconnect the eventual coaxial connections from its front face.

To remove a module, first remove the screws from the four corners of the front face of the

module before gently extracting it by pulling it forward using the extraction handles.

Before any interventions inside the chassis, the mains or 48V input at the rear of the chassis

must be disconnected.

The power supply module has an auxiliary connector (mains input) which must be

disconnected before completely extracting the block.

Plugging a block back in must be done gently but firmly; once the block is correctly engaged

on its connector, push hard on the set to place it correctly.

3.4.2 R

EAR FACE

The rear face is removed by unscrewing the 4 screws at each corner of the rear face; the

connection cables are long enough to be able to lay the face on a flat, cleared surface.

3.4.3 V

ENTILATORS

Access to the ventilators differs depending on the rack or box versions: for the rack version,

the mains power input located to the rear must be disconnected and then the rack mounting

screws must be removed in order to extract the entire block from the front.

In the box version, access to the ventilators is from the bottom: remove the screws on the

sides and then lift the entire appliance; the lower part comes away.

3.5 Diagnosis and maintenance

WARNING: putting a switch in test mode can cause major radio disturbances both on the

network on which the station is working and on other networks in the region (frequency

changes) - it is therefore strongly recommended to disconnect the base stations before any

tests

NeTIS MAINTENANCE GUIDE – Version 1.1 33/139

3.5.1 G

ENERAL POWER FAULT

No indicators on:

Check the general fuse located to the rear on the main power input block

Check that there is 220V

Check the position of the switch located on the rear face

If everything is correct:

Unplug the power supply module

Disconnect the auxiliary mains supply cable from the module

Check for 220V on this disconnected connector

If everything is correct: the power supply module is out of order

Otherwise the internal mains wiring or the switch or the mains filter are

defective

Only the 220v indicator is on the power supply module:

Unplug the power supply module

Power off and on again

If the indicators turn on again there is either a short circuit on a power supply, or all the

circuits were put on stand-by following a general power surge.

One or mode indicators on the power supply module are off:

Turn off the switch

Wait for a few seconds

Turn the appliance back on

If the indicators are back on: it was a power overload that caused the corresponding power

circuit to switch to safety mode, check consumption

If the fault persists, turn the appliance off and unplug all the modules using the defective

voltage;

Turn the appliance back on

If the fault persists, the power supply module is defective.

If the fault disappears, plug in the removed modules one by one (powering off between each

one) in order to isolate the defective module

3.5.2 P

OWER FAULT ON MODULE

The power supply indicator on the module stays off even though the 5 volt indicator is on the

power supply module:

Each module has a fuse soldered to the 5 volt input, close to the 96 point Europe connector. If

this fuse is broken, it is possible to replace it and closely watch when powering back on; if the

fuse breaks again, the module must be returned for repair.

Some modules also have fuses on other voltages; when these fuses break it is not shown by

the power supply indicator (which only indicates the presence of a +5 volt power supply).

NeTIS MAINTENANCE GUIDE – Version 1.1 34/139

3.5.3 C

LOCK FAULT

A high number of defects can have their origin in a clock fault; they should therefore be

checked systematically before any research on the other signals.

*Check on one BS in the network depending on your measuring bench:

With a digital TETRA bench measure the frequency error at the UCM or PA output; it

should be less than +-100Hz. If this is not the case, check the clocks.

With an analogue bench, check the frequency error at the UCM or PA output; it

should be less than +-100Hz. To do this keep the 2.25 KHz test button on the face of

the UCM pressed down in order to observe a pure offset carrier compared to the TX

BS frequency of 2.25 KHz.

If this is not the case, check the clocks:

-If the SWITCH is synchronised on the GPS signal, then check the rhythm of the GPS

indicator on the CPUBDT board of the SWITCH

-If the SWITCH is synchronised on its own LO (local oscillator), then adjust the CPUBDT

LO using the potentiometer on the face (small hole)

The general check of the clock signals is carried out from the front face of the CPU_BDT

module using the selector located on the top.

NeTIS MAINTENANCE GUIDE – Version 1.1 35/139

All the clock signals must be perfectly recurrent, stable and exempt from jitter.

Check in the following order:

Position 7: TETRA clock symbol 18 KHz

Position 5: clock time slot 70 Hz

Position 4: clock frame 70 / 4 Hz = 17.5

Position 3: multiframe 1.02 second (18 frames)

NeTIS MAINTENANCE GUIDE – Version 1.1 36/139

4. NETWORK FAILURE SCENARIOS

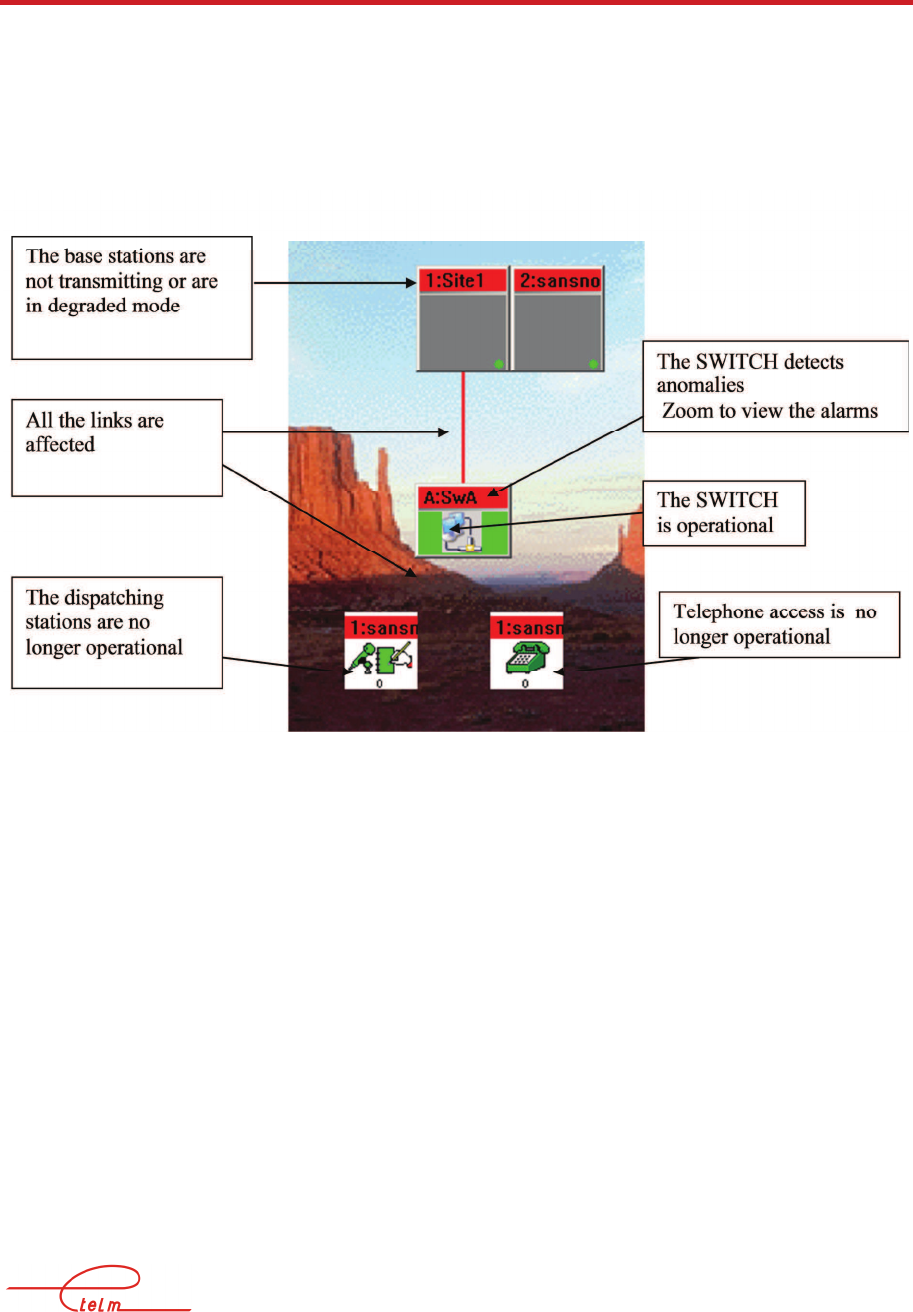

4.1 None of the network equipment is operational

The standby screen on the network management terminal indicates that the switch is no

longer connected.

The base stations are not transmitting or are in degraded mode.

The dispatching stations are no longer operational.

Telephone access is no longer operational.

First check the position of the switching unit if the installation has one. If everything is

normal the fault probably originates from the CPU board. Reset it by pushing a pointed object

into the hole on the front face of the CPU board.

If, after the reset, everything seems to operate correctly, check that the link with the service

network management terminal is correct (view the network management terminal's standby

screen). If the installation has a switch unit, check its correct operation because the switch

may have occurred - this test is carried out by cutting the junction on the COM2 port of the

active switch with the switch unit (the other switch must, of course, be operational for the

test).

If the installation does not seem to start up, connect a VGA screen to the front face of the

CPU board and check its indications after resetting. The software loading and programme

launch steps are indicated. After the software is loaded, indications are given of the resources

detected by the CPU board - check that the displayed resources correspond to the various

boards located in the chassis. If the run fails, carry out software reload.

If the problem comes from the non-loading of the OS, change the flash board and reconfigure

the network

NeTIS MAINTENANCE GUIDE – Version 1.1 37/139

If, after re launch, the service console indicates that the switch connection is correct, refer to

the following case where only the network management terminal is operational on the

network. Otherwise, after checking the correct operation of the network management terminal

and the link, change the CPU board.

4.2 The network management terminal (NeTIS-M) is the

only operational equipment on the network

The network management terminal’s standby screen shows that the switch is connected and

that no other equipment is connected (base station, telephone) or these indications are

random.

The base stations are not transmitting or are in degraded mode.

The dispatching stations are no longer operational.

Telephone access is no longer operational.

This is probably a fault in the CPU board, or a problem with the switch internal bus; in order

to find out, disconnect the switch extension unit if it has one and reset the CPU board:

If all the resources connected to the main switch unit are operational again, the fault

comes from the extension (or the cable connecting it)

Otherwise remove all the communications boards, the codec boards and the SUPIP

board from the chassis. Reset the CPU board and check that it detects no resources

(except for the time base board); reconnect a communications board and check that it

is detected; if it is not detected, the CPU board is defective.

If the resource is detected, continue reconnecting the boards one by one and check

each time that they are detected correctly. If a board is not detected or is detected with

a wrong location number, that board is defective and may have caused a major

disturbance to the entire equipment.

4.3 No equipment on the network is operational except for

the network management terminal (NeTIS-M) which

NeTIS MAINTENANCE GUIDE – Version 1.1 38/139

indicates that switch is operational and all the BSs out of

order

The network management terminal’s standby screen shows that the switch is connected and

that no other equipment is connected (base station, telephone ...) or these indications are

random.

NeTIS MAINTENANCE GUIDE – Version 1.1 39/139

The resources are correctly detected by the CPU

Check the state of the 'Rx’ and 'ERR’ indicators on the communications boards (COM)

If all the indicators are in a normal state, the problem comes from a resource assignment error

Reload the equipment configuration file from the network management terminal (download).

NeTIS MAINTENANCE GUIDE – Version 1.1 40/139

4.4 BSs answer correctly on the NMT, but mobiles do not

register onto the network.

The base stations reply normally to a 'zoom' request from the service network management

terminal.

Mobiles do not register into the network.

In the event file there are no mobile registrations; the messages below cannot be found in the

log.

In this specific case there is necessarily a problem on the site due to the absence of

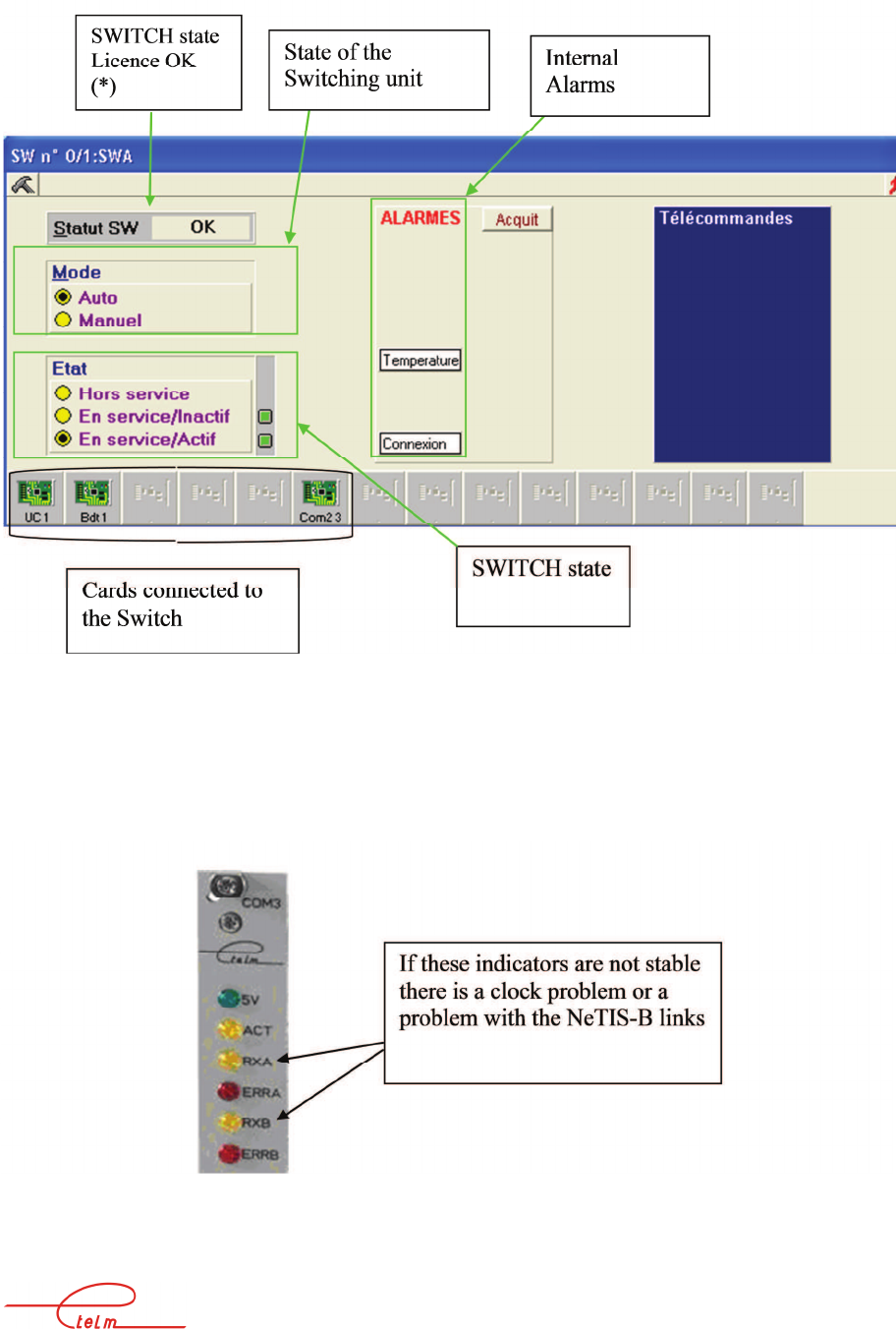

registration.