Cisco Systems BTS-R3 Broadband Data BTS User Manual Appendix Pt 1 40 00047 08 F I C TTA

Cisco Systems, Inc Broadband Data BTS Appendix Pt 1 40 00047 08 F I C TTA

Contents

Manual app 1

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 109

October 23, 2003

Appendix A: Sample Statement of Work (SoW)

The following is an example of a Statement of Work. The Statement of Work outlines the general

activities that must be conducted in order to complete the installation and commissioning tasks for a

Ripwave Base Station.

Example:

Statement of Work for Standard Installation Services

The following statement of work will be used to outline the areas of responsibilities for the Navini

Networks antenna (known as the RFS) and Base Station (known as the BTS) installations to be

completed with Navini Networks Client (referred to as Client in this document). Client may choose

to hire a contractor or tower crew to assist with its activities. Navini Networks has no formal

contract relationship with the contractor, who will be managed by Client. The following work items

are suggested content only - - final scope and terms to be negotiated directly with Client. Navini

Networks support personnel will be on site for the entire installation and commissioning process,

and will provide technical expertise, information, and recommendations with respect to site design

and installation.

It is recommended that contractor have a Non-Disclosure Agreement (NDA) in place with Client and

Navini Networks prior to execution of work. Contractor shall not publicly disclose any information

concerning this deployment or trial with any other parties, unless approved in writing in advance by

Client and Navini Networks.

Navini Networks

1. Provide Field Engineer to consult with Client and Contractor for planning efforts. Review

Site design sketches and BOM prepared by others.

2. Review network architecture information (connection diagram and logical addresses) prior to

start of installation.

3. Review Sweep results with Client and contractor. Sweep to be provided of RFS after

shipment, of coax cables and RF path on tower, and of cables and RFS after installation,

before power up.

4. Review AC and DC power system installation. Review DC power system test with Client

and contractor.

5. Review backhaul circuit installation test results with Client.

6. Review GPS antenna and cable installations.

7. Review and Verify Cable and Antenna System Installation Work

8. Site walk with contractor and Client for Punchlist.

9. Load EMS software on Client supplied workstation, and verify connectivity to BTS.

Ripwave Base Station I&C Guide Navini Networks, Inc.

110 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

10. Provide BTS installation – Chassis and Cards.

11. Apply power to BTS and perform all power up, BTS calibration verification checks,

commissioning and initial testing of Navini Networks system. May use EMS on local laptop.

12. With assistance of Client, Perform Drive Test / Coverage Verification.

13. With assistance of Client, perform data rate testing at mutually specified locations – 15 for

Omni, 5 for each panel RFS.

14. With client, integrate BTS into backhaul network and verify operation.

15. Closeout / Customer Acceptance package, including inventory of hardware.

16. Navini Networks to provide own tools and test equipment.

17. Clean job site daily.

Client / Contractor Work Items

1. Perform Site survey at each site.

2. Prepare Installation sketch and Bill of Materials (BOM) for each site. Note that these are not

sealed construction drawings.

3. Client / Contractor Site Design and Bid Walk.

4. Material Procurement.

5. Acquire building permits.

6. Inside Network cabling from demark to BTS rack

7. AC power installation (provide dedicated 115 VAC 20 A circuit for each BTS, dual outlet

receptacle).

8. Air conditioning work or other hut electrical work.

9. 24 VDC rectifier installation, cabling to BTS chassis, cabling to AC circuit breaker. Test 24

VDC system (note: do not apply power to BTS).

10. Mount 19” TELCO rack inside hut (base anchors, or overhead brackets or both)

11. Provide core drilling and furnish and install feed through panel for coax cables, unless

already existing. Seal holes using similar materials to other existing feed-through at each

site.

12. Install grounding inside hut for rack and 24 VDC system. Install ground bus bar inside hut

entry per drawings. Install ground bus bars on antenna structure and ground coax cables per

sketch.

13. Install and apply coax cables and connectors. This includes main coax runs on tower, plus

coax jumpers at antenna and at hut, as specified by drawings. Recommend and Install all

cable hangers and supports, and grounding, per standard practice in use at tower location.

Install surge protectors per design sketches and BOM.

14. Sweep test coax cables at designated sweep frequencies.

15. Install power and data cable from antenna to BTS.

16. Weather seal all outside connections.

17. Recommend, furnish and install mounting structure (arm assembly) to stand-off Navini RFS

from tower. Standoff assembly to include pipe mount for antenna mount. Install Navini RFS

on arm on tower. Connect to coax cables and provide sweep of cable / RFS assembly.

Provide photographic documentation of tower top installation work.

18. Provide equipment and cable labeling as required.

19. Install (2) GPS antennas on ice bridge (or other agreed upon location). Furnish and install

any required brackets or pipe mounts. Install GPS coax cables and connectors from GPS

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 111

October 23, 2003

antenna to BTS.

20. Site walk at completion with Client and Navini, create Punchlist; clear applicable punchlist

items.

21. Arrange disposal of trash

22. Provide RF coverage analysis plots before start of installation. Provide model tuning, if

required.

23. Provide architecture document before start of installation, including connection diagram and

logical network element assignments (IP addresses, PVCs, etc.).

24. Set Up and Verify all network equipment and backhaul circuits.

25. Set Up and Verify Operation and connectivity of EMS computer.

26. Provide one resource to assist with drive testing and location data rate testing.

27. Provide all end user / CPE provisioning in EMS after initial testing.

28. Provide all end user interface and troubleshooting.

29. Monitor EMS / alarms. Forward trouble issues to Navini call center.

30. Contractor and Client to provide own tools, computers, and test equipment.

Ripwave Base Station I&C Guide Navini Networks, Inc.

112 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 113

October 23, 2003

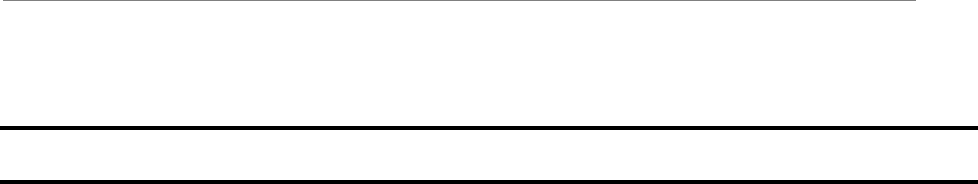

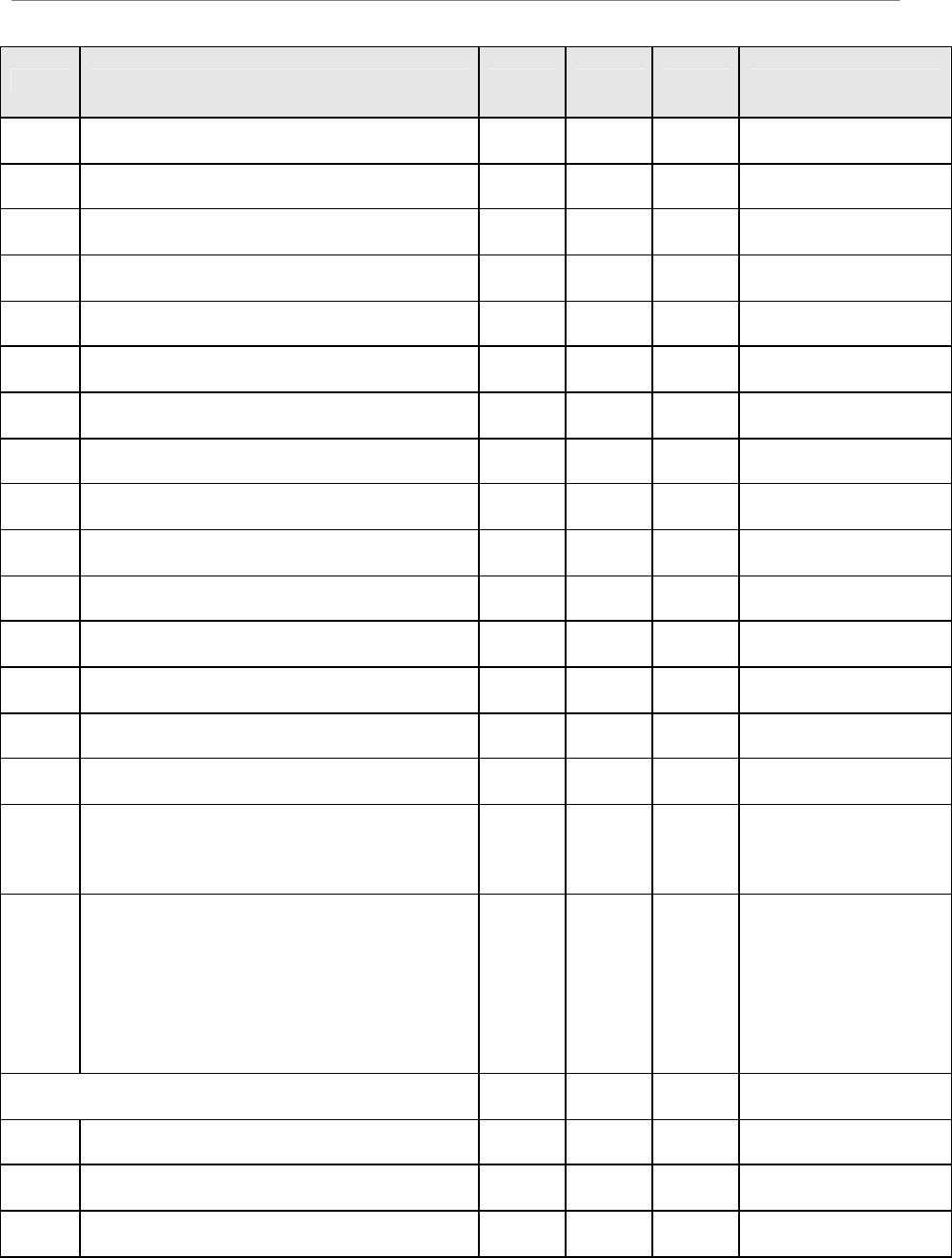

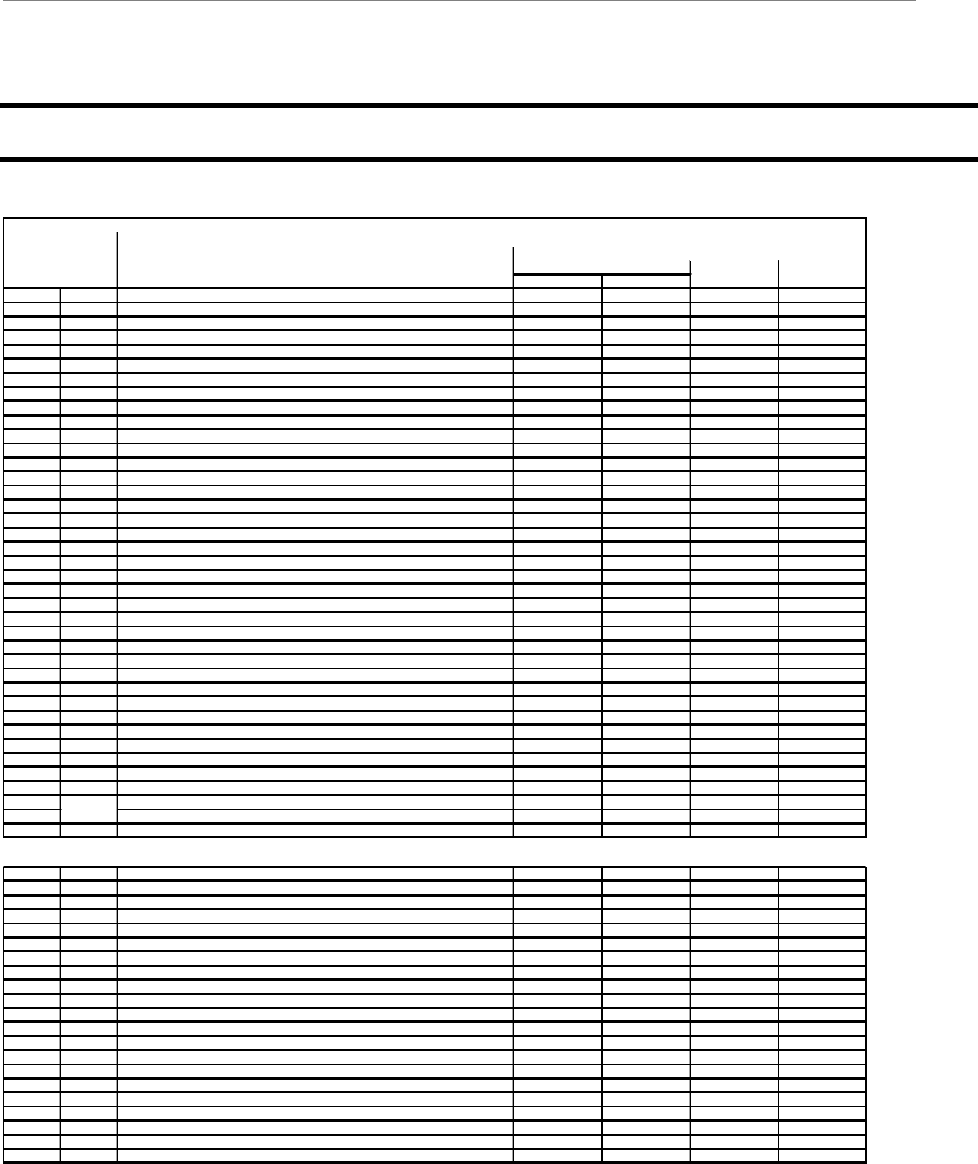

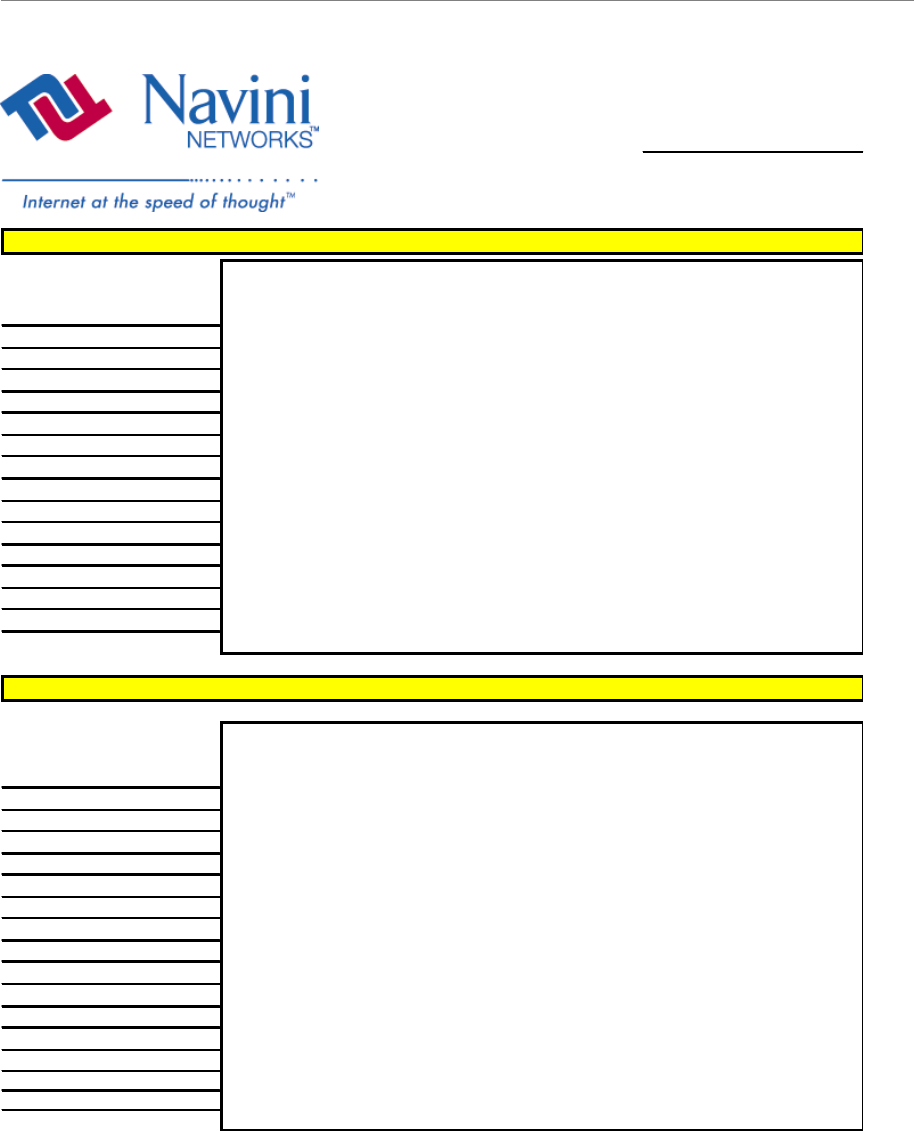

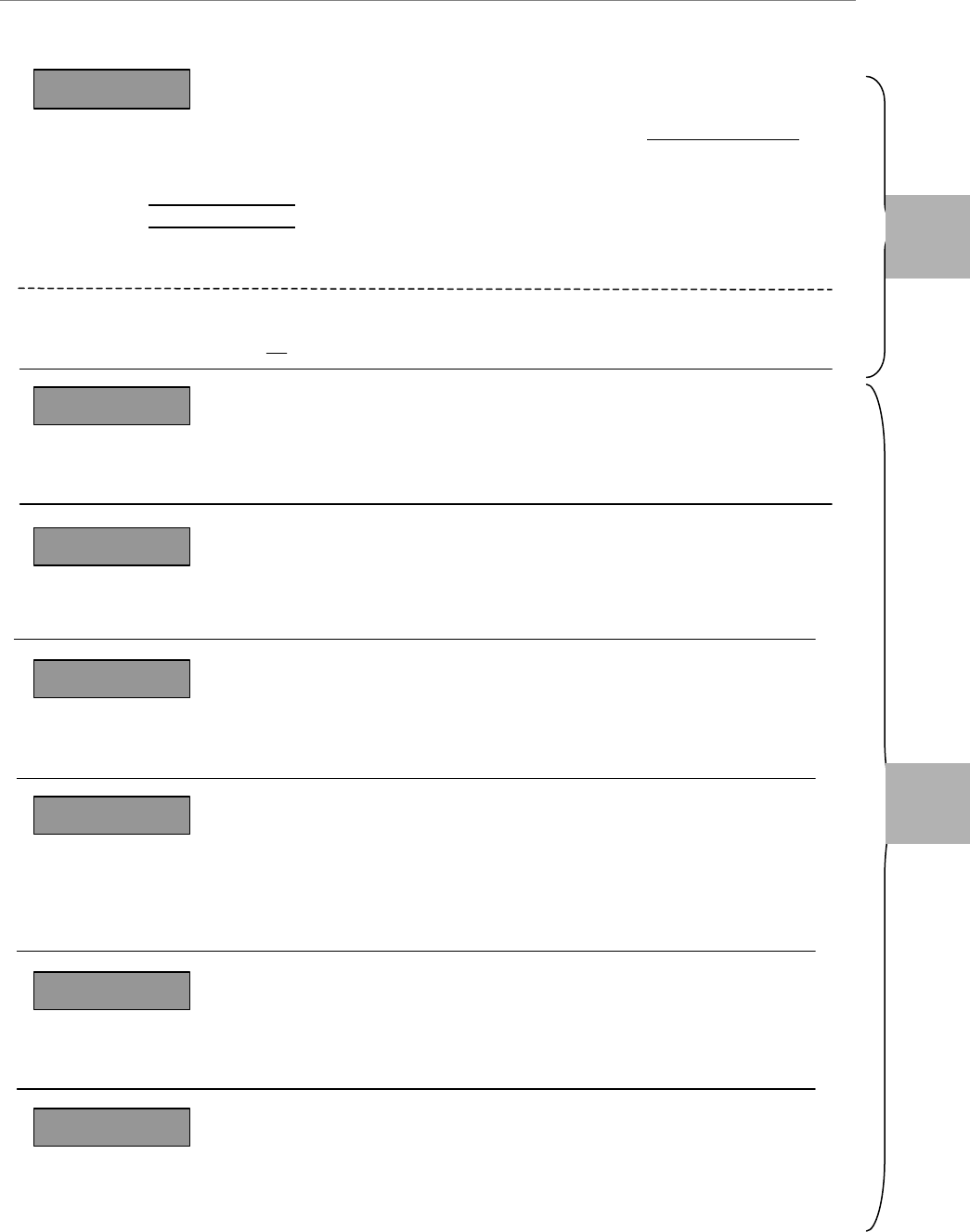

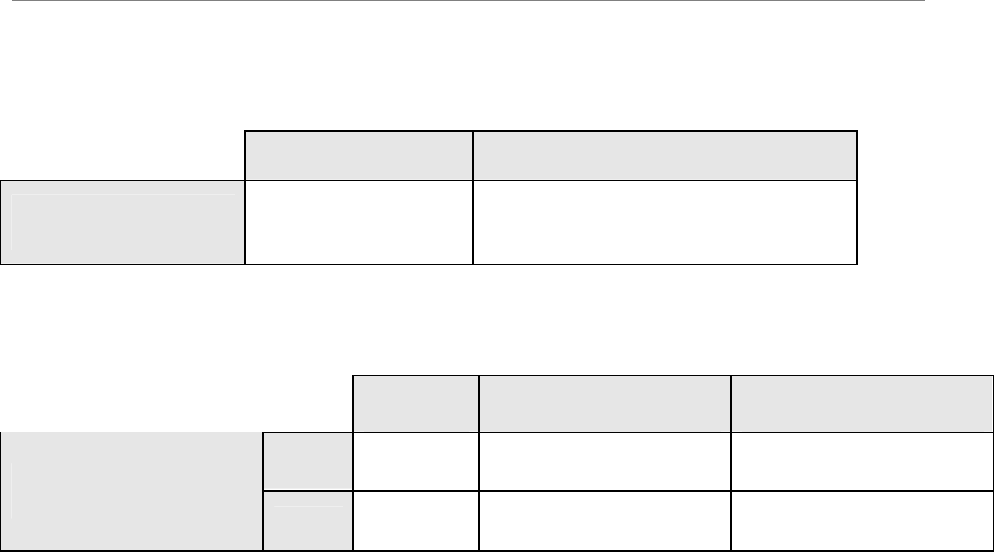

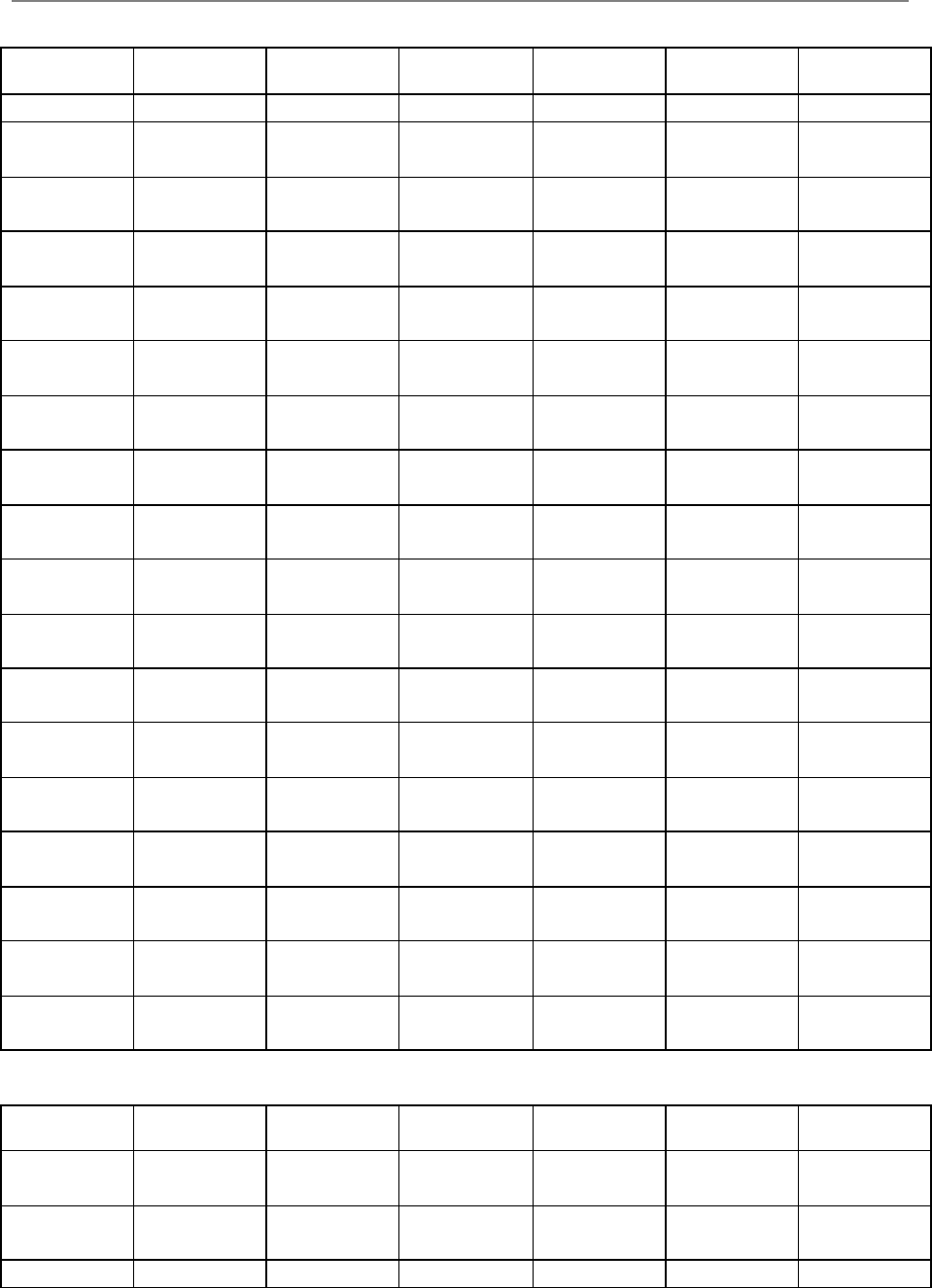

Appendix B: Sample Responsibility Assignment Matrix

(RAM)

The following is an example of a Responsibility Assignment Matrix (RAM). The RAM is a tool for

capturing who will do what to get systems deployed and turned up. It provides an easy-to-read and

follow tabular format. Each of the activities in the list must be addressed in order to complete the

installation and commissioning tasks for a Ripwave Base Station.

1 = Primary Responsibility S = Supply

2 = Secondary Responsibility I = Install

Item #

Task / Activity Navini Client Other Notes

MARKET PLANNING and RF ENGINEERING

1 Develop coverage objectives 1

2 Provide Hardware Specifications 1

3 Provide Link Budget 1

4 Prepare Preliminary Coverage Plots 2 1

5 Interference Analysis / Noise Floor 2 1

6 Link Specific Channel Assignments 2 1

7 Review / Approve RF Design 2 1

8 SCT Filing fees 1

9 SCT licensing / clearing 1

10 Contract RF consulting engineering 1

11 Obtain SCT Test Permit 1

NETWORK ENGINEERING & BACKHAUL

1 Network Requirements 2 1

2 Network Architecture 2 1

3 Provisioning Guidelines 1

Ripwave Base Station I&C Guide Navini Networks, Inc.

114 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Item #

Task / Activity Navini Client Other Notes

4 IP / data Address Assignment / management 1

5 Review / Approve Network Design 2 1

6 Network Architecture – backhaul 1

7 ATM layer Provisioning / management 1

8 Order Circuits 1

9 Order equipment for backhaul / interface 1

10 Backhaul Network Test 1

SITE ACQUISITION

1 Identify BTS candidates in search ring 1

2 Identify CPE Candidates per ring 1

3 Identification of Zoning requirements 1

4 Select BTS sites 1

5 Negotiate and close lease 1

6 Pay lease costs 1

7 Obtain any building permits if required 1

8 Arrange Site Access 1

SITE DESIGN

1 Site Survey – BTS sites 2 1

2 Prepare Site Design Sketches / Layout 2 1

3 Prepare BOM 2 1

4 Review Design / Approve 2 1

5 A&E Selection and management 1

6 Prepare / approve A&E drawings 1

7 Tower Structural Analysis 1

8 Contractor Qualifications and Selection 1

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 115

October 23, 2003

Item #

Task / Activity Navini Client Other Notes

9 Contractor walk through 1

10 Obtain / Review bids / Award contract 1

11 Obtain Building permits or other approvals 1

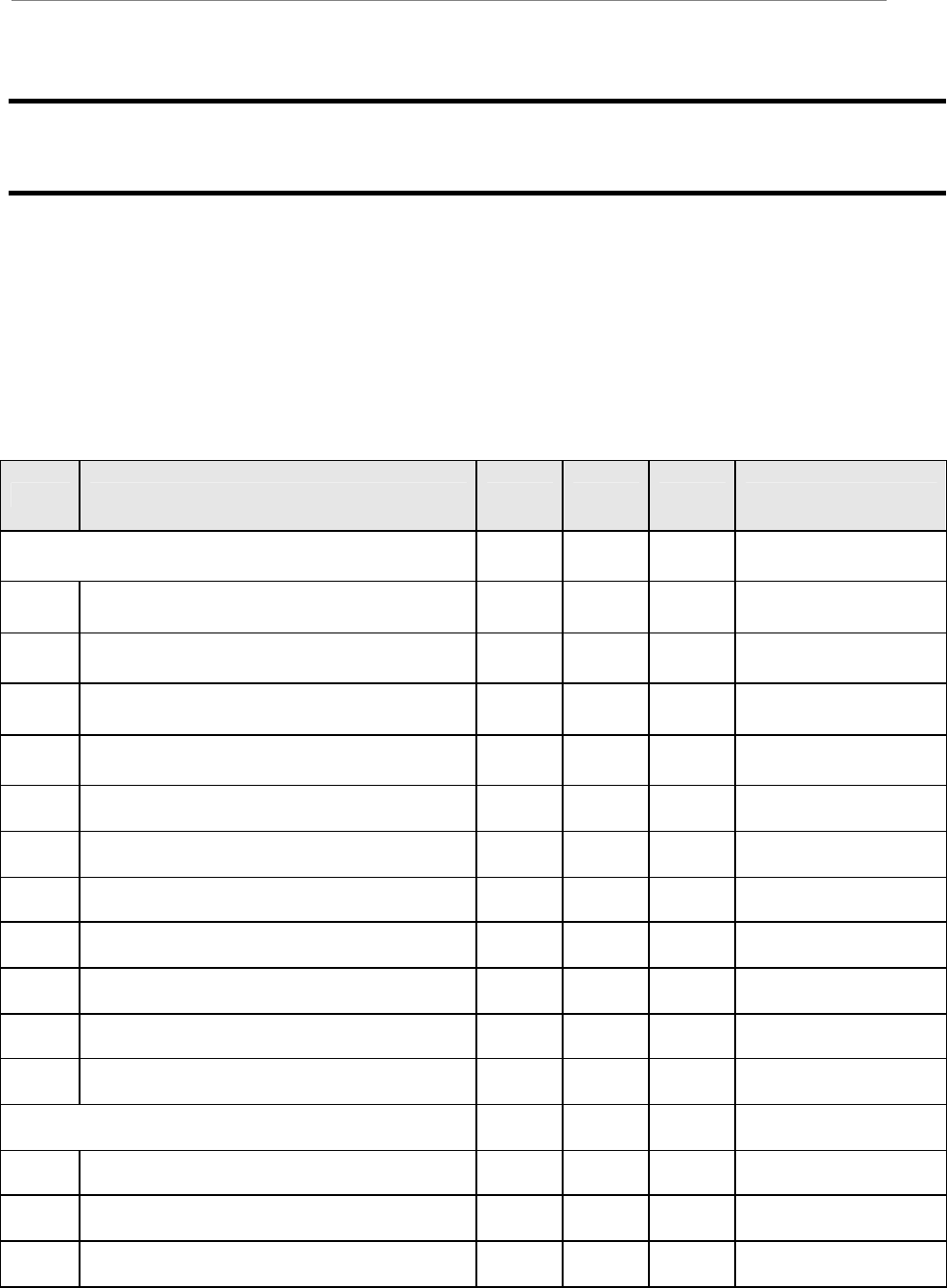

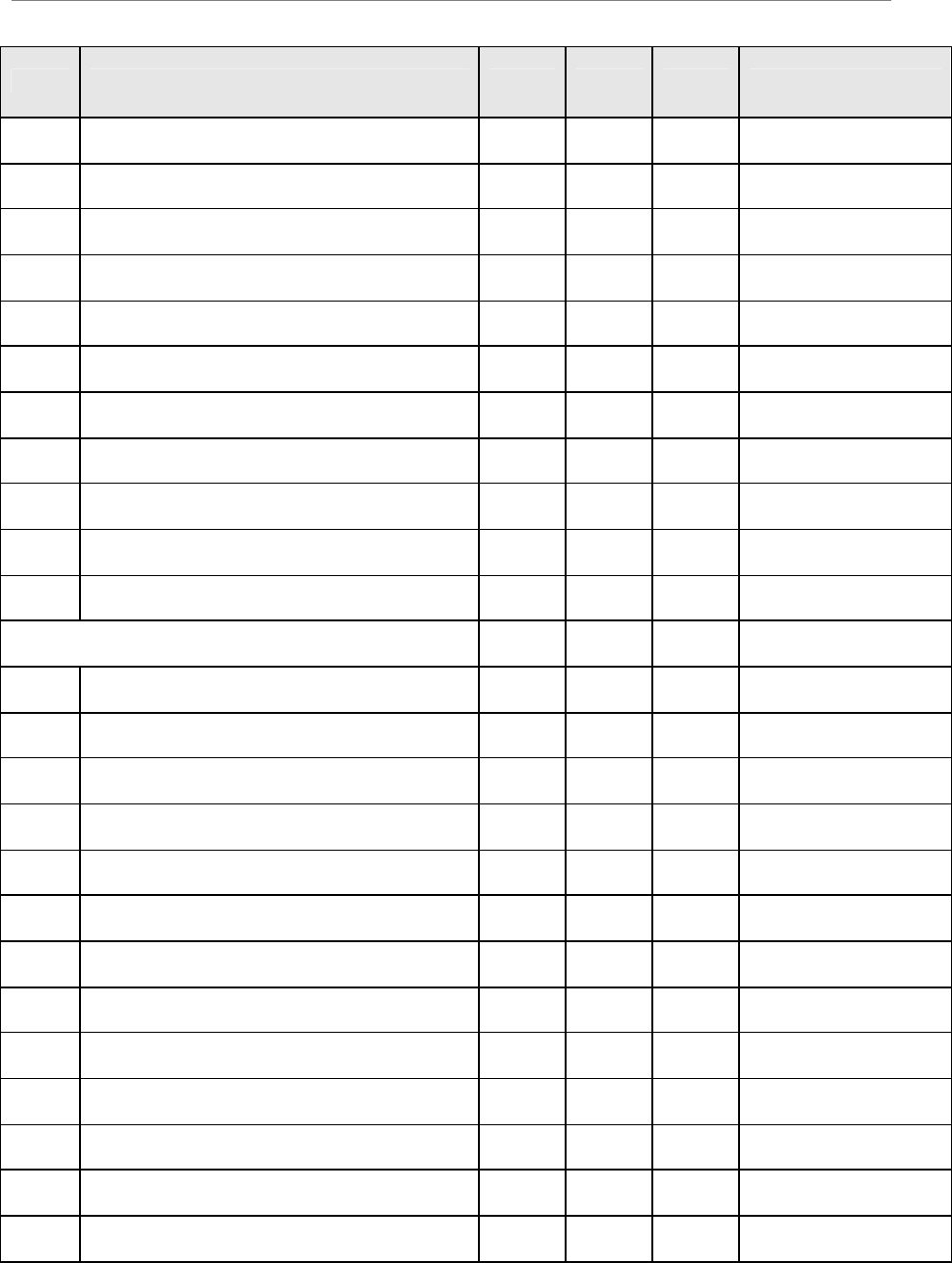

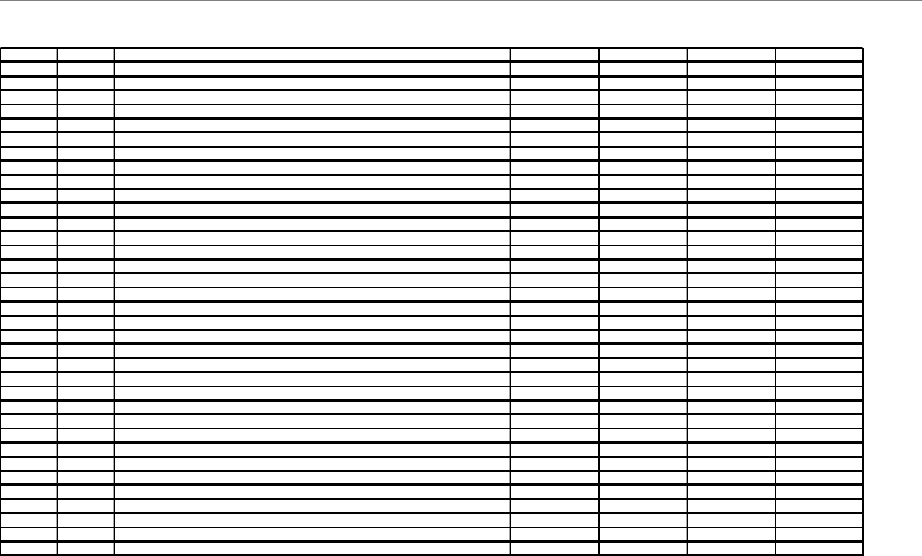

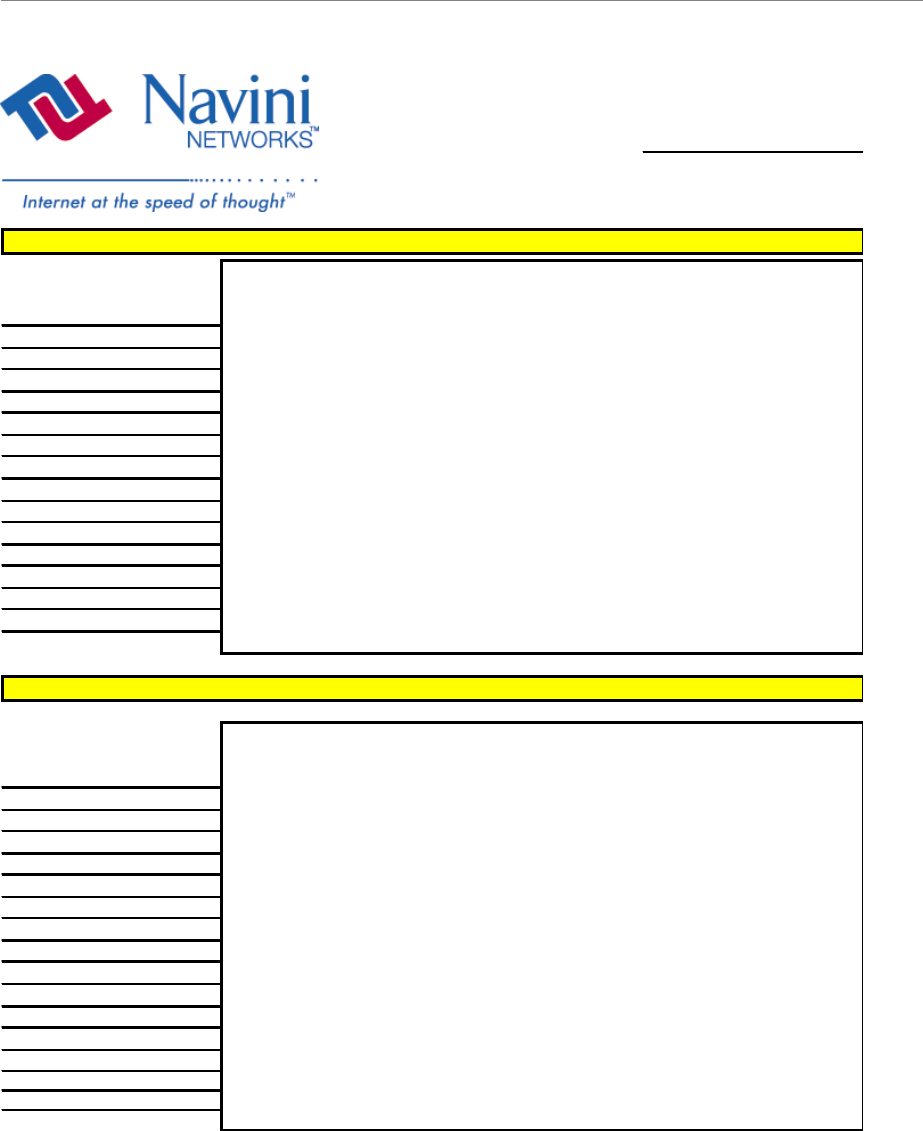

LOGISTICS / SHIPPING / DELIVERY

1 Create Logistics Plan 2 1

2 Ship Navini supplied Equipment to designated

warehouse 1

3 Deliver Equipment to Specific Sites 1

4 Disposal of Shipping materials 2 1

CONSTRUCTION / INSTALLATION

1 Antenna Mounts / brackets S, I

2 Antennas (Navini RFS) S I Navini will assist and

supervise installation

from the ground.

3 Coax Cable / Connectors S, I

4 Power / Signal Cable / Connectors (BTS to

RFS) S I 1 per BTS.

5 Ground Kits S, I

6 Surge protectors/Ground Buss Bars

S, I

Navini to supply surge

protector for the power

and data cable. Client to

supply surge protectors

for coaxial feedlines.

7 GPS 4-Way Splitters for multiple BTS’ installed

at one site. S, I 2 4-Way Splitters

needed for 3-sector

installation.

8 BTS Equipment Racks / Enclosures S, I Need to confirm indoor

installation. Enclosure

not required indoors.

9 DC Power System 24VDC @ 60 Amps for each

BTS S, I

10 Batteries / UPS S, I

Ripwave Base Station I&C Guide Navini Networks, Inc.

116 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Item #

Task / Activity Navini Client Other Notes

11 Intra – rack cabling S, I

12 Electrical Circuits S, I

13 Electrical – wiring from panel to rack S, I

14 Electrical (conduit, distribution panels, etc.) S, I

15 Environmental Equipment S, I

16 Miscellaneous Hardware S

17 BTS cages / cards S, I

18 Network Router S, I

19 Network Ethernet Switch with ATM interface S, I

20 EMS Server / workstation S, I

21 EMS client workstation (for techs) S, I

22 EMS client workstation (for Navini) S, I

23 Server for DHCP and network applications S, I

24 CPE S

25 User PC with Ethernet and/or USB Card S

26 Provide Construction Supervisor 2 1 Navini will supervise

installation of Navini

equipment.

27 Provide Installation Resources

2 1

Client contractors.

Navini will install the

BTS in the client

installed rack/cabinet.

Navini will provide

technical guidance for

installation of the RFS.

CONSTRUCTION

1 Site Preparation / Infrastructure 2 1

2 Pull Cables 1

3 Install Connectors and Grounding 1

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 117

October 23, 2003

Item #

Task / Activity Navini Client Other Notes

4 Install Surge Protectors 2 1

5 Test / Sweep Coax 2 1

6 Install mounts / brackets 2 1

7 Install Racks 2 1

8 Electrical power to Rack 1

9 Backhaul to rack 1

10 Environmental (if required) 1

11 Quality Assurance 2 1

12 Inspections / Punch List 2 1

13 Close all Punch List Items 2 1

14 Provide POTS line for technician use 1

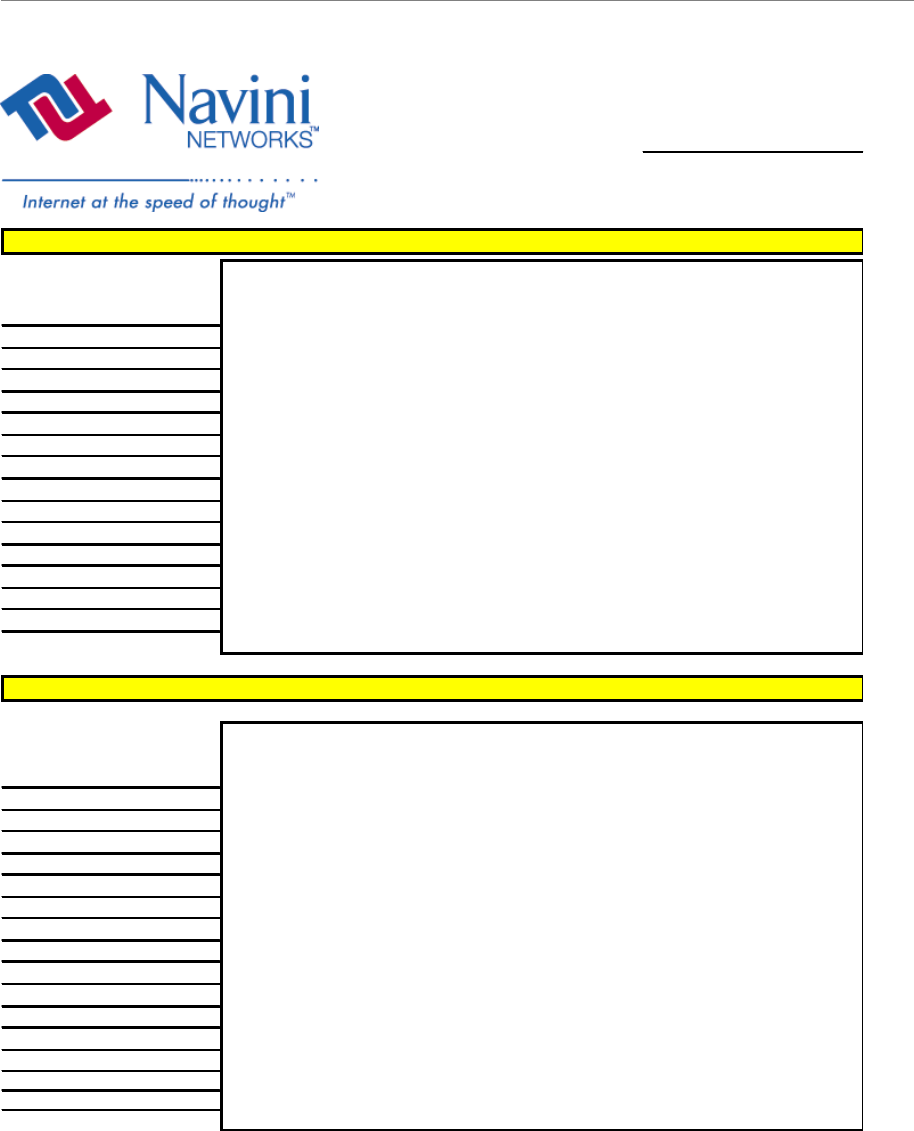

EQUIPMENT COMMISSIONING & INTEGRATION

1 Inspect / Test Cabling / Connections 2 1

2 Install Rack Mount Power System / Card Cages 1 2

3 Test DC System 2 1

4 Plug cards in BTS 1

5 Load EMS / Configure 1

6 Boot BTS 1

7 Provision EMS / BTS / CPE 1

8 Test Operation 1

9 Integrate Backhaul 2 1

10 Verify Operation 2 1

11 Router: Configure / test 1

12 DHCP Server: configure / test 1

13 EMS Client: Configure / Test 1 2

Ripwave Base Station I&C Guide Navini Networks, Inc.

118 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Item #

Task / Activity Navini Client Other Notes

14 Configure monitoring for routers 1

TESTING

1 Determine Network Test Criteria 2 1 Based on trial

agreement.

2 Determine RF Test Criteria 1 1 Based on trial

agreement.

3 Generate Acceptance Test Plan (ATP) 1 1

4 Review Test Plan 1 1

5 Supply Test Equipment

HP/Agilent E4402B Spectrum Analyzer with

Floppy Storage Option, HP/Agilent 8648C RF

Signal Generator, Tektronix TDS 3012B Scope

1 2 Some tests will utilize

built in test capability.

6 Execute Trial Test Plan and capture data 2 1

7 Provide Vehicle and Driver for System Drive

Testing 1

8 Analyze test data and write report 2 1

9 Review Report, Trial test results 1 1

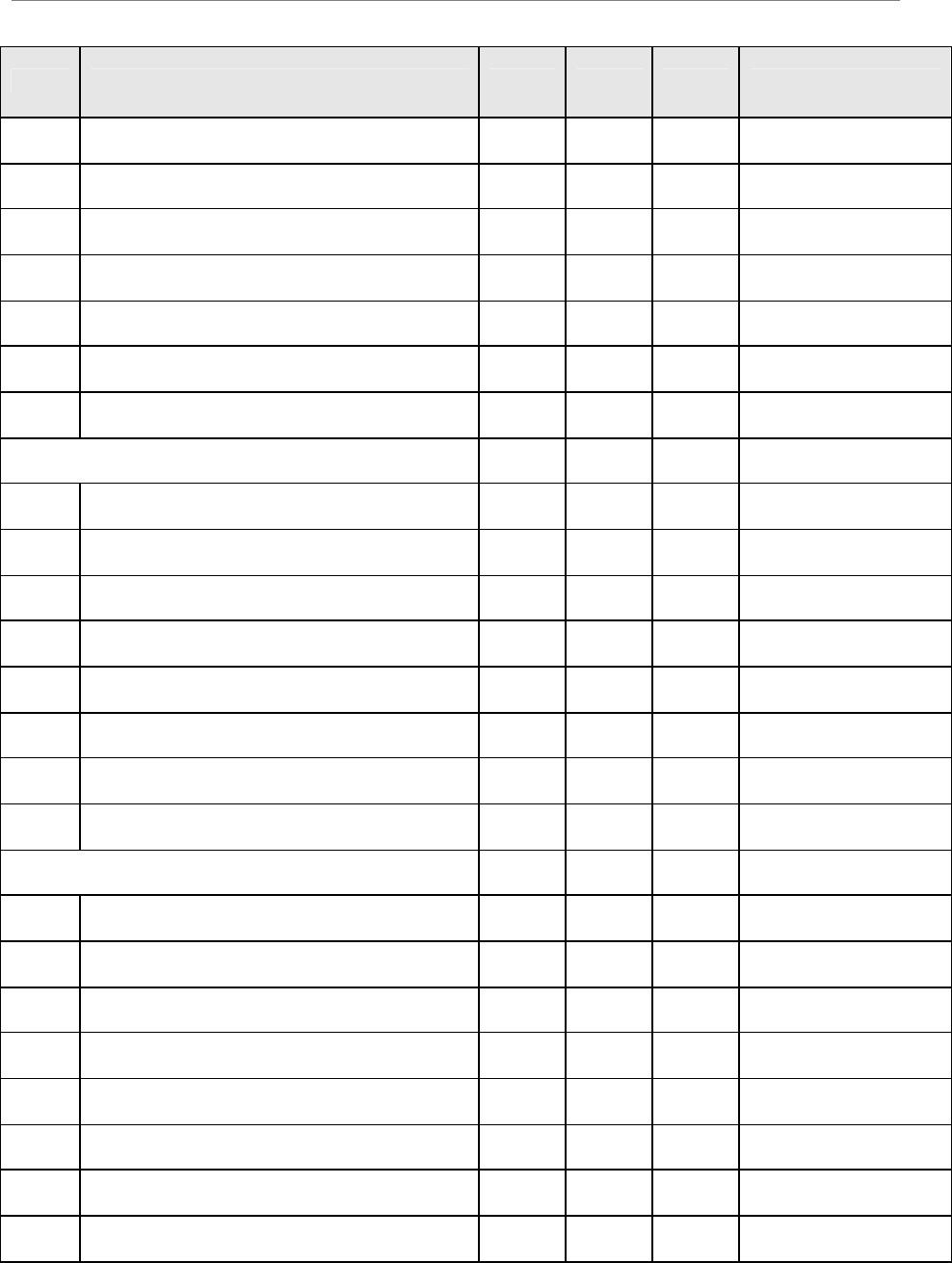

END USER ENGAGEMENT

1 Prepare End User profile 1

2 Develop User Procedures 1

3 Recruit and Sign Up Users 1

4 Distribute CPE kits 1

5 Develop User Surveys 1

6 Survey Users, collect data 1

7 Issue reports 1

SUPPORT & SERVICES

1 System Training for Service Provider 1

2 Monitor Network 2 1

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 119

October 23, 2003

Item #

Task / Activity Navini Client Other Notes

3 End User Contact (answer phones) 1

4 Fault Determination and Isolation 2 1 Client to provide Level

1 support.

5 Performance Reporting 2 1

6 Field Repairs / Replacements (if needed) 1 2

7 Shipping for Repairs / Replacements 2 1

8 Spares 1 Spares count TBD.

9 Install Hardware Upgrades (if needed) 2 1

10 Install Software Upgrades (if needed) 2 1

Ripwave Base Station I&C Guide Navini Networks, Inc.

120 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 121

October 23, 2003

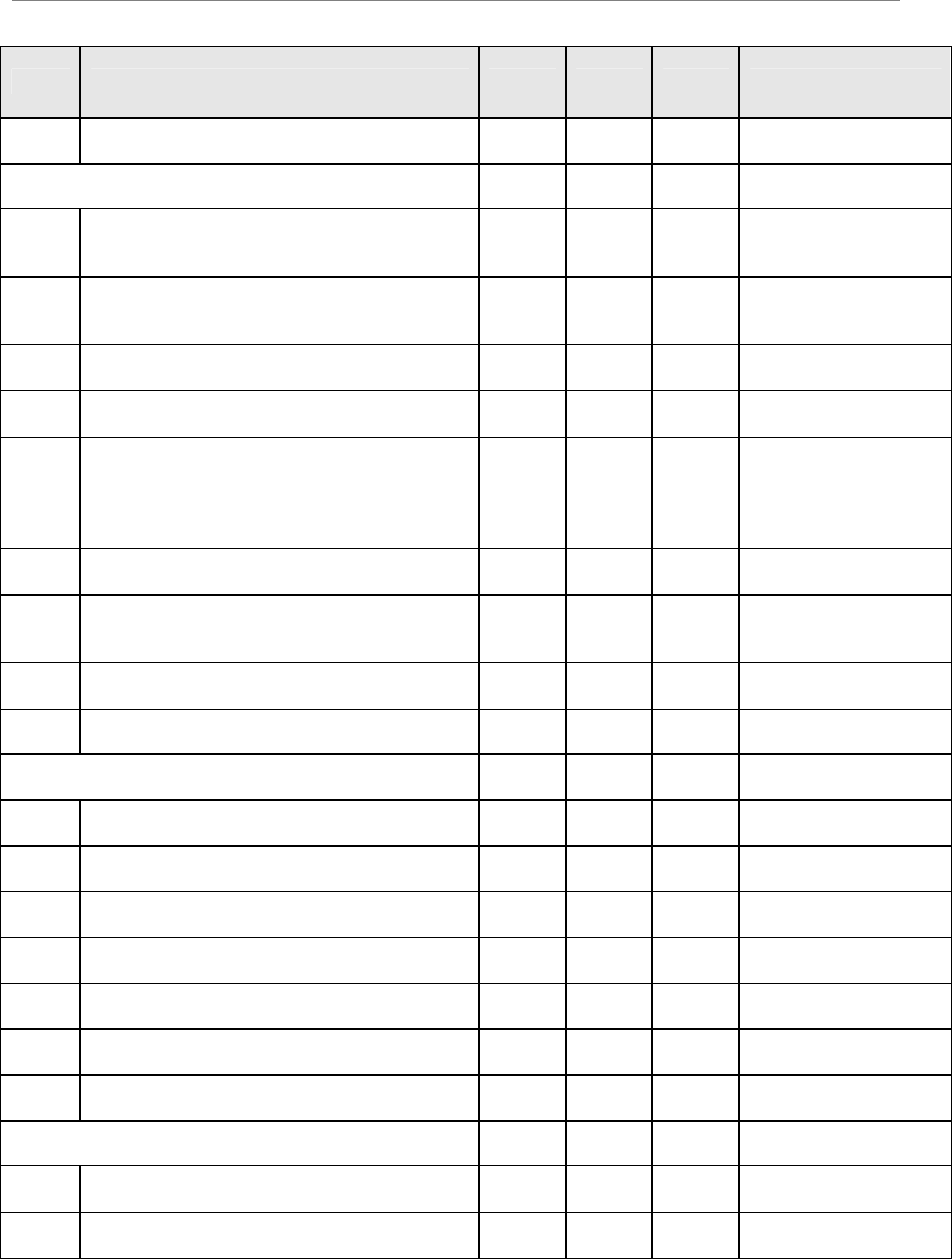

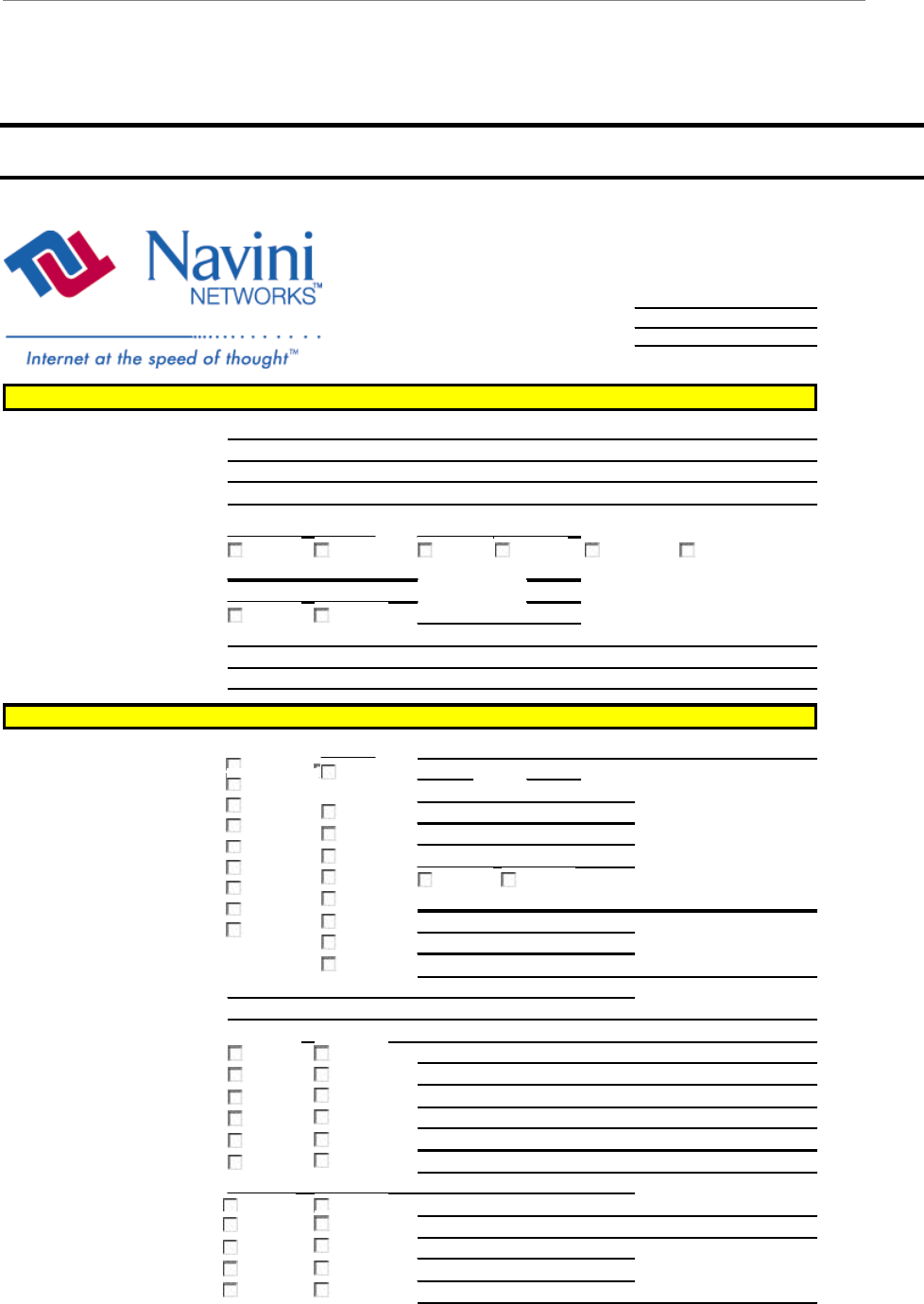

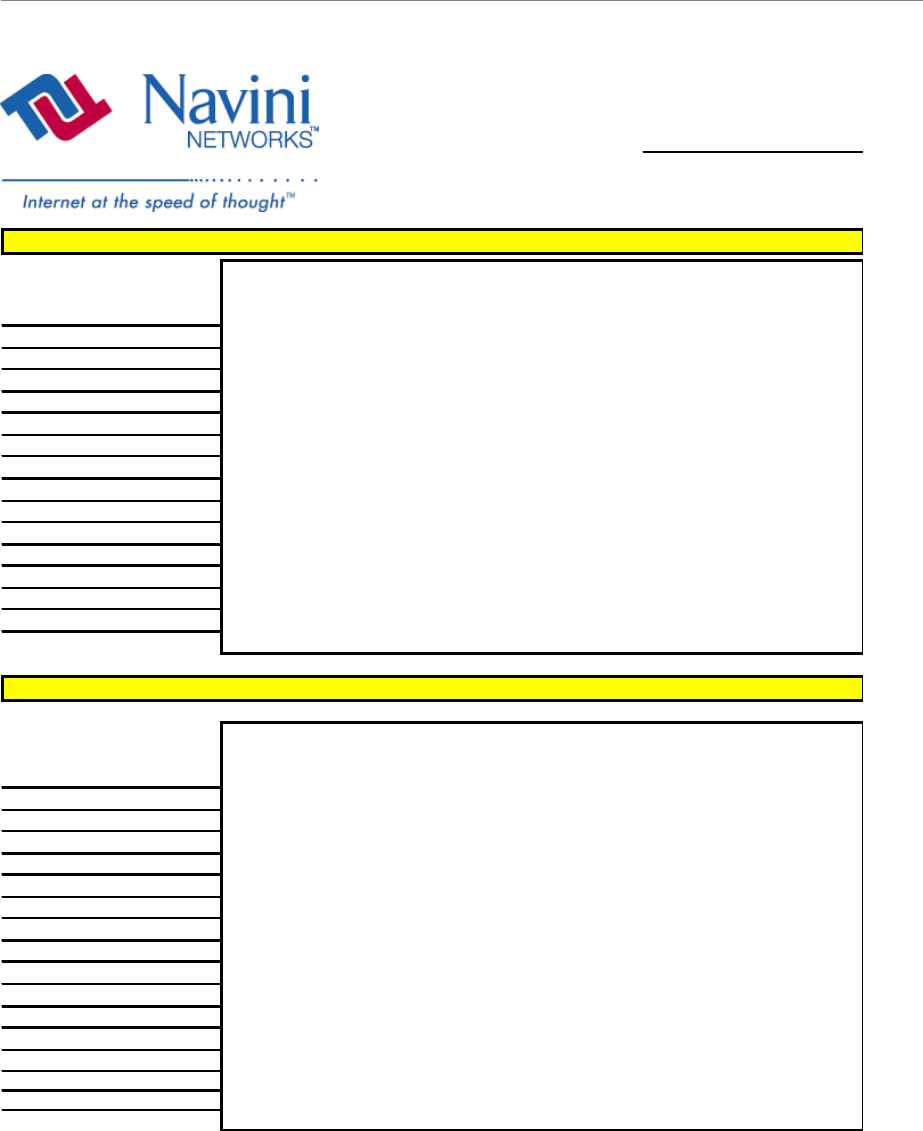

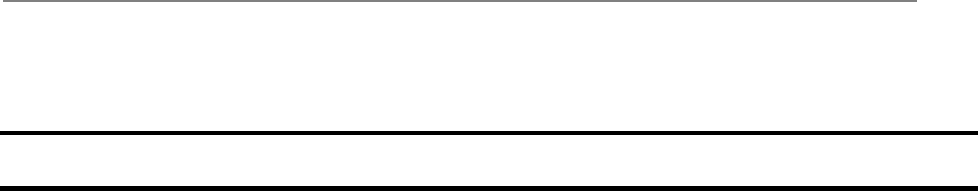

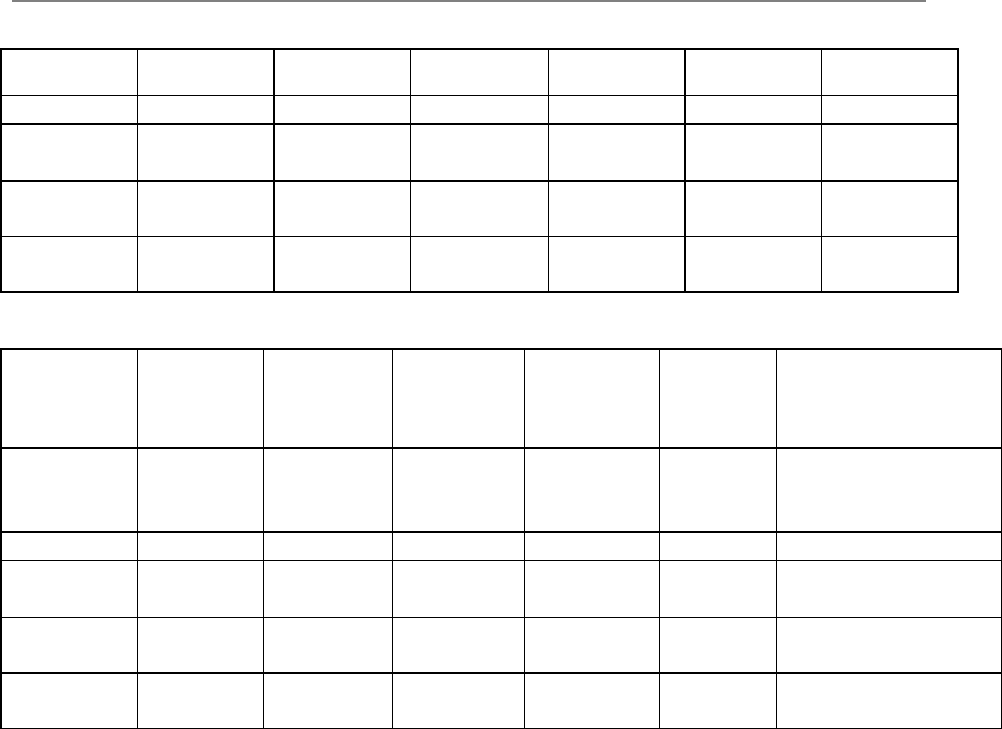

Appendix C: Sample Work Breakdown Structure (WBS)

Continued on next page.....

Site Deployment Work Breakdown

Activity

Customer 3rd Party

In-House Contractor

1System Design Criteria Established

1.1 RF Design Requirements Established

1.2 Site Configuration / BTS & RFS Requirements Established

1.3 Backhaul / T1 Requirements Established

1.4 Customer NOC / Operations Requirements Established

1.5 Network Design Requirements Established

1.6 Software Requirements Established

1.7 Hardware Requirements Established

2Site Selection Process

2.1 Candidate Identification / Site Selection

2.2 RF Propagation / Coverage Analysis

2.3 Interference Analysis / Intermod Study

2.4 Drive Test / Coverage Verification

2.5 Site Survey / Constructability Review

2.6 Zoning Analysis

2.7 FAA / FCC / ASAC Compliance Reviews / Submittals

3Site Acquisition and Leasing

3.1 Master License Agreements

3.2 Site License Agreements

3.3 Lease and Exhibit B Development Work

3.4 Rents and Payments

3.5 Entry and Testing Agreements

3.6 Phase 1 Environmental Screen

3.7 NEPA Checklist

3.8 State Historical Preservation Organization Review

4Site Design and Development

4.1 Design Coordination / Site Design Walks

4.2 A&E Drawing Package Development

4.3 Site Survey - 2C

4.4 Soils Report

4.5 Tower / Foundation Design

4.6 Structural Analysis

4.7 Permit and Const Drawing Package Review and Approval

4.8 Zoning Permits

4.9 Construction Permits - Building & Electrical

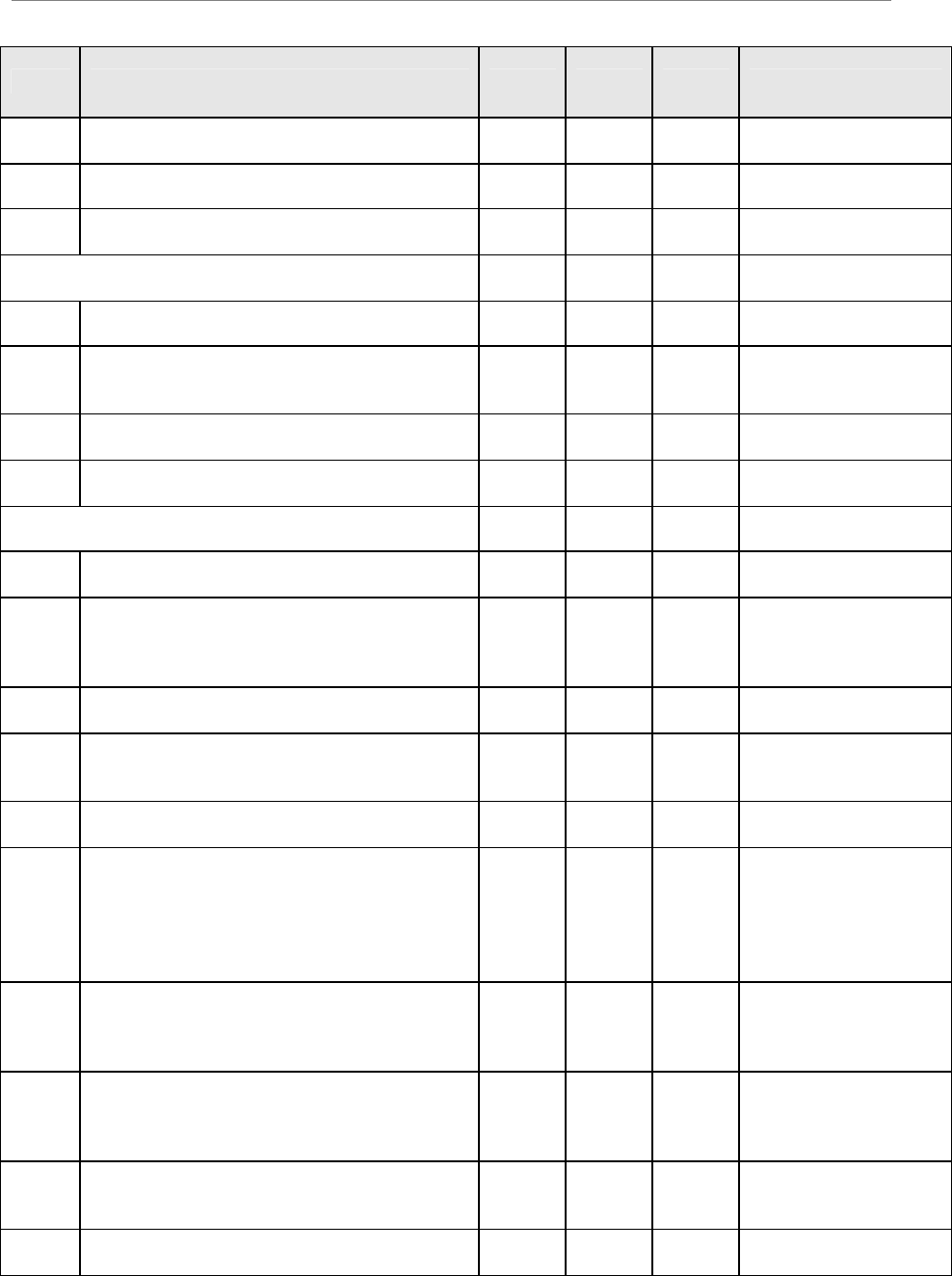

Navini Networks

Responsibility

Item No.

5Material Procurement

5.1 Bill Of Materials From Approved Construction Drawings

5.2 Vendor Selection

5.3 Bids / Quotes

5.4 Requisitions / Purchase Orders

5.5 Tower, Mounts, Lightning Protection, Lighting, Cable Ladder, Safety Climb,.

5.6 BTS - with Rack (IBTS), with Enclosure (OBTS)

5.7 RFS - Active, Passive

5.8 Cables, Connectors, Mounting Hardware, Surge Protection

5.9 AC Power Equipment

5.10 DC Power Equipment

5.11 Telco Equipment

5.12 Grounding Equipment and Materials

5.13 Delivery Coordination / Warehousing / Logistics

6Facilities Orders

6.1 Electric Power Service Order Site Walk / Engineering

6.2 Electric Power Service / Equipment Order

6.3 Telephone Service Order Site Walk / Engineering

6.4 Telco Service / Equipment Order

Ripwave Base Station I&C Guide Navini Networks, Inc.

122 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

7Site / System Construction

7.1 Vendor Selection

7.2 Bids / Quotes

7.3 Requisitions / Purchase Orders

7.4 Pre-Construction Walkthrough

7.5 Site Preperation Work - Clear, Grub, Foundation Work

7.6 Tower Delivery and Offload

7.7 Tower Installation

7.8 OBTS / Shelter Delivery and Installation

7.9 Site Materials Delivery and Offload

7.10 Power Equipment Installation

7.11 Telco Equipment Installation

7.12 Grounding System Installation

7.13 Grounding System Test and Verification X

7.14 Fencing and Security System Installation

7.15 Site Finish Work - Fencing, Landscaping,…

7.16 Punchlist Construction Work

7.17 Closeout / Customer Acceptance - Site Construction

8Equipment Installation Work

8.1 Material Delivery to Site

8.2 Install RFS(s)

8.3 Install Antenna System - Cable, Supports, Surge and Grounding Protection

8.4 Test and Verify Cable and Antenna System Installation Work X

8.5 IBTS Installation - Shelves, Cards, Power, Grounding…

8.6 AC Power Equipment Installation and Testing

8.7 DC Power Equipment Installation and Testing

8.8 Telco / T1 Equipment Installation and Testing

8.9 BTS Testing

8.10 EMS / Customer Operations Equipment Installation

8.11 Punchlist Installation Work

8.12 Closeout / Customer Acceptance - Equipment Installation Work

9System Testing / Optimization

10

Customer Acceptance / Turnover

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 123

October 23, 2003

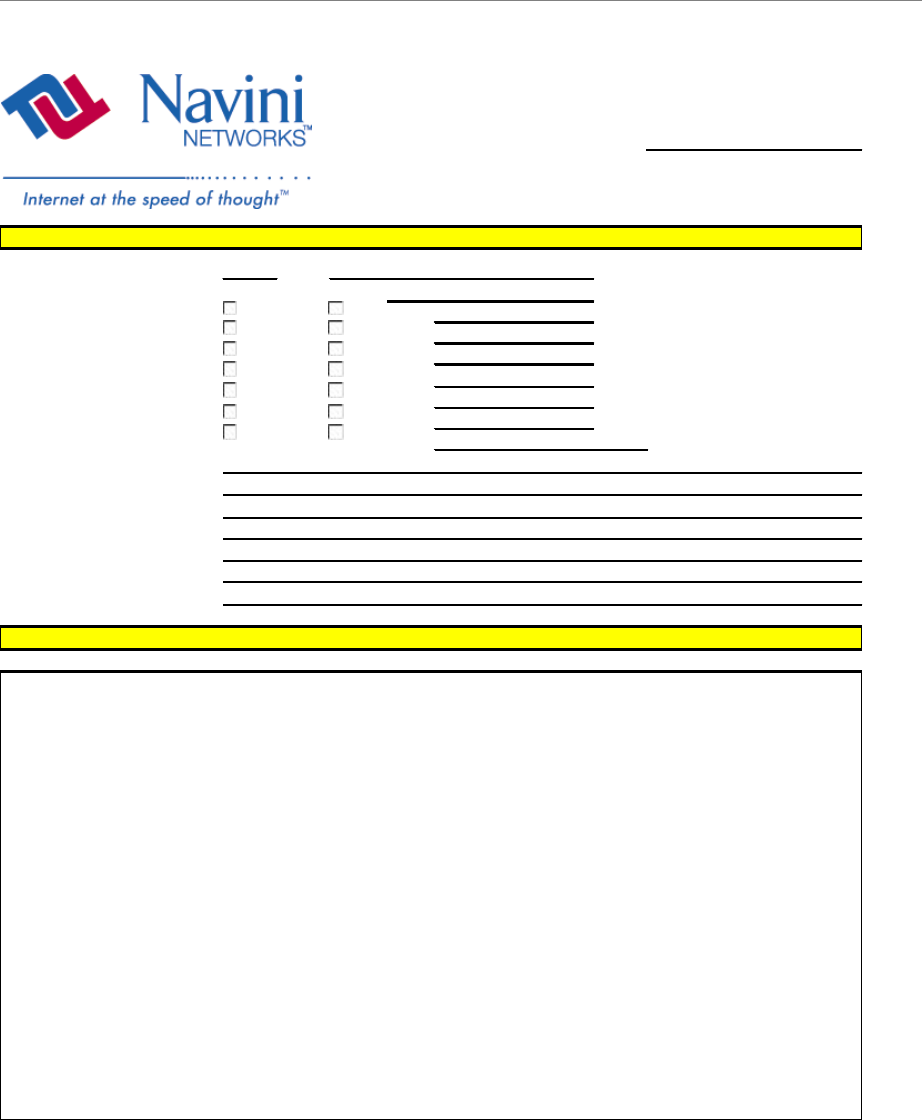

Appendix D: Site Candidate Evaluation Form

NAVINI NETWORKS

SITE EVALUATION FORM

PN - 40-00091-00

Site Name

Date

FSE

COMPANY NAME

ADDRESS

SITE OWNER

SITE CONTACT NO.

GPS COORDINATES LAT LONG

ANT TYPE (OMNI, PANEL)

ENCLOSURE TYPE (HUT, ETC) ELEV (AMSL) FEET

TOWER TYPE (SS, MP,ETC) HEIGHT (AGL) FEET

SITE ACCESS RESTRICTIONS OTHER

DRIVE TO DIRECTIONS

BTS Space Availability (3' x 3') x

Room for Expansion BTS x

Type/Size of Cabinet required FEET

110VAC, 20A Available/Distance FEET

AC Outlet Available/Distance FEET

24VDC, 60A Available/Distance FEET

Breaker(s) Required

Sub-metering Required

Ground Available/Distance FEET

Gnd Buss Bar Available/Distance FEET

Cable Entry Available

Cable Routing Distance FEET

Kind of Entry Material

Kind of Sealing Required

Site Plans Available

Cable Tray Available

Cable Hangers Required

Floor/Wall Drilling Permitted

Airconditioning Available

Telco/LAN/WAN Available

Demarc Location/Distance FEET

Room has Adequate Lighting

Room has Adequate Ventilation

Any Door Entry Restrictions DOOR DIMENSION

Enclosure Access OTHER

Crane/Heavy Eqpmt Required

SITE INFORMATION

SITE CONSTRUCTION INFORMATION

YES

NO

INDOOR

OUTDOOR

OMNI

PANEL

2.3GHZ

2.4GHZ

24HRS

8-5PM

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

Ground

Elevator

YES

NO

AC

DC

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

2.5GHZ

2.6GHZ

Ripwave Base Station I&C Guide Navini Networks, Inc.

124 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Proposed Antenna Height FEET COMMENTS

Cable Run Length to entry port FEET COMMENTS

Ant Space Available (10' spacing) OTHER

Special Bracket Required OTHER

Cable Hangers Required OTHER

Crane/Heavy Eqpmt Required OTHER

Structural Test Required OTHER

Interference Test Required OTHER

GPS Location Available CABLE RUN LENGTH IN FEET

GPS Comments / Details

Detailed Tower Description

TOWER/ANTENNA CONSTRUCTION INFORMATION

TOWER PICTURE

YES

NO

YES

NO

YES

NO

YES NO

YES NO

YES

NO

YES NO

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 125

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

SITE MAP / SKETCH

GPS ANTENNA LOCATION

Ripwave Base Station I&C Guide Navini Networks, Inc.

126 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

NORTH VIEW

NORTHEAST VIEW

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 127

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

EAST VIEW

SOUTHEAST VIEW

Ripwave Base Station I&C Guide Navini Networks, Inc.

128 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

SOUTH VIEW

SOUTHWEST VIEW

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 129

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

WEST VIEW

NORTHWEST VIEW

Ripwave Base Station I&C Guide Navini Networks, Inc.

130 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

EXISTING COMPOUND PICTURE

GROUNDING

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 131

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

INGRESS

EGRESS

Ripwave Base Station I&C Guide Navini Networks, Inc.

132 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

POWER

TELCO

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 133

October 23, 2003

NAVINI NETWORKS

SITE EVALUATION FORM

Site Name 0

Comments

Comments

SHELTER PICTURE

SHELTER LAYOUT AND DIMENSION DRAWING

Ripwave Base Station I&C Guide Navini Networks, Inc.

134 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 135

October 23, 2003

Appendix E: Interference Sweep Procedure

Before You Start

The instructions in this document assume the Field Engineer is at the Base Station site and that the

BTS and RFS have not yet been installed.

Required Equipment

You will need the following equipment to perform the Interference Sweep:

?? HP4404B Spectrum Analyzer or equivalent. An equivalent analyzer must have the following:

- Screen Save abilities

- Max-hold function

- Peak search

- Ability to operate in the required frequency range

?? Omni or Directional Antenna for the given frequency range

The directional antenna should have a gain of > 9 dBi.

?? Cavity Filter

Pass band should cover the frequency range. It must have good out-of-band rejection so the

LNA is not jammed by high power AMP, PCS, or TV signals.

?? LNA Module

Gain > 21dB, NF < 7dB, for frequency range

?? Various SMA and N-Type adapters

?? Various RF cables to connect to Antenna and to test equipment

Initial Configuration

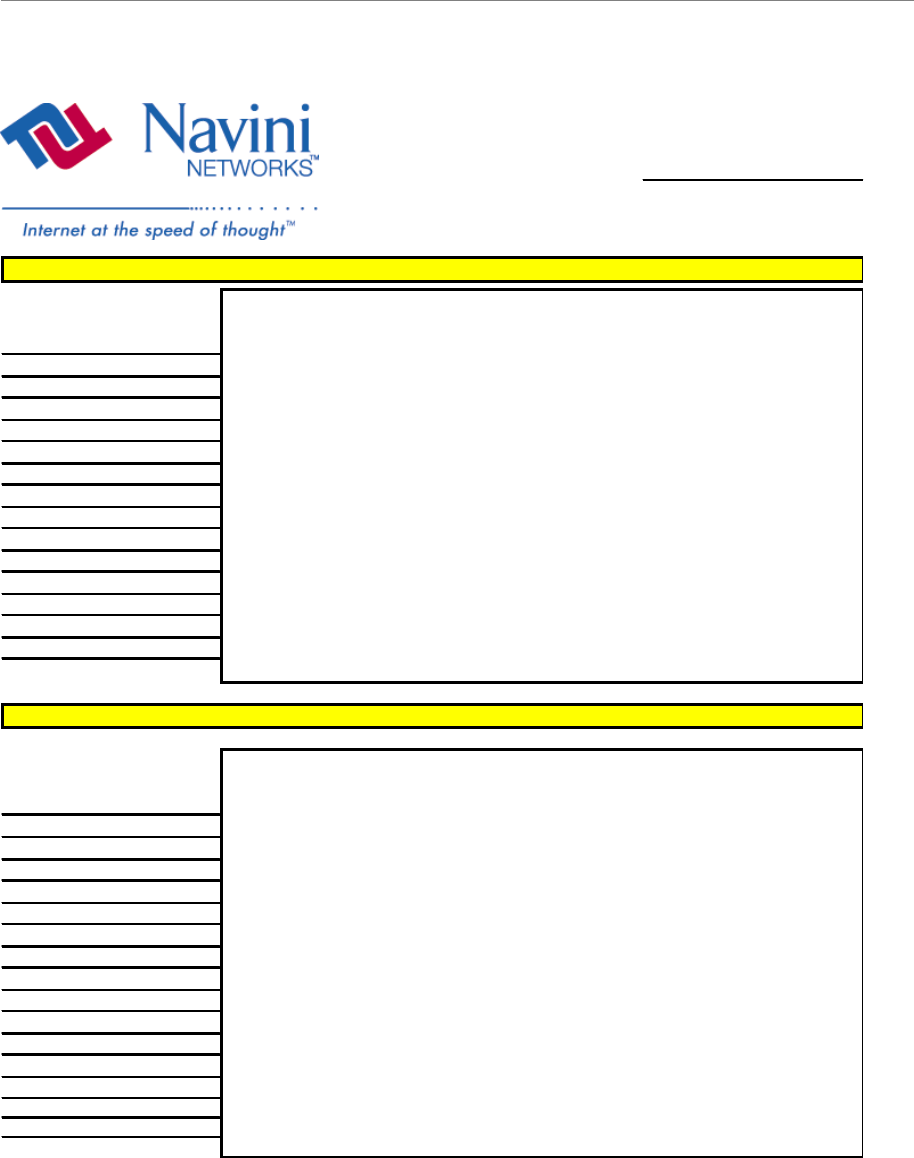

The set-up shown in Figure E1 and the information below are for the initial configuration. It gives

you a starting point for this procedure. During the later steps, this configuration will change.

Ripwave Base Station I&C Guide Navini Networks, Inc.

136 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Figure E1: Initial Configuration

Step 1. Configure test equipment as shown in Figure E1.

Step 2. Program the initial Spectrum Analyzer settings, per the following:

A. Resolution Bandwidth= 100KHz

B. Video Bandwidth = 100KHz

C. Attenuation = 0db

D. Ref level = -10db

E. Sweep time = auto

F. Detector mode = positive peak

G. Frequency = will be determined at each point during the procedure.

Step 3. Set the frequency sweep range per the following.

A. 2.4GHz = sweep for ranges 2.390GHz to 2.5GHz

B. 2.6GHz = sweep for ranges 2.596GHz to 2.644GHz

Interference Sweep Procedure

The following information applies to both Panel and Omni antennas. It guides you through the steps

to capture data required for the interference study. The number of steps varies depending on the type

of antenna you are using and the frequency band you are investigating. If you are using an omni

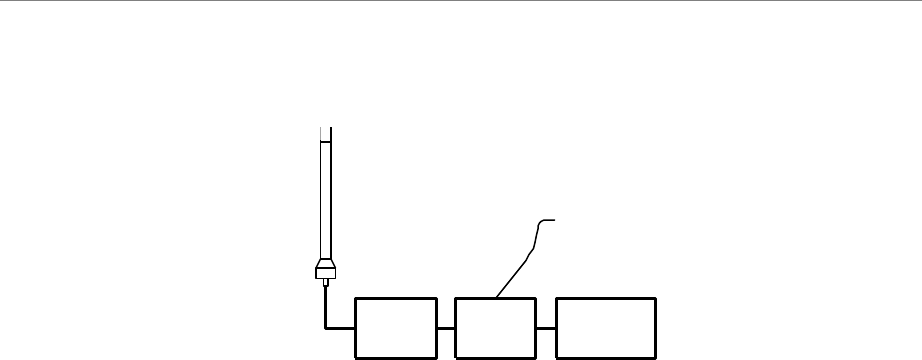

antenna to perform this procedure, only one pass is required. If a directional antenna is used, the

number of passes through the procedure is determined by the beamwidth of the antenna.

When using a directional antenna to pick up the interference, try to change the angle or downtilt to

face a potential interference source such as a tower or a more populated area. A directional antenna

is used to determine the location of the source that is generating the interference. The beamwidth of

the directional antenna determines the number of directions that you need to sweep.

For example, if the beamwidth of the directional antenna is 90 degrees, then four passes of the

procedure are necessary. Whereas, an antenna with a 30-degree beamwidth requires 12 sets of

Antenna

Spectrum

Analyzer

Cavity

Filter LNA

Module

Figure 1: Initial Configuration

DC

Powered

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 137

October 23, 2003

sweeps to cover the same 360 degree area. The smaller beamwidth requires more sweeps but gives

you greater accuracy in determining the source of the interfering signal. On each pass the directional

antenna is moved per the beamwidth. Refer to Figure E2.

With both types of antennas, try to determine the polarization of the interfering signals during each

sweep. To do this, flip the antenna 90 degrees. All measurements that are captured are with the

antenna in the vertical polarization position.

The frequency band to be investigated is determined by the range of the BTS and RFS that is

purchased by a customer. The 2.6GHz MMDS band is a licensed band, and the customer purchasing

the equipment will have a license for a given 6MHz channel. The 2.4GHz band is an unlicensed

frequency range that is open for many applications. The objective for the 2.4GHz sweeps is to find a

5MHz range that is the clearest of any interference.

Figure E2: 90 Degree Directional Sweep

The 2.6GHz sweeps are done to verify that there is not another carrier infringing on the given

licensed channel. If you are performing the sweeps for a licensed 2.6GHz channel, it will greatly

reduce the number of steps that you will need to perform. For a 2.6GHz system you only need to

look at three channels for the spectrum. You will sweep the licensed channel as well as the channels

above and below the licensed band.

For example: If you have an E3 license (2.620GHz – 2.626GHz), you will sweep E3 plus F2

(2.614GHz-2.620GHz) and F3 (2.626GHz – 2.632GHz).

90

DEGREES

90

DEGREES

90

DEGREES

90

DEGREES

TEST

ANTENNA

POSITION 1

TEST

ANTENNA

POSITION 2

TEST

ANTENNA

POSITION 3

TEST

ANTENNA

POSITION 4

Ripwave Base Station I&C Guide Navini Networks, Inc.

138 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

You will only need the Max-hold portion of the procedure for 2.6GHz systems.

Max-hold

The Max-hold portion of the procedure is to be used for both unlicensed and licensed systems.

Step 1. If using a directional antenna, check the direction of the antenna with a compass.

Record the results.

Step 2. Set the Start Frequency to 2.390GHz for a 2.4GHz system and to 2.595GHz for a

2.6GHz system.

Step 3. Set the Stop Frequency to 2.5GHz for a 2.4GHz system and to 2.645GHz for a

2.6GHz system.

Step 4. Replace the antenna with a terminator to get a noise floor level. Save a screen capture.

Step 5. Turn on the Max-hold feature and acquire the signal for two minutes. Save a screen

capture.

Step 6. Run Single Sweep two times, saving the screen captures for both sweeps. This gives a

reference for the worst case that is shown with the Max-hold in Step 5. Time can be

saved on this step if the Spectrum Analyzer is equipped with a dual trace option. Turn

Trace 2 on constant sweep and Trace 1 on Max-hold. After the Max-hold has

acquired a signal for two minutes, press the single sweep. Save the screen capture.

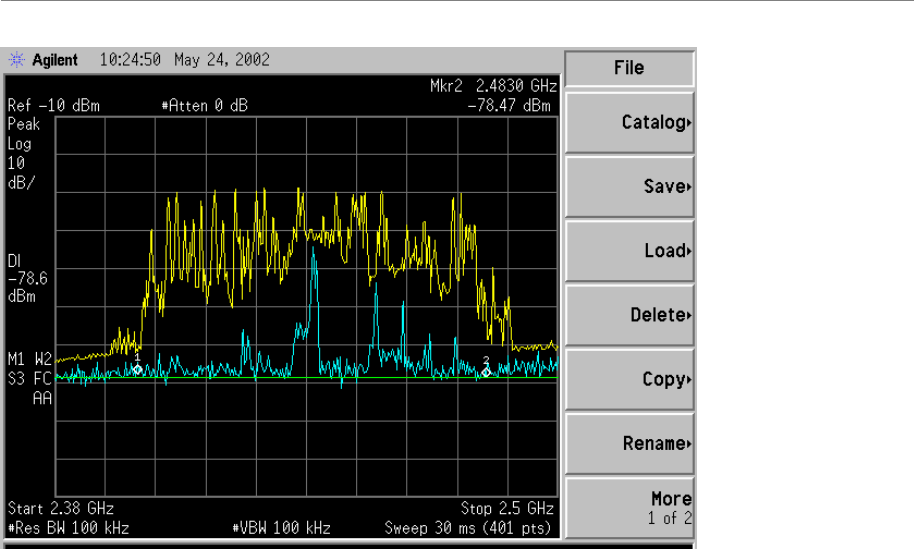

Refer to Figure E3, Max-hold Screen Capture.

Step 7. Repeat steps 5 and 6 with the following Start and Stop frequencies.

2.4GHz Band 2.6GHz Band

Start Stop Channel Start Stop

2.4GHz 2.45GHz E1 2.596GHz 2.602GHz

2.45GHz 2.5GHz F1 2.602GHz 2.608GHz

2.4GHz 2.41GHz E2 2.608GHz 2.614GHz

2.41GHz 2.42GHz F2 2.614GHz 2.62GHz

2.42GHz 2.43GHz E3 2.62GHz 2.626GHz

2.43GHz 2.44GHz F3 2.626GHz 2.632GHz

2.44GHz 2.45GHz E4 2.632GHz 2.638GHz

2.45GHz 2.46GHz F4 2.638GHz 2.644GHz

2.46GHz 2.47GHz

2.47GHz 2.48GHz

2.48GHz 2.49GHz

Figure E3: Max-hold Screen Capture

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 139

October 23, 2003

Time Domain

The Time Domain portion of the procedure is for unlicensed systems only.

Step 1. Set the Center Frequency to 2.4025GHz. Set the Resolution Bandwidth to 5 MHz.

Step 2. Set the Video Bandwidth to 1MHz.

Step 3. Set the Sweep Time to 40 ms.

Step 4. Set the Span to 0 Hz.

Step 5. Replace the antenna with a terminator to get a noise floor level. Save a screen capture.

Step 6. Set the display line to the noise floor level. The display line needs to stay on for all of

the following sweeps. This display line is used for a reference point and should be set

with the LNA powered on.

Step 7. Run the Single Sweep approximately 50 times and determine how often the

interference occurs. Save a screen capture of one worst case and one typical. See

Figure E4, Time Domain Screen Capture.

Step 8. Set the Sweep Time to 400 ms, and repeat Step 7.

Step 9. Repeat Steps 7 and 8 for an offset of 5MHz up to 24875MHz for 2.4 systems.

Ripwave Base Station I&C Guide Navini Networks, Inc.

140 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

2.4GHz Band

Center Frequency

2.4075GHz

2.4125GHz

2.4175GHz

2.4225GHz

2.4275GHz

2.4325GHz

Up to 2.4875GHz

Step 10. If a directional antenna is used, repeat the Max-hold and Time Domain steps for each

direction.

Figure E4: Time Domain Screen Capture

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 141

October 23, 2003

Appendix F: Interference Sweep Tool

Overview

The Navini 2.4 GHz frequency Interference Sweep Test tool is used by an Installation &

Commissioning Technician or Field Engineer to sweep and collect data concerning RF conditions at

a specific site. The location is typically a site that has been identified as a potentially good candidate

for a Base Station installation.

The test tool manages the RF sweep and interference level conditions, with post-analysis performed

by RF Engineering personnel using simulation models. The results of the analysis are not a

guarantee of optimal operating conditions for the Ripwave system. The objective is to identify and

eliminate sites that might pose high potential problems in order to prioritize a given list of sites for

Base Station deployment.

Installation

Equipment

1. Navini Survey Test Box

2. 12 pin Control Cable

3. Laptop Computer

4. Power Box With Attached Ethernet Cable

5. Power Cable for the Power Box

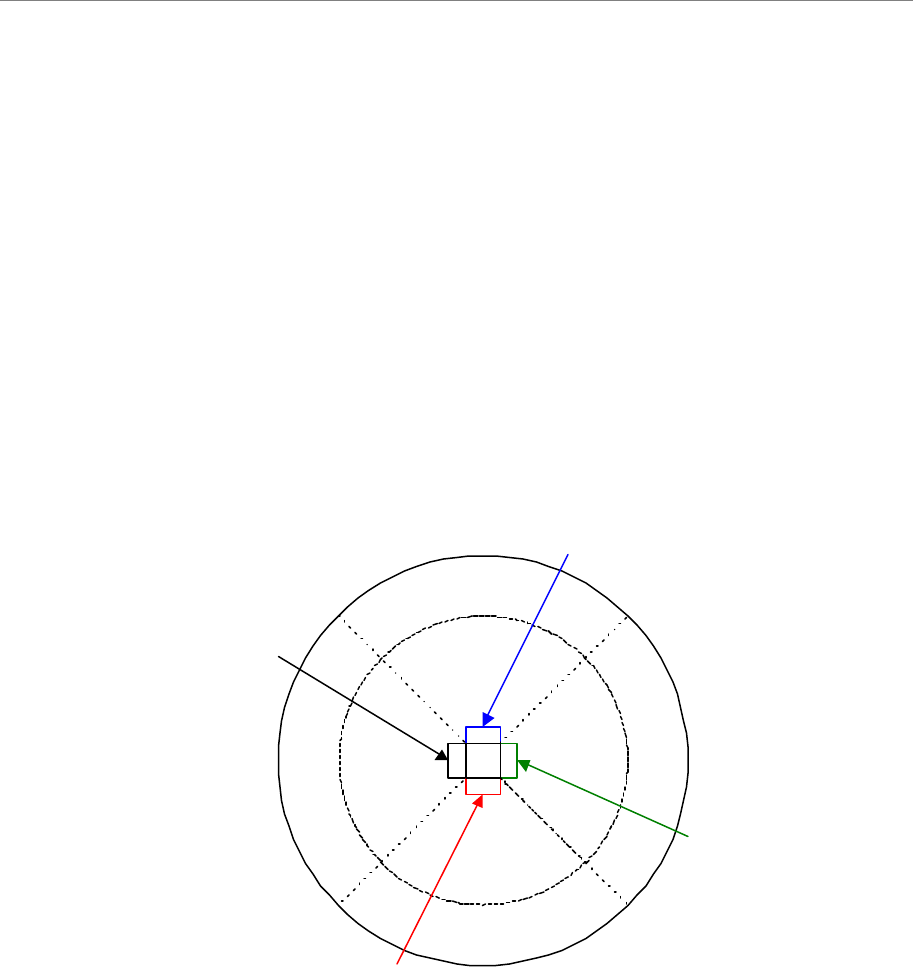

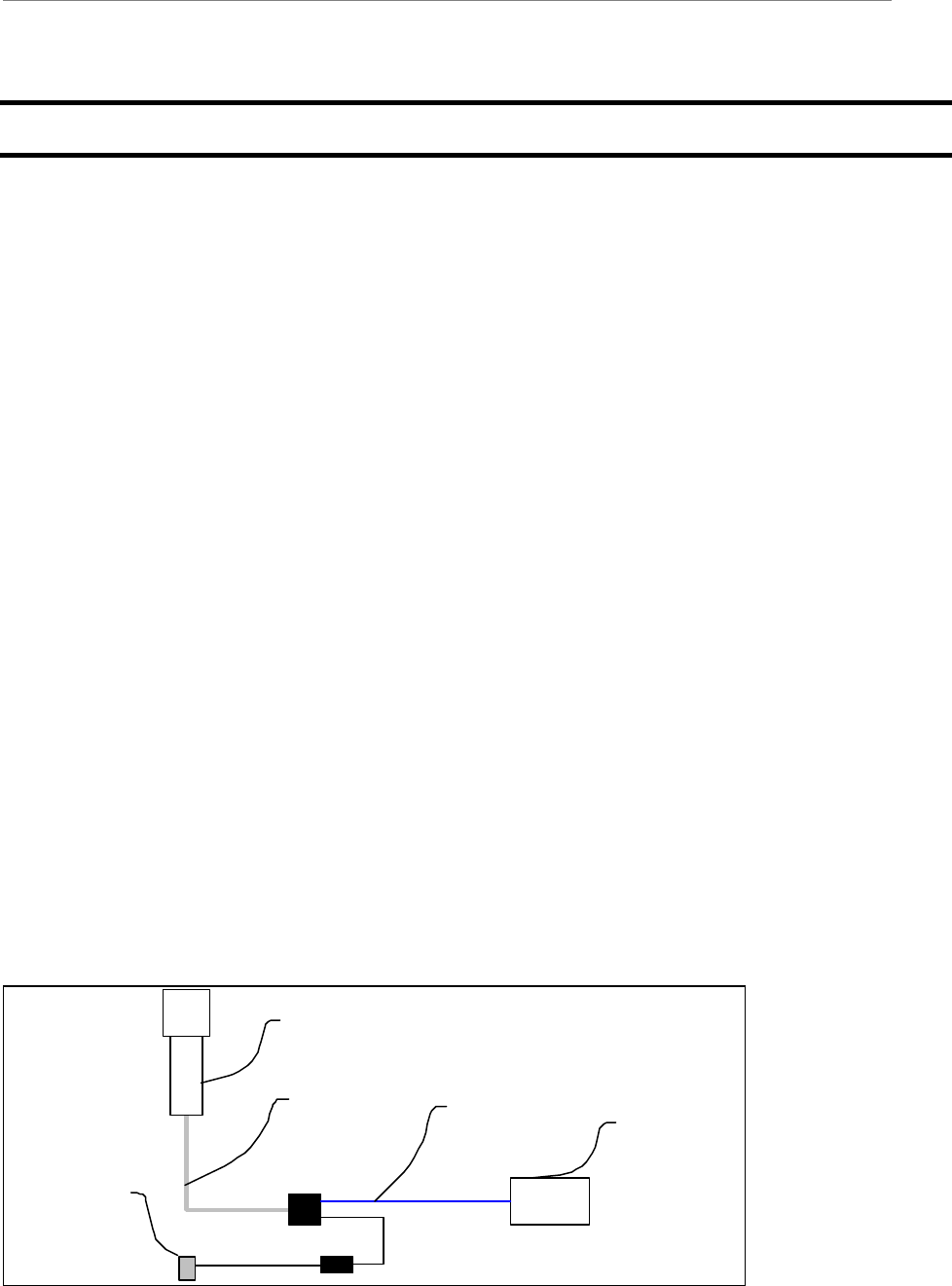

Figure F1 is a block diagram showing the requirements to install the equipment. Figure F2 provides

an example of the laptop and cable configuration.

Figure F1: Block Diagram

Navini Test Box

Laptop Computer

AC outlet

Control Cable Ethernet Cable

Ripwave Base Station I&C Guide Navini Networks, Inc.

142 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

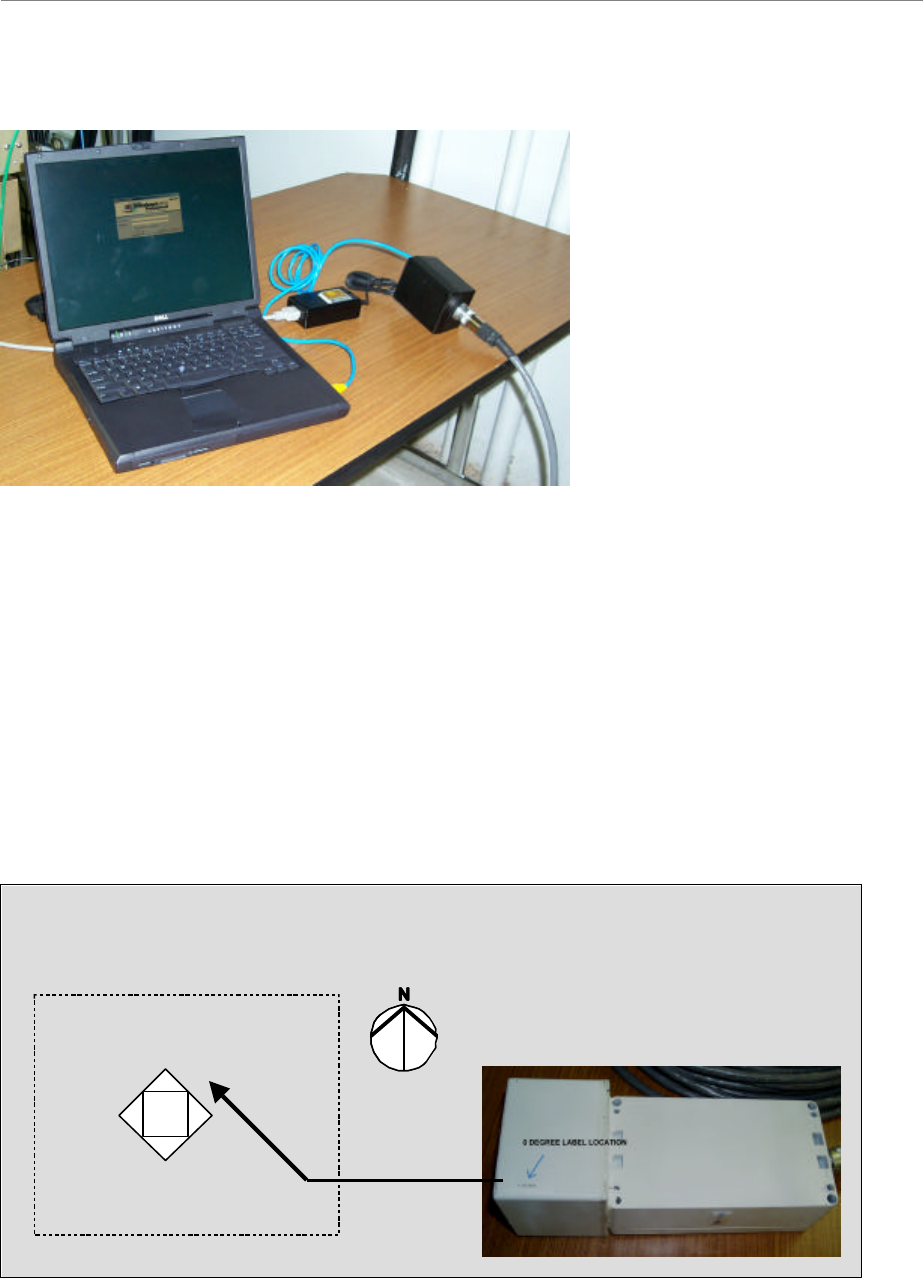

Figure F2: Laptop & Cable Configuration

Mounting

The Navini Test Box should be installed in the location where the RFS will be installed, or as close

as possible. This will give the most accurate representation of the interference at the site. On the

upper portion of the test box there are three labels indicating 0, 120, and 240 degrees (Figure F3).

These are the antennas that are inside the test box. The label indicating 0 degrees should be pointed

as close to north as possible. Connect the Control Cable from the Navini Test Box to the Control

Box. The Control Box has a power connector, a circular control cable connector, and a blue

Ethernet cable on it. The Ethernet cable will be connected to your laptop.

Figure F3: Test & Control Box Setup

0 degrees

120 degrees

240 degrees

Top down view of

Navini Test Box

Control Box

0 degrees

120 degrees

240 degrees

Top down view of

Navini Test Box

Control Box

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 143

October 23, 2003

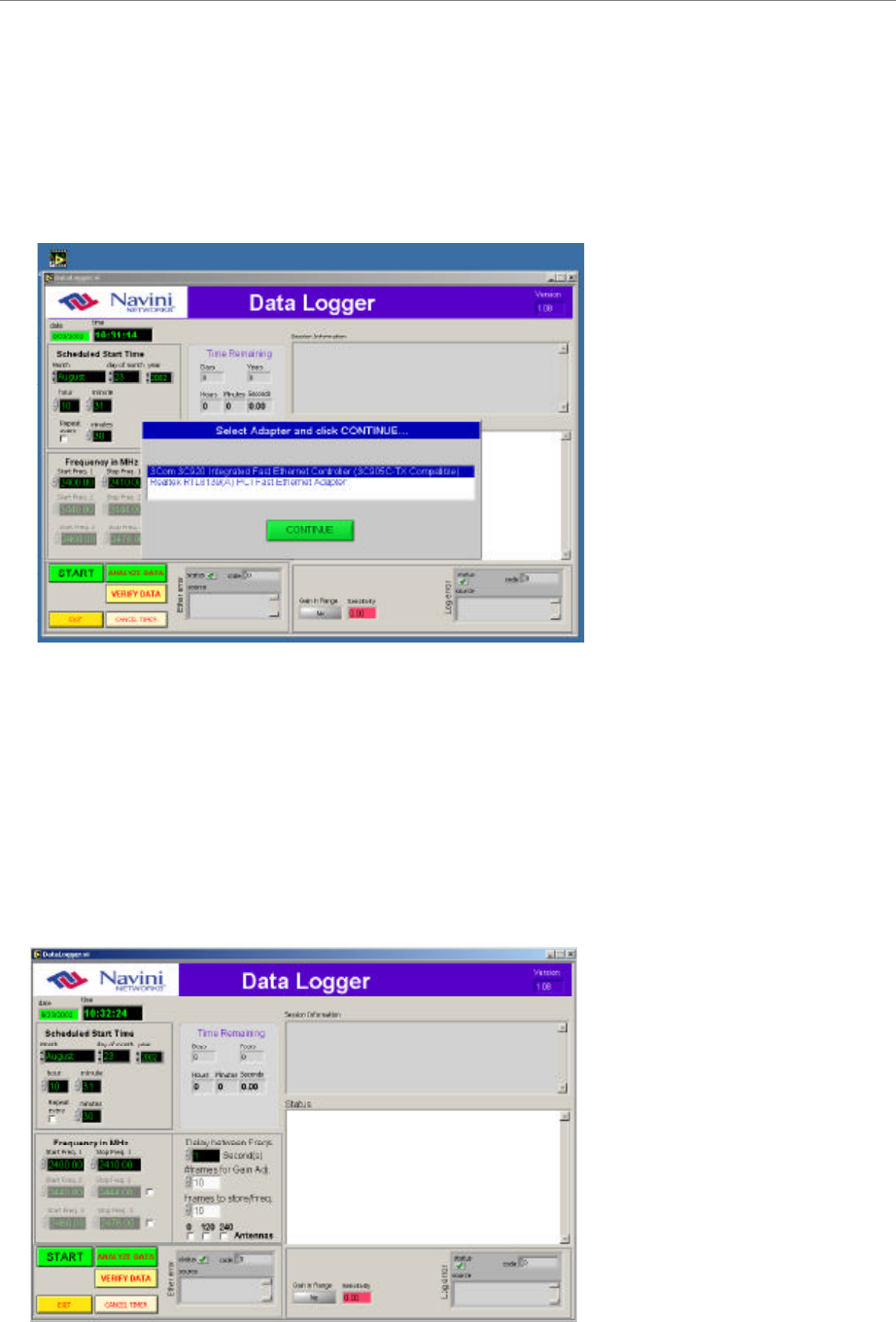

Figure F4 shows a sample of the mounting requirements for the installation.

Figure F4: Mounting Requirements

Using the Site Survey Tool

Recommended Settings

1. Interval Setting

Provided by Navini Networks RF planning group

2. Frequency Selection

2.400 to 2.476 GHz approved ISM operating frequency

3. Number of Frames for Gain Adjustment

Provided by Navini Networks RF planning group; site specific

4. Number of Stored Frames

Provided by Navini Networks RF planning group; site specific

Ripwave Base Station I&C Guide Navini Networks, Inc.

144 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Procedure

Step 1. Open the application by selecting the Data Logger icon. Figure F5 shows the icon in the

background.

Figure F5: Data Logger

Step 2. Select the desired Ethernet adapter in the pop-up window.

Step 3. Starting in the upper left corner of the program screen, set the date and time for the

application to start its measurement interval. If the date and time set are earlier than the

current time, logging will begin immediately.

Step 4. If the measurement needs to be repetitive, determine the interval between measurements

by selecting the repeat box and entering the time interval (Figure F6).

Figure F6: Measurement Interval

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 145

October 23, 2003

Step 5. Select the frequencies to be measured.

a. There are 3 frequency band selections. By default two are not available until selected

by clicking on the white checkboxes to the right of each.

b. If you select more than one band, it is best if you put in some delay between each

band’s measurements, as mentioned in Step 6 below.

Step 6. If more than one frequency band has been selected, choose the delay to be used between

each band’s measurements. You can use the scroll bar or just type in the interval.

Step 7. Select the number of frames for Gain Adjust. This allows the system to calculate the

Modem’s receiver sensitivity.

Step 8. Select the number of frames to be stored for analysis. The same number will be captured

for each frequency band if more than one is selected.

Step 9. Ensure antenna orientation is selected properly. It takes about 1 second to log one frame

of data. Therefore:

Elapsed time = #antSelected ? [(number_of_gain_adj Frames) ? n + (Freq_Range/2) ?

#of_framesToLog + (Freq_Range/2) ? delayBetweenFreqs]

Where n is the number of gain adjustment loops. Up to 10 are possible if the received

signal varies to a great extent in amplitude from frame to frame.

Step 10. Select the Start button.

Step 11. Enter in the desired Site Name in the pop-up window, and press Enter to start the

measurements.

Step 12. To stop the measurement, select the Abort button.

Step 13. PC and Test operation should be validated every 3-4 hours for working order.

To Verify the Data

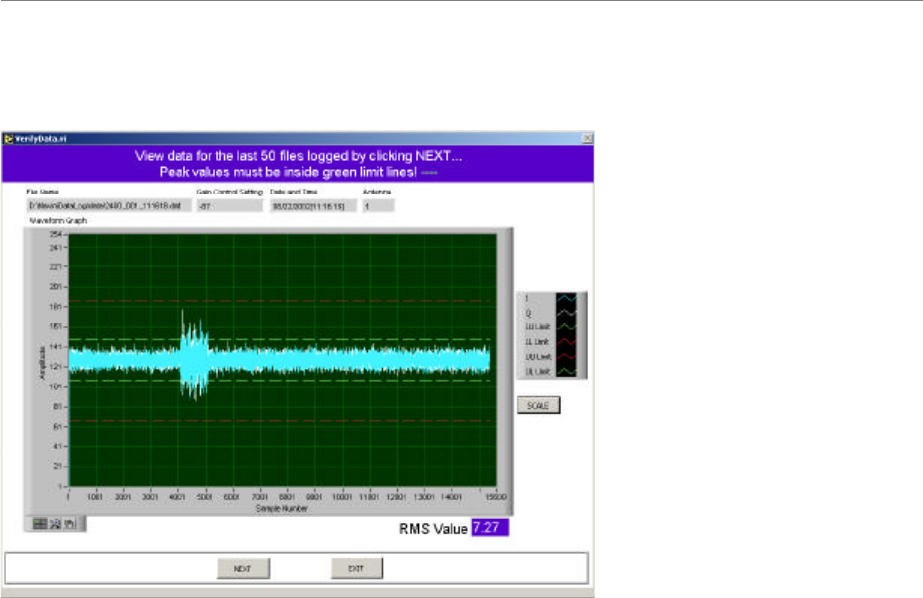

Step 1. Click the Verify Data button. The screen shown in Figure F7 appears. The last 50

data files logged can be viewed with this screen. Click on NEXT to view the next file.

Ripwave Base Station I&C Guide Navini Networks, Inc.

146 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Figure F7: Verify Data

Analysis of Data

Not available on this release.

FTP Instructions

Step 1. Launch FTP Pro.

Step 2. Select the file, “Rfsweep”.

Step 3. The FTP Password is provided by Navini in a separate document.

Step 4. To transfer the file, locate the Navinidatalog folder on the “C” drive of the laptop.

Step 5. Select all files in the data folder via FTP browser, then, send the files.

Step 6. Once the file transfer is complete, delete the data folder and rename the “gain.adj” file for

the next test sequence. Create a new “gain_adj” folder under the NaviniDataLog folder.

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 147

October 23, 2003

Appendix G: BTS Specifications

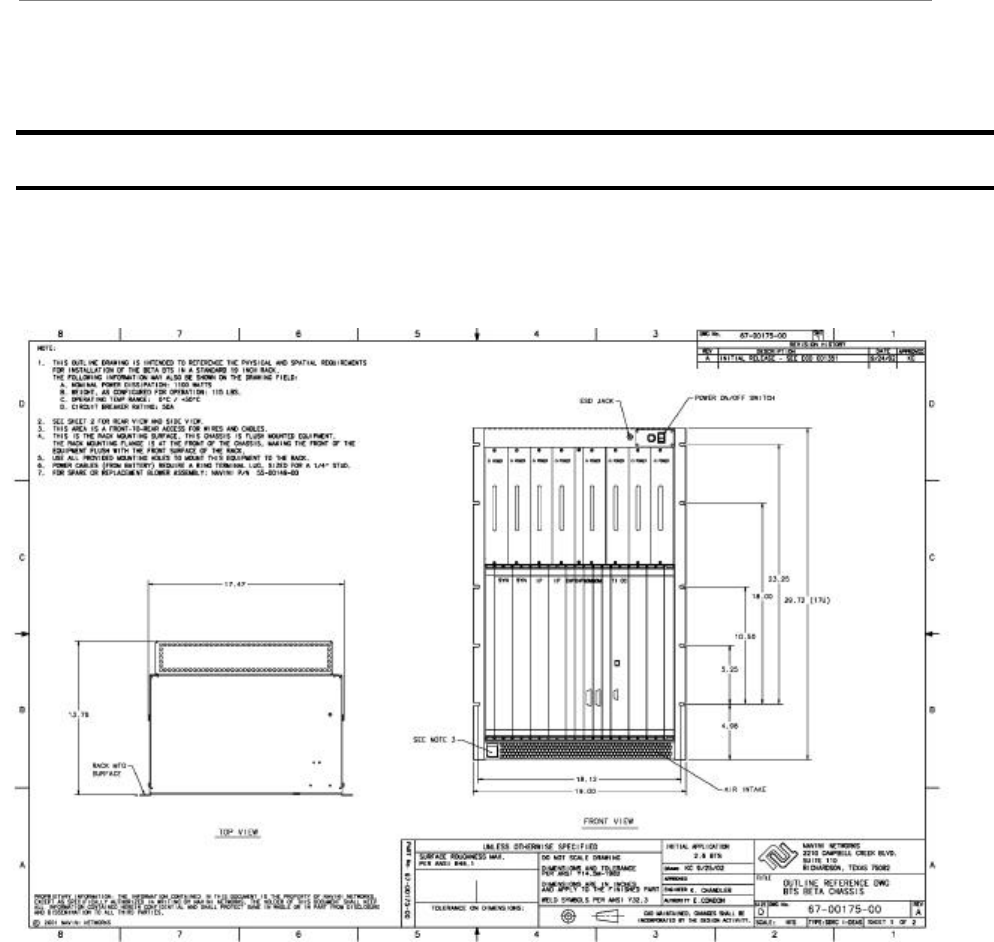

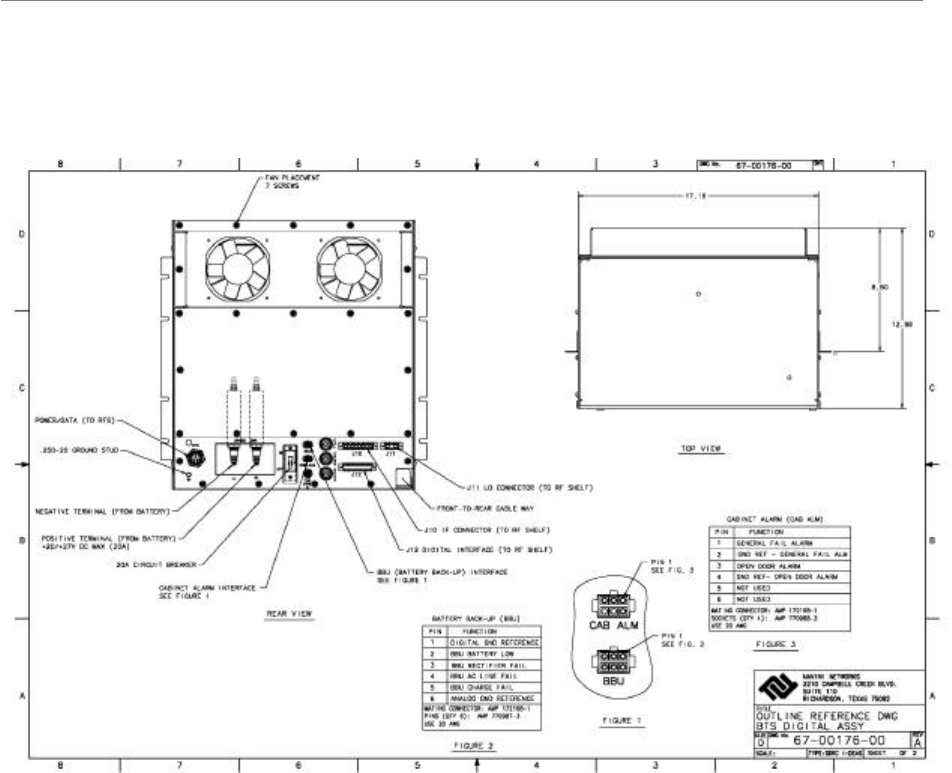

Figure G1: Combo Chassis (Front)

Ripwave Base Station I&C Guide Navini Networks, Inc.

148 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

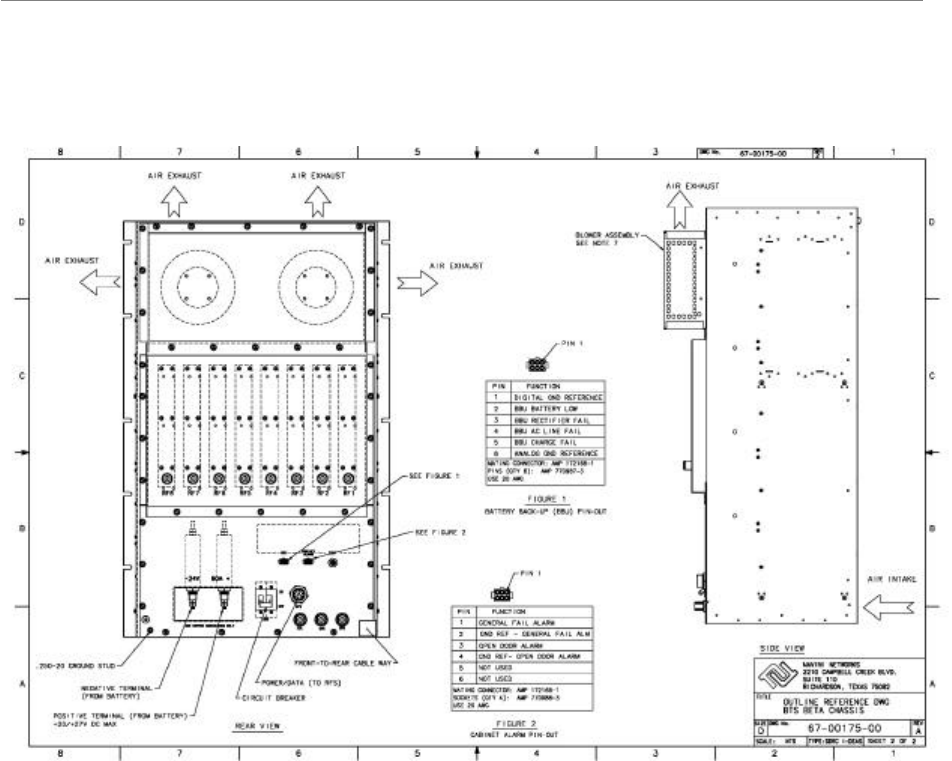

Figure G2: Combo Chassis (Back)

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 149

October 23, 2003

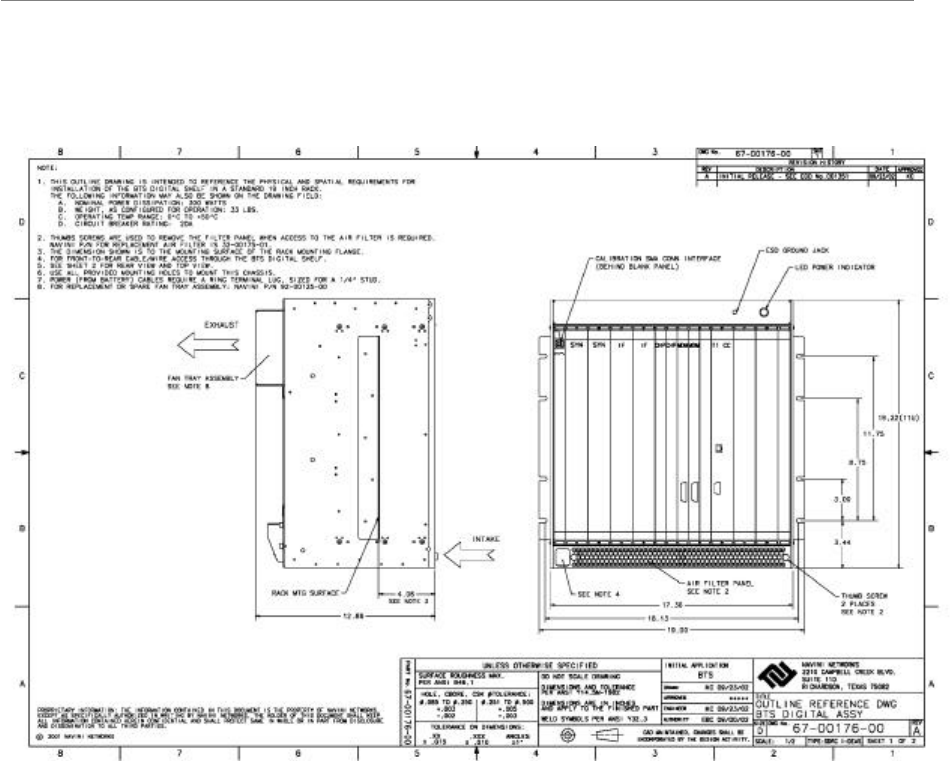

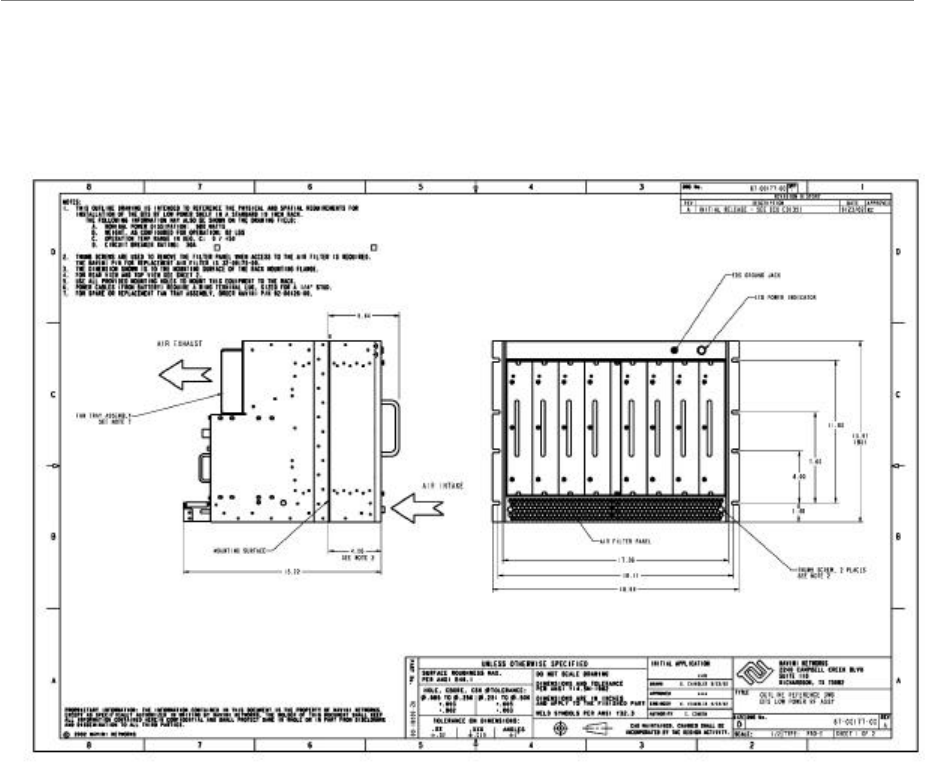

Figure G3: Split Digital Chassis (Front)

Ripwave Base Station I&C Guide Navini Networks, Inc.

150 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Figure G4: Split Digital Chassis (Back)

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 151

October 23, 2003

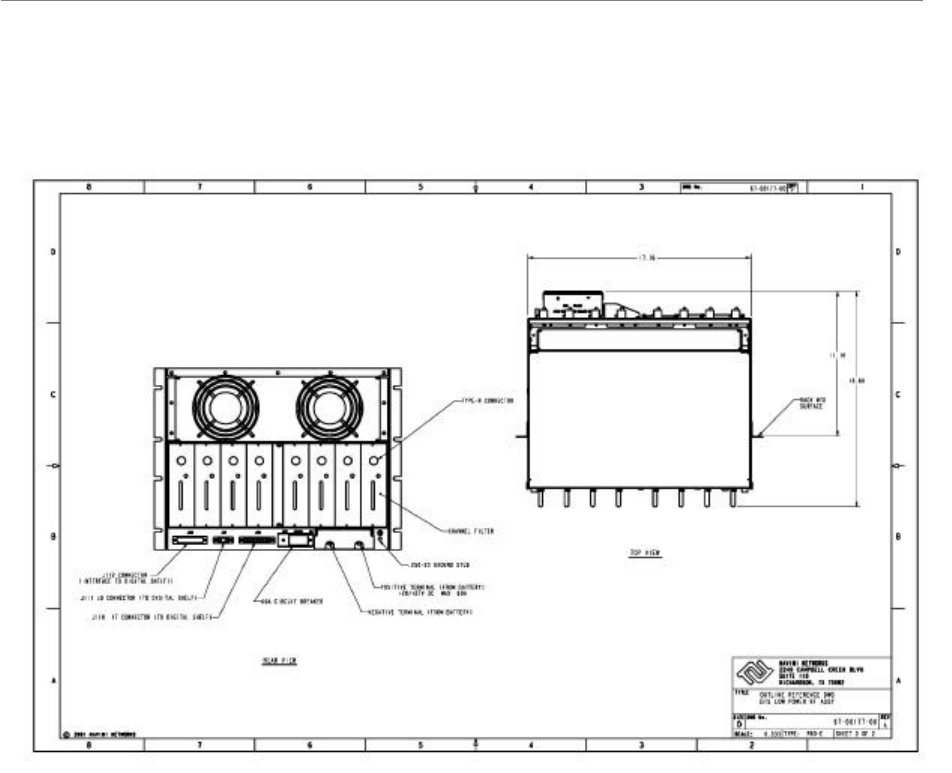

Figure G5: Split RF Chassis (Front)

Ripwave Base Station I&C Guide Navini Networks, Inc.

152 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Figure G6: Split RF Chassis (Back)

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 153

October 23, 2003

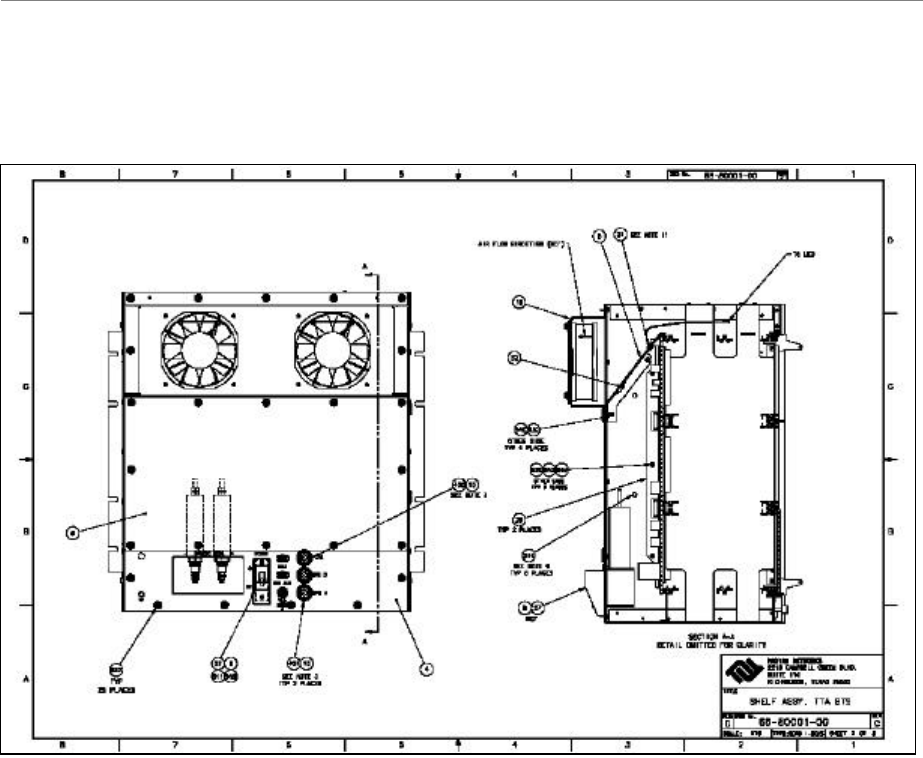

Figure G7: TTA Digital Chassis (Front)

Ripwave Base Station I&C Guide Navini Networks, Inc.

154 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Figure G8: TTA Digital Chassis (Back)

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 155

October 23, 2003

Appendix H: RFS Data Sheets

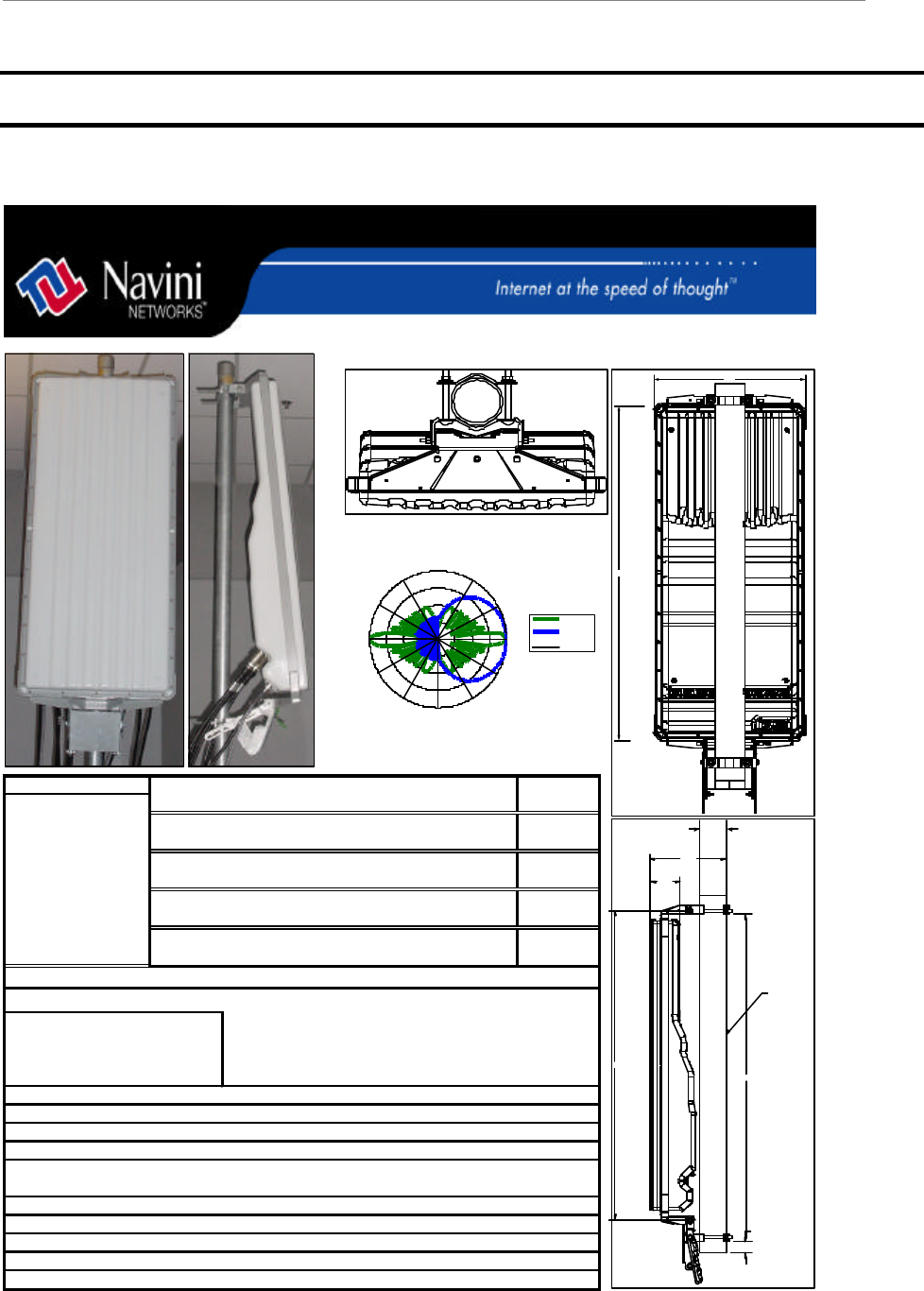

Figure H1: Panel

NAVINI PART NUMBER: 95-23000-00

95-23100-00

95-23000-05

95-23100-05

95-00043-05

95-10043-05

95-25000-00

95-25100-00

95-00005-05

95-10005-05

DESCRIPTION

Frequency Range

Polarization

Antenna Gain

Horizontal HPBW

Vertical HPBW

Connector Type's

Lateral Thrust at 100 MPH (161 KM/HR) w/o ice

Mounting Configurations

Electrical Downtilt

Mechanical Downtilt/Uptilt

Weight

2.4GHz w/o LNAs

2.5GHz ABCD with LNAs

2.5GHz ABCD w/o LNAs

220 LB. Lateral Load

To Pipe Mount - 2 3/4" TO 3" OD

2.4GHz range = 2.4GHz through 2.473GHz

2.5GHz range = 2.500GHz through 2.596GHz

2.6GHz EFGH range = 2.596GHz through 2.686GHz

9 Female "N" Type

17-17.5 dBi for 120 Degree Sectored

6 Degrees

2.3GHz Low Band

Vertical

2.6GHz EFGH with LNAs

2.6GHz EFGH w/o LNAs

2.3GHz High Band

2.3GHz Low Band w/o LNAs

2.3GHz High Band w/o LNAs

2.3GHz low band range = 2.305GHz Through 2.320GHz

2.3GHz high band = 2.345GHz through 2.360GHz

2.4GHz with LNAs

81 LB. Including Bracket Mount no pipe

Broadband Sectored Panel Antenna

Navini RFS

6 Degrees

0 - 10 Degrees Mechanical

1 - 12 Pin Female Circular

130 Degrees

Panel RFS Antenna Pattern

-20.00

-15.00

-10.00

-5.00

0.00

Vertical

Horizontal

Scale

57.5"

2"

12.6"

54.5"

5"

GALVANIZED

ANTENNA

MOUNTING

PIPE

4.5 OD pipe

sch 40 pipe

53.4"

22.9"

Ripwave Base Station I&C Guide Navini Networks, Inc.

156 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

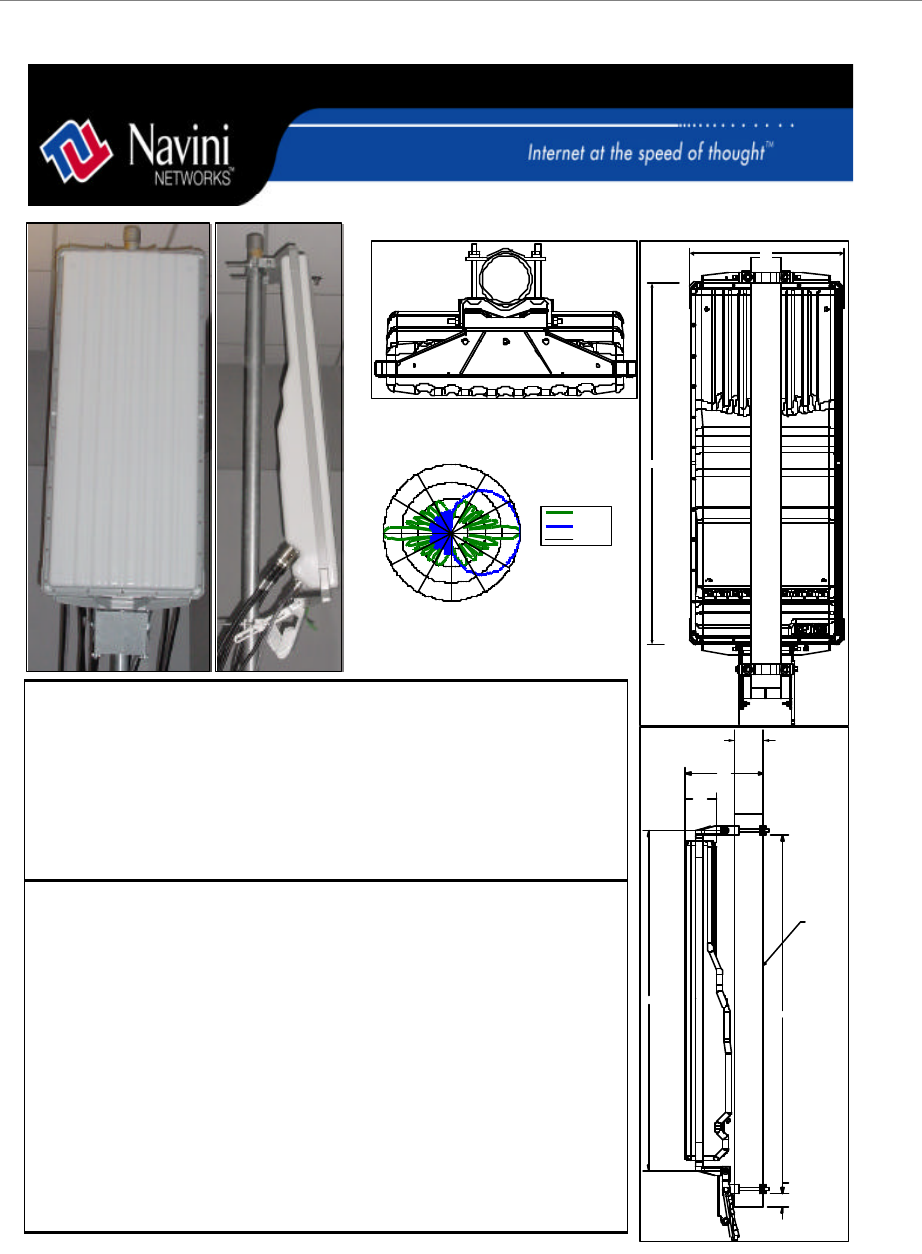

Figure H2: Panel TTA

NAVINI PART NUMBER: 95-00043-10

DESCRIPTION

Frequency Range

Polarization

Antenna Gain

Horizontal HPBW

Vertical HPBW

Connector Type's

DC Power Dissipation

Lateral Thrust at 100 MPH (161 KM/HR) w/o ice

Mounting Configurations

Electrical Downtilt

Mechanical Downtilt/Uptilt

Weight

2.4GHz TTA RFS

220 LB. Lateral Load

To Pipe Mount - 2 3/4" TO 3" OD

2.4GHz range = 2.4GHz through 2.483GHz

9 Female "N" Type

17-17.5 dBi for 120 Degree Sectored

6 Degrees

Vertical

81 LB. Including Bracket Mount no pipe

Broadband Sectored Panel Antenna

Navini RFS

6 Degrees

0 - 10 Degrees Mechanical

80 Watts

130 Degrees

Panel RFS Antenna Pattern

-20.00

-15.00

-10.00

-5.00

0.00

Vertical

Horizontal

Scale

57.5"

2"

12.6"

54.5"

5"

GALVANIZED

ANTENNA

MOUNTING

PIPE

4.5 OD pipe

sch 40 pipe

53.4"

22.9"

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 157

October 23, 2003

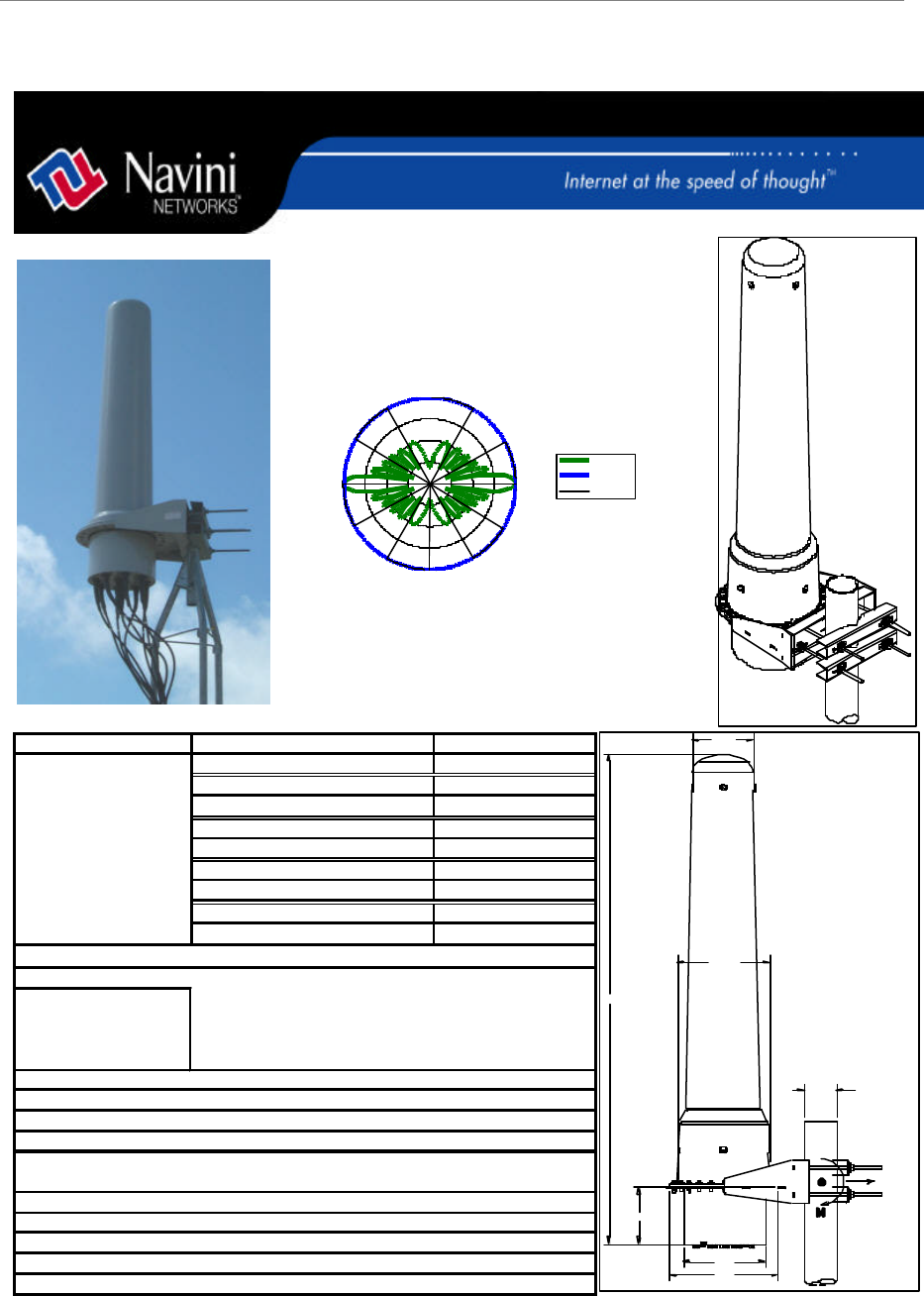

Figure H3: Omni

P/N 44-00038-01 Rev A v1.0 Feb.14, 2003

NAVINI PART NUMBERS:

note: * 02 or 12 are for degree of

downtilt also available are 04 and

14

** xx is the degree of downtilt

02 or 04.

Frequency Range

Polarization

Antenna Gain

Horizontal HPBW

Vertical HPBW

Connector Type's

Lateral Thrust at 100 MPH (161 KM/HR) w/o ice

Mounting Configurations To Pipe Mount

Electrical Downtilt

Mechanical Downtilt

Weight

2.3GHz- high band without LNAs

95-23008-12*

95-23108-02*

95-23108-12*

95-23008-02*

2.3GHz- low band with LNAs

2.3GHz- high band with LNAs

2.3GHz- low band without LNAs

95-24008-xx**

2.4GHz- with LNAs

2.4GHz- without LNAs

2.5GHz- with LNAs

95-24108-xx**

N/A

73 lbs. Including mount

2 and 4 Degree

11.5dBi

Omni

132 LB. Lateral Load

6 Degrees

9 Female "N" Type

1 - 12 Pin Female Circular

DESCRIPTION

Broadband Omnidirectional Antenna

Navini RFS

95-25008-xx**

95-25108-xx**

95-26008-xx**

95-26108-xx**

2.5GHz- without LNAs

2.6GHz- EFGH with LNAs

2.6GHz- EFGH without LNAs

2.6GHz EFGH range = 2.596GHz through 2.686GHz

Vertical

2.3GHz low band range = 2.305GHz Through 2.320GHz

2.3GHz high band = 2.345GHz through 2.360GHz

2.4GHz range = 2.4GHz through 2.473GHz

2.5GHz range = 2.500GHz through 2.596GHz

Omni RFS Antenna Pattern

-20.00

-15.00

-10.00

-5.00

0.00

Vertical

Horizontal

Scale

13.057"

73.5"

11.7"

15.5"

8.5"

8.9"

R

Ø3.0-Ø4.5 OD PIPE

FR

Ripwave Base Station I&C Guide Navini Networks, Inc.

158 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

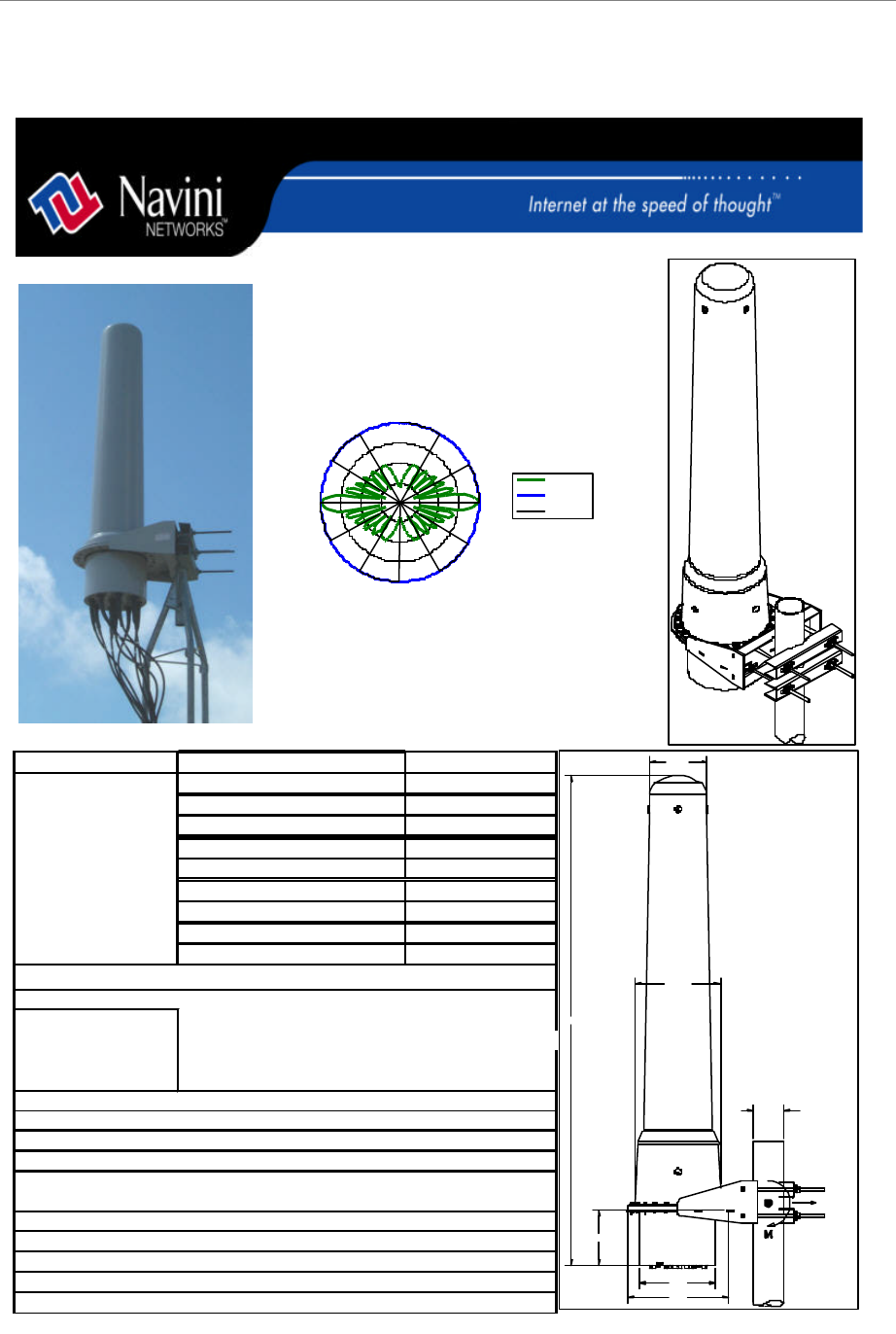

Figure H4: Omni TTA

NAVINI PART NUMBERS:

Frequency Range

Polarization

Antenna Gain

Horizontal HPBW

Vertical HPBW

Connector Type's

DC Power Dissipation

Lateral Thrust at 100 MPH (161 KM/HR) w/o ice

Mounting Configurations To Pipe Mount

Electrical Downtilt

Mechanical Downtilt

Weight

Vertical

2.4GHz range = 2.4GHz through 2.483GHz

DESCRIPTION

Broadband Omnidirectional Antenna

Navini RFS

N/A

73 lbs. Including mount

2 and 4 Degree

11.5dBi

Omni

132 LB. Lateral Load

6 Degrees

9 Female "N" Type

80 Watts

95-24018-02

2.4GHz TTA RFS, 2 degree downtilt

Omni RFS Antenna Pattern

-20.00

-15.00

-10.00

-5.00

0.00

Vertical

Horizontal

Scale

13.057"

73.5"

11.7"

15.5"

8.5"

8.9"

R

Ø3.0-Ø4.5 OD PIPE

FR

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 159

October 23, 2003

Appendix I: BTS Outdoor Enclosure Manufacturers

General

Navini Networks does not manufacture external cabinets for the Ripwave BTS. The following lists

two manufacturers who are positioned to provide external cabinets for the Navini system. Inclusion

of the manufacturers on this list does not represent an endorsement of the manufacturer or its

products by Navini Networks.

Manufacturers List

Purcell Systems

22924 E. Appleway Avenue

Liberty Lake, WA 99019

509 755-0341

Steve Busby

Http://www.purcellsystems.com/

Hendry Telephone Products

55 Castillan Drive

Santa Barbara, CA 93117

805 571-8287

Phil Skeen

Ripwave Base Station I&C Guide Navini Networks, Inc.

160 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 161

October 23, 2003

Appendix J: Rectifier/BBU Suppliers

General

This section includes contact information for two rectifier/BBU suppliers. Inclusion of a supplier on

this list does not represent an endorsement of the supplier or its products.

Suppliers List

Valere Power Systems

651 N. Plano Road, Suite 421

Richardson, TX 75081

469 330-9100

Matt McManus

Argus DC Power

Argus Regional Sales Manager

Addison, IL

630 530-5006

Richard Meyer

http://www.argusdcpower.com/

Regulatory

Reference Chapter 1, Page 8 “Regulatory Information” requirements.

Ripwave Base Station I&C Guide Navini Networks, Inc.

162 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 163

October 23, 2003

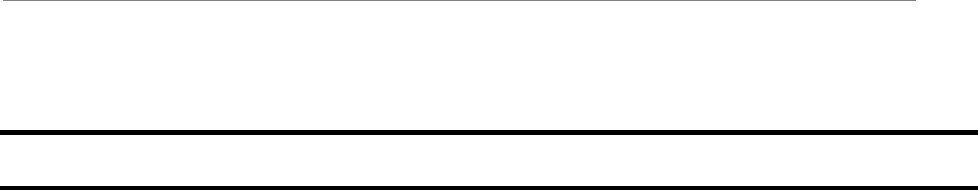

Appendix K: Sample Base Station Drawing

Figure K1: Sample Base Station Drawing

NAVINI NETWORKS

BASE STATION LAYOUT

WATER TOWER OPTION

PANEL ANTENNA

PSX-ME

SURGE

PROTECTOR

GROUND

BAR

RF CABLES

ANTENNA

BRACKET

GPS

CABLE

LADDER

CABLE

ENTRY

GROUND

BAR

ETHERNET

/ TELCO

SHELTER / HUT

OPTION 1

INDOOR BTS

OVERHEAD CABLE LADDER

24VDC

@ 60A

CABINET

GND

PSX

GROUND BAR

NAVINI

BTS

24VDC

@ 60A

CABINET

GND

PSX

GROUND BAR

NAVINI

BTS

ETHERNET

/ TELCO

OPTION

2

INDOOR BTS

CABLE RUN / CABLE LADDER

OPTION 3

CABLE RUN / INTERNAL RUN

OPTION 4

LIGHTNING

ROD

RF CABLES

CORE TO INSIDE

OF TOWER

PANEL

ANTENNA

BTS Opt 1

Indoor

PANEL

ANTENNA

BTS Opt 2

Indoor

PSX-ME

SURGE

PROTECTOR

PANEL LOCATION

OPTION 5

PANEL LOCATION

OPTION 6

Ripwave Base Station I&C Guide Navini Networks, Inc.

164 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

NOTE

1.CABLE BUNDLE CONSIST OF 9 RF CABLES AND 1 POWER/DATA CABLE

2.RF CABLE TYPE TO BE DETERMINED BASED ON RUN LENGTH AND DB

LOSS/FT

3.CABLE HANGERS TO BE SPECIFIED/RECOMMENDED BY TOWER CREW

4.ANTENNA BRACKET TO BE SUPPLIED BY CUSTOMER AS RECOMMENDED BY

TOWER CREW

5.BTS REQUIRES 24VDC @ 60A.

6.PSX-ME SURGE PROTECTORS TO BE INSTALLED IN-LINE BETWEEN RF

CABLE AND ANTENNA

7.PSX SURGE PROTECTOR TO BE MOUNTED ON GROUND BAR CLOSE TO BTS

CABINET/CHASSIS

8.ETHERNET/TELCO BACKHAUL TO BE PROVIDED BY CUSTOMER

9.ALL INSTALLED EQUIPMENT/MATERIALS MUST BE PROPERLY GROUNDED

10.OPTION 1 IS FOR AN INDOOR BTS INSTALL, OPTION 2 IS FOR

OUTDOOR BTS

CUSTOMER

SITE NAME

LOCATION

1PANEL LOCATION OPTION 5=DOME TOP 6=SIDE

2ANTENNA BRACKET TYPE

3PSX-ME SURGE PROTECTOR PCS

4ANTENNA AZIMUTH

5

6DEGREES

7FEET

8

ANTENNA HEIGHT

ANTENNA DOWNTILT

TOWER JUMPER LENGTH

TOWER JUMPER CABLE TYPE

9

10 FEET

11 PCS

12

13 PCS

14 GROUNDING CABLE LENGTH FEET

15 PCS

16 PCS

WEATHERPROOFING KIT

GROUNDING KIT

HOISTING GRIP

MAIN FEEDER TYPE

MAIN FEEDER LENGTH

GROUND BUSS BAR

CABLE HANGER TYPE

17

18 GPS CABLE LENGTH FEET

19 GPS CABLE TYPE

GPS MOUNT

20 LOCATION OPTION 1=SHELTER 2=INSIDE TOWER

21 CABLE RUN OPTION 3=EXTERNAL 4=INTERNAL

22 JUMPER CABLE LENGTH FEET

23 JUMPER CABLE TYPE

24 PSX SURGE PROTECTOR PCS

25 GPS SURGE PROTECTOR PCS

26 ALT GROUND BUSS BAR PCS

27 24VDC/60A POWER SUPPLY

28 INDOOR RACK/CABINET

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 165

October 23, 2003

Appendix L: Antenna Power & Cable Selection

Overview

This section provides formulas and data that are necessary inputs for determining the right cable to be

measured, cut, and installed. There are 3 types of cables that are part of the Base Station installation: antenna

cables, calibration (cal) cable, and data/power cable.

The antenna cables are the eight cables that carry amplified RF signals. They run between the RF/PA cards

and the 8 antenna elements. The calibration (cal) cable is a single RF coaxial cable that provides an RF

feedback path for calibrating the system. It runs between the backplane of the digital shelf and the RFS. The

data/power cable may or may not be a separate cable from the cal cable. It is possible to use different types of

cable with different loss factors for the antenna cables and cal cable. The formulas presented in this section

call for either an antenna cable loss or a cal cable loss. Most applications deploy the same cable type for both

the antenna and cal cables.

To determine the type of cable and acceptable loss of that cable for a site, the operating transmit and receive

range must be known. This is commonly referred to as the maximum transmit output power and the receiver

sensitivity range. The operating transmit power and receive range should have been identified during the site

survey, or they may be based on regulatory compliance.

Determining the cable type and acceptable loss for a site are typically driven by two goals: (1) Which is the

least expensive cable; and (2) Which has the higher (normally) loss. Whether or not the goals are achieved is

determined by the output power. For example, the maximum transmit output power for a 2.6 Base Station

might be given as +30dBm, or 1 Watt, to the antenna. An example of receiver sensitivity for a 2.6 system

would be given as – 80 to –90 dBm.

In addition to cable power loss, other types of loss have to be factored - for example, the calibration board.

The calibration board is part of the RFS that samples the energy being transmitted from or received by the 8

antenna elements and combines that energy which is used when performing a calibration on the Base Station.

This loss, plus cable loss and other types of loss in the equipment are called out in the following procedure.

Procedure

Read and follow the 7 steps/formulas below, in the order shown, to determine the resulting PA/RFS output

power and desired transmit and receive calibration range for the type of Base Station you will be installing.

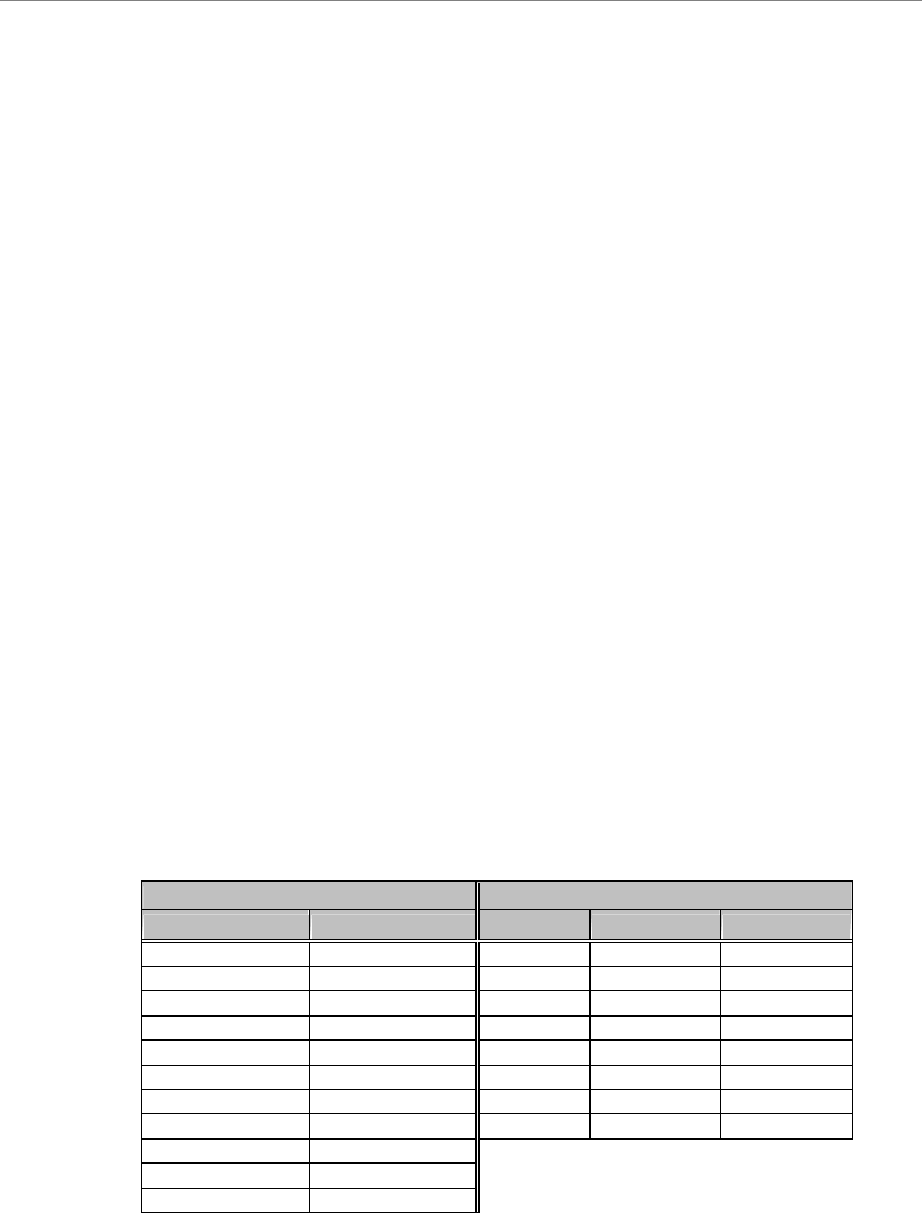

Refer to Tables L1 and L2 to complete the steps. Table L1 provides Base Station operating parameters based

on system type (2.3, 2.4, etc.), as well as other variables. Table L2 provides cable attenuation data. Before you

begin, read through the steps/formulas, notes, and Table L1 in detail. Refer to the column letters at the top of

Table L1 to locate the appropriate values requested in some of the formulas. Note that step/formula 1 contains

a sub-procedure for determining antenna cable loss using Table L2.

Ripwave Base Station I&C Guide Navini Networks, Inc.

166 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Determine the maximum capable BTS output power to the antenna.

= [(PA Output to Meet FCC) or (to Meet SNR)] – BTS Loss – RFS Loss – BTS Antenna Cable Loss*

[Column A or B]1 – [Column E]2 – [Column F or G] – [Calculated* or Measured]

?? BTS Antenna Cable loss < 18 dB for ACTIVE RFS configurations

?? BTS Antenna Cable loss < 8 dB for PASSIVE RFS configurations

Change the EMS settings accordingly.

*Sub-procedure: Calculate BTS antenna cable loss, referring to Table 8.

= [[Distance (length in ft) 100 ft] x Attenuation value/cable type] + 0.6 for 6 connectors/3 cables

Determine the maximum BTS output power that can be calibrated.

= Max Synth Input + Cal Cable Loss + Min Cal Board Loss3 + Backplane Loss4

[Column K] + [Calculated or Measured] + [Note 3] + [Default of 5.0 in EMS or Measured]

Determine the actual** max BTS output power available to the antenna.

= The lesser of the two values of Step/Formula 1 and Step/Formula 2 (aka, the “floor”)

** Actual is what you can calibrate the BTS at.

Determine the minimum BTS output power that can be calibrated .

= Min Synth Input + Cal Cable Loss + Max Cal Board Loss3 + Backplane Loss4

[Column J] + [Calculated or Measured] + [Note 3] + [Default of 5.0 in EMS or Measured]

Determine the actual** maximum EIRP.

= Step/Formula 3 + Antenna Gain. The antenna gain is affected by the type of antenna (omni, panel, 2.3,

2.4, etc.) and refers to the values in the RFS Configuration Script that accompanied the antenna from

Manufacturing.

**Actual is what you can calibrate the BTS at.

Determine the minimum BTS RX input power that can be calibrated.

= Min Synth Output - Cal Cable Loss - Min Cal Board Loss3 - Backplane Loss4

[Column H] - [Calculated or Measured] - [Note 3] - [Default of 5.0 in EMS or Measured]

Determine the maximum BTS RX input power that can be calibrated.

= Max Synth Output - Cal Cable Loss -Max Cal Board Loss3 - Backplane Loss4

[Column I] - [Calculated or Measured] - [Note 3] - [Default of 5.0 in EMS or Measured]

Step/Formula

1

Step/Formula

2

Step/Formula

4

Step/Formul

a

3

Step/Formula

5

.

.

.

.

Step/Formula

6

Step/Formula

7

Antenna

Cable

Selection

Cal

Cable

Selection

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 167

October 23, 2003

NOTES

1This note pertains to Step/Formula 1: For PA_Output_Power, if in the U.S. use Column A. If outside the U.S., as a

precaution contact Navini Technical Support (Engineering) for sign-off. The value input cannot be more than the

value shown in Column B.

2This note pertains to Step/Formula 1: BTS_Loss is either (a) loss with a filter - i.e., if operating in the U.S. or other

market that requires a filter, or (b) loss with a bypass cable. The first number (+1) is the correct value if a standard

filter is used. The second number (0.4) is the correct value if a bypass cable is used. In Column D, for a 2.3 GHz

system the values are the same for both the 8-carrier and the 10-carrier systems.

3Min loss in Cal Board is 27 dB. Max loss in Cal Board is 31 dB.

4In the EMS the backplane loss will show 5.0 as default. Actual measured loss will be indicated on the back of the

chassis.

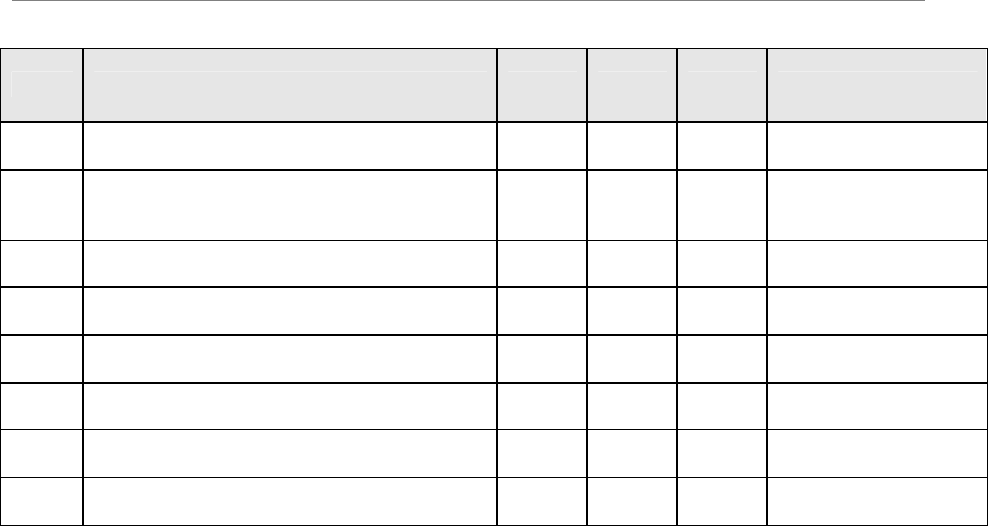

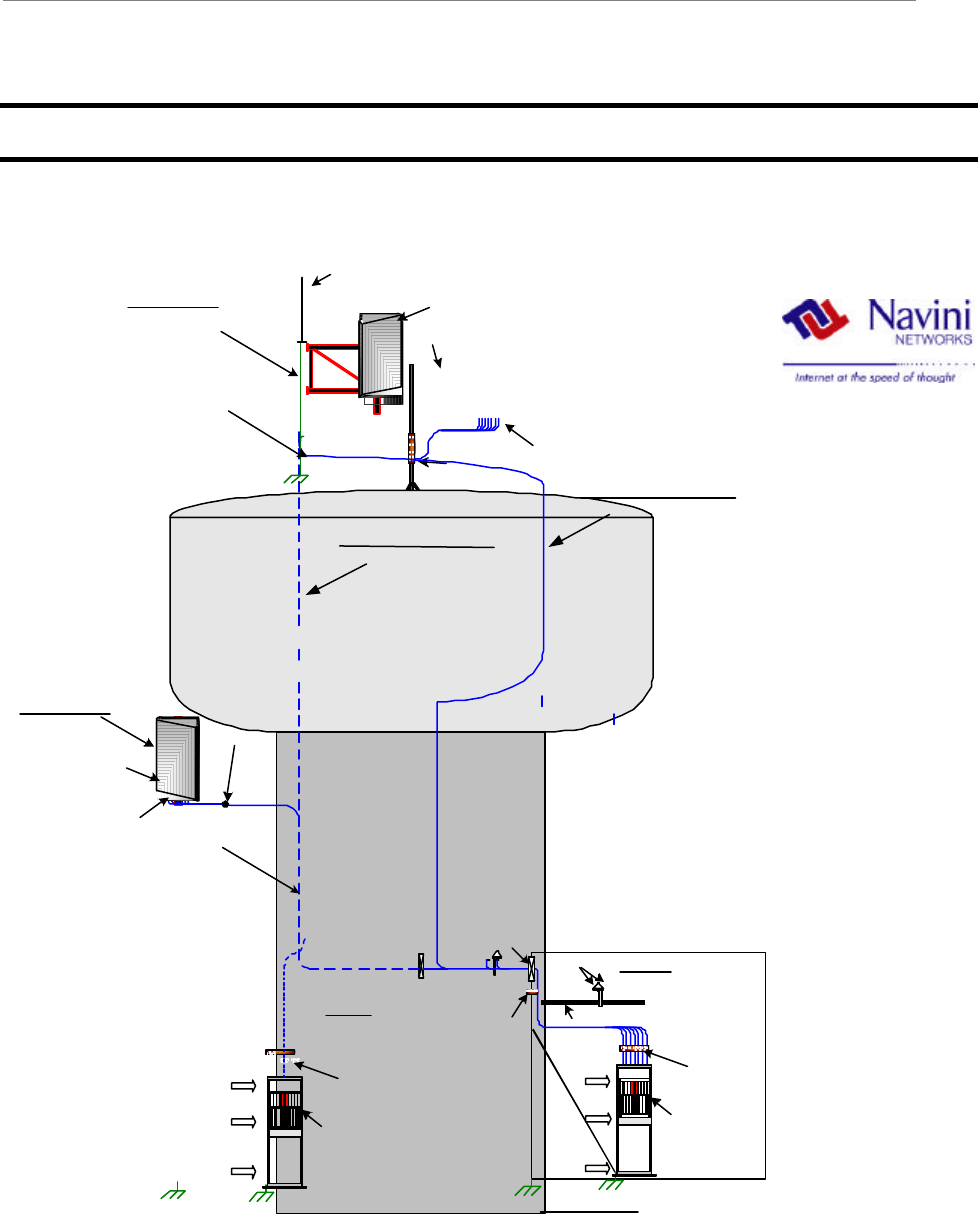

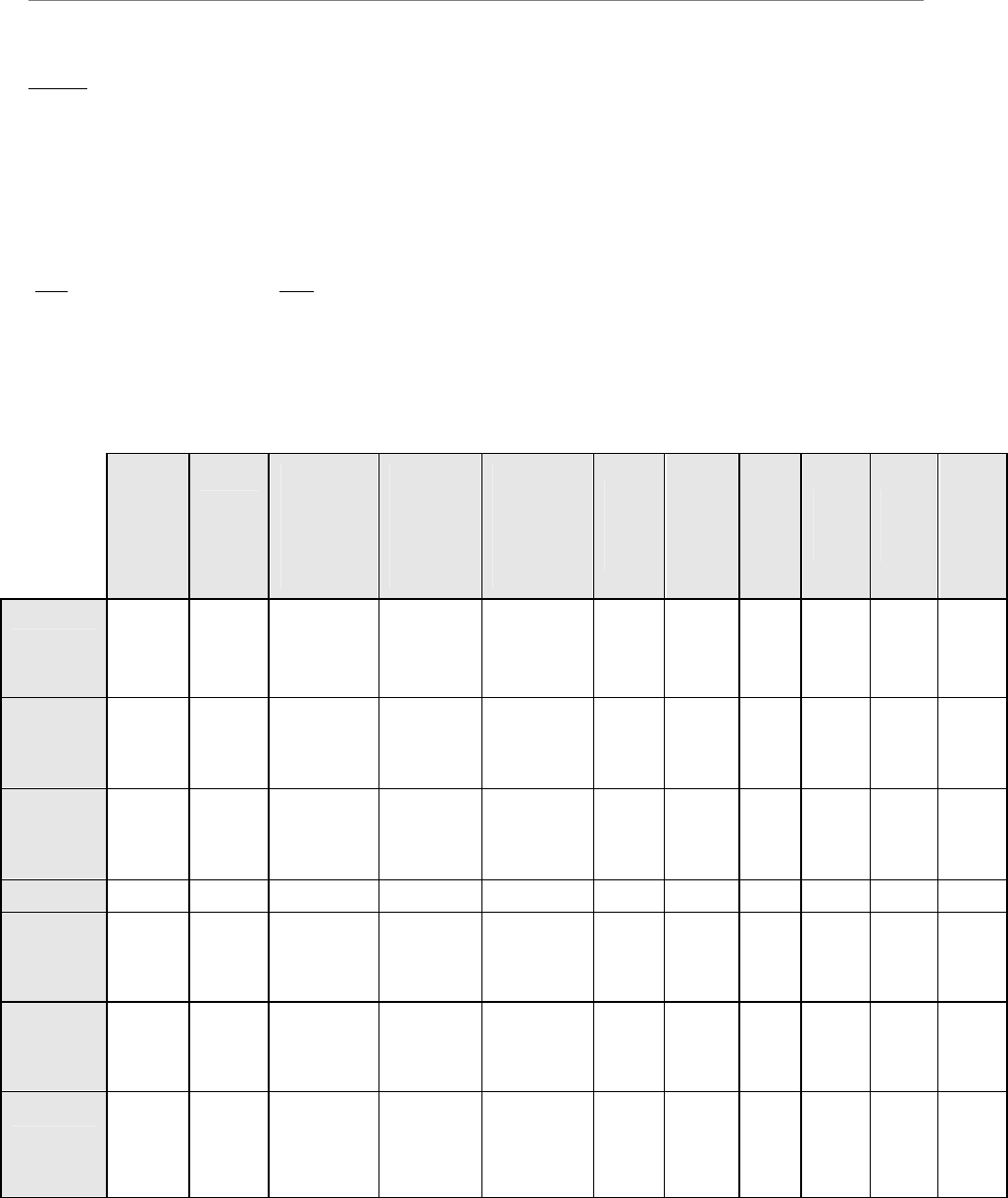

Table 7: Transmitter Operating Parameters

A B C D E F G H I J K

PA Max

Output

Power to

Meet

FCC

Limits

(dBm)

PA Max

Output

Power

(dBm)

PA Min

Output Power

Before

Damage

Level or Auto

Shutdown*

(dBm)

Max

Antenna

Terminal

Power to

Meet FCC

Limits

(dBm)

BTS Loss

With

Standard

Filter /

Bypass

Cable**

(dB)

Active

RFS

Loss

Type

(dB)

Passive

RFS

Loss

Type**

* (dB)

Synth

Min

Outpu

t

(dBm)

Synth

Max

Output

(dBm)

Synth

Min

Input

(dBm)

Synth

Max

Input

(dBm)

2.3

(6 carrier) +38 +40 +42 +30

1 / 0.4

Block Filter

has 1.0 dB

max insertion

loss

3.2 1.7 -60 -32 -23 +0

2.3

(8 carrier) +38 +40 +42 +30

1 / 0.4

Block Filter

has 1.0 dB

max insertion

loss

3.2 1.7 -60 -32 -23 +0

2.3

(10 carrier) +37 +40 +42 +30

1 / 0.4

Block Filter

has 1.0 dB

max insertion

loss

3.2 1.7 -60 -32 -23 +0

2.4 (combo) +37 +37 +42 +17.5 0.4 Bypass 3.2 1.7 -50 -20 -35 -10

2.5 +39 +41 +42 Limited by

Cable Loss

1.0 / 0.4

Channel Filter

has 1.0 +/- 0.2

dB insertion

loss

3.2 1.7 -60 -32 -23 +0

2.6

(EFGH

Split) +39 +41 +42 Limited by

Cable Loss

1.0 / 0.4

Channel Filter

has 1.0 +/- 0.2

dB insertion

loss

3.2 1.7 -60 -32 -23 +0

2.6

(EF Combo) +37 +41 +42 Limited by

Cable Loss

1.8 / 0.4

Channel Filter

has 1.8 +/- 0.2

dB including

cable to

backplane

3.2 1.7 -60 -30 -20 +0

* The lowest value at which 2.3, 2.5, and 2.6 EFGH PAs will shut down automatically. There is no auto shutdown for 2.4 and 2.6 EF combo systems.

** The value at which the bypass does not meet FCC limits.

***Passive configurations of BTS affect system Noise figure. For passive systems other than 2.4, consult SYSTEMS ENGINEERING.

Ripwave Base Station I&C Guide Navini Networks, Inc.

168 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

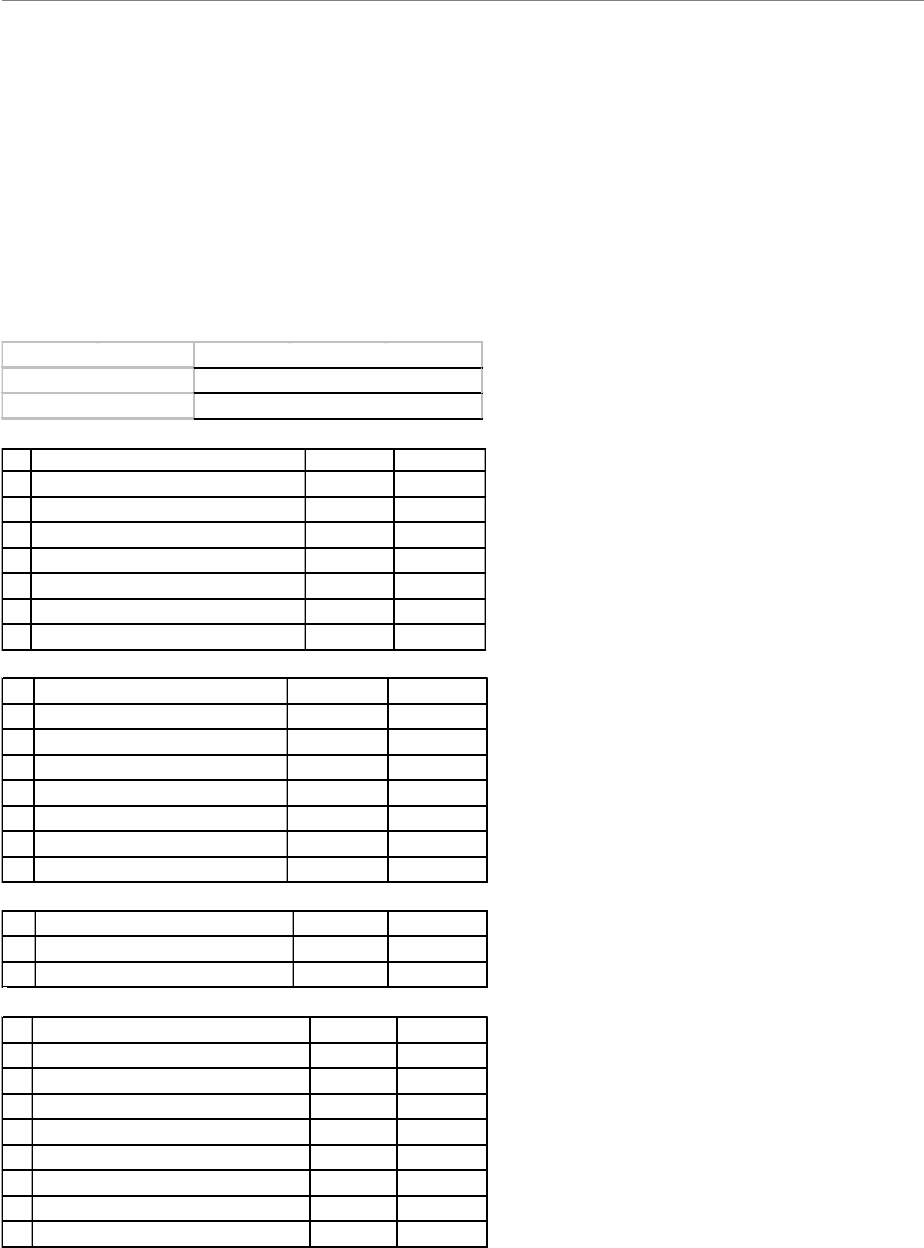

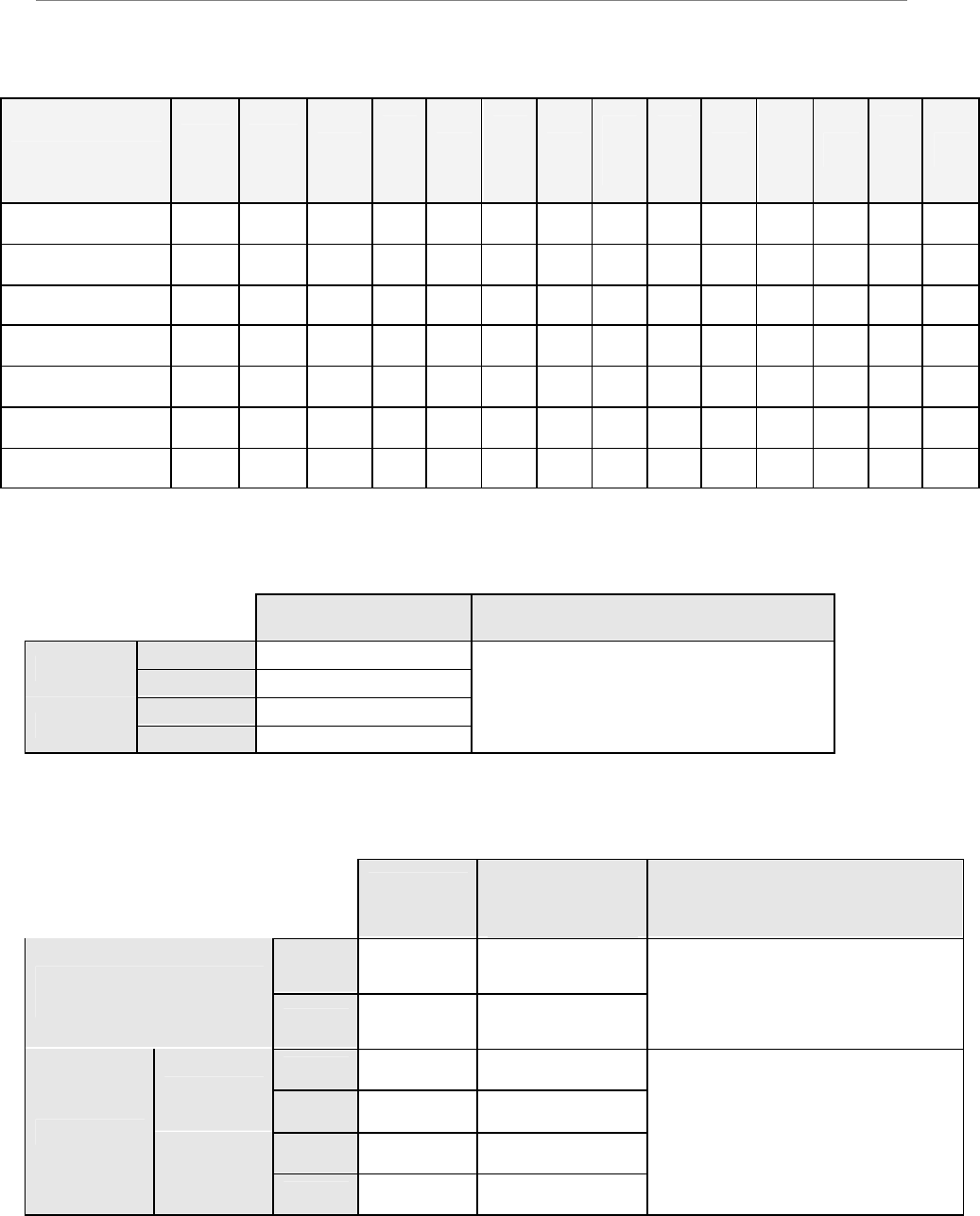

Table L2: Cable Attenuation in dB per 100 Feet

Cable Type 2 ¼?

LDF

12-50

1 5/8?

LDF 7-

50A

LMR

1700

1 ¼?

LDF

6-

50A

LMR

1200

7/8?

LDF

5-

50A

LMR

900

5/8?

LDF

4.5-

50A

½ ?

LDF

4-

50A

LMR

600

½ ?

Super

flex

FSJ

4-

50B

LMR

500

3/8?

LDF

2-

50A

LMR

400

Frequency/Size 2.350 1.980 1.670 1.550 1.200 1.090 0.870 0.865 0.630 0.590 0.520 0.500 0.440 0.405

2000 MHz 0.994 1.11 1.5 1.42 1.99 1.82 2.64 2.27 3.25 3.9 5.09 4.84 5.17 6

2400 MHz N/A 1.24 1.7 1.5 2.2 2.02 2.9 2.52 3.63 4.3 5.67 5.4 5.67 6.6

2500 MHz N/A 1.27 1.71 1.53 2.26 2.07 3 2.58 3.70 4.42 5.8 5.48 5.79 6.8

2600 MHz N/A 1.3 1.8 1.57 2.3 2.12 3.1 2.64 3.78 4.5 5.94 5.6 5.91 6.9

Weight lbs/ft 1.22 0.82 0.74 0.63 0.45 0.33 0.27 0.15 0.15 0.13 0.14 0.1 0.08 0.07

Bend Radius (inches) 24 20 13.5 15 6.5 10 3 8 5 1.5 3 1.25 3.75 1

Table L3: 2.4 GHz TTA BTA Max Power and Frequency Range Supported

Max Power Frequency Range Supported

Omni 17.5 dBm

US Sector 16 dBm

Omni 24 dBm

ETSI Sector 18 dBm

2.400 to 2.483 GHz

Table L4: 2.4 GHz TTA BTA Cable Loss and Corresponding Cable Length

Cable

Loss

Calculated

Length of RG6

Bundled Cable Engineering Notes

Min 5 dB 40 ft (12 m)

US

(Omni & Sector) Max(1)

20 dB 180 ft (55 m)

For a cable loss of more than 15 dB,

Adjacent Channel Power degradation

will occur.

At 20 dB of cable loss a minimum

ACP degradation of 3dB will occur

Min 5 dB 40 ft (12 m)

Omni Max(2)

20 dB 180 ft (55 m)

Min 5 dB 40 ft (12 m)

ETSI

Sector Max(1)

20 dB 180 ft (55 m)

For a cable loss of more than 15 dB,

Adjacent Channel Power degradation

will be dominated by RFC.

At 20 dB of cable loss RFC SNR will

be approaching 30 dB

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 169

October 23, 2003

Table L5: 3.5 GHz TTA BTA Max Power and Frequency Range Supported

Max Power Frequency Range Supported

ETSI

(Omni & Sector) 30 dBm 3.410 to 3.700 GHz

Table L6: 3.5 GHz TTA BTA Cable Loss and Corresponding Cable Length

Cable

Loss Calculated Length of

RG6 Bundled Cable Calculated Length of

RG11 Bundled Cable

Min 5 dB 35 ft (11 m) 53 ft (16 m)

ETSI

(Omni & Sector) Max(1)

30 dB 225 ft (68 m) 340 ft (104 m)

Ripwave Base Station I&C Guide Navini Networks, Inc.

170 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 171

October 23, 2003

Appendix M: Sample Bill of Materials (BoM)

1/13/2003 1:58:54 PM

BOM EXPLOSION REPORT

KIT, INSTALLATION, BTS, 2.6 Revision B

Part Number: 95-05001-00

Part

13-00034-00 : CONN, COAX, CRIMP, N STRAIGHT PLUG, EZ PIN (LMR600) . Quantity: 36

Part

13-00194-00 A CONN, COAX, CRIMP, N STRAIGHT PLUG, EZ PIN, MALE (LMR400). Quantity: 8

Part

Connectors, NType

13-00218-00 A CONN, LUG, ONE-HOLE #6. Quantity: 10

Connectors

13-00219-00 : CONN, LUG, TWO-HOLE #6. Quantity: 10

Connectors

13-00220-00 : CONN, LUG, TWO-HOLE #2. Quantity: 10

Part

18-00001-00 : CABLE, COAX, OUTDOOR RF, LMR600. Quantity: 1350

Part

18-00035-00 A WIRE, GROUND, GREEN, STRANDED, #2. Quantity: 50

Part

18-00036-00 : CABLE, COAX, OUTDOOR RF, LMR400. Quantity: 200

Cables, Coax

18-00049-00 : WIRE, STRANDED, GREEN, #6 AWG 50. Quantity: 13

Part

24-00045-00 : NUT, REG. HEX, CRES, 1/4-20UNC. Quantity: 8

Part

24-00117-00 : BUSS BAR, GROUND, TOWER, 1/4IN X 2-1/2IN X 12-1/2IN. Quantity: 1

Part

24-00118-00 : BUSS BAR, GROUND, SHELTER, 1/4IN X 4IN, DRILLED TO 5/8IN. Quantity: 1

Part

24-00119-00 : GRIP, HOISTING, PRE-LACED, FOR 1/2IN COAX CABLE. Quantity: 10

Part

24-00120-00 : HANGERS, ASSY, CUSHION, 5H, 1/2IN CORREGATED COAX. Quantity: 4

Mechanical Hardware

24-00121-00 : MOUNT, HANGER, CROSS CUSHION, KIT OF 5. Quantity: 2

Part

24-00122-00 : BLOCK, SUPPORT, MINI COAX. Quantity: 2

Part

24-00134-00 A BREAKER, OUTPUT DISTRIBUTION, 60 AMP, BTS INSTALLATION. Quantity: 1

Ripwave Base Station I&C Guide Navini Networks, Inc.

172 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Mechanical Hardware

24-00156-00 : CLAMP, PIPE TO PIPE, KIT OF 2. Quantity: 1

Mechanical Hardware

24-00170-00 : NUT, REG. HEX, CRES, #10-24. Quantity: 3

Part

24-00171-00 : WASH, STAR, #10. Quantity: 3

Part

24-00172-00 : WASH, STAR, ¼. Quantity: 16

Part

24-00250-10 : BOLT, HEX, 1/4-20 X 1.000 LG, SSPA. Quantity: 8

Mechanical Hardware

24-06156-43 : WASH, FLAT, CRES, #6 T-B-REGULAR, .156 X .438 X .040. Quantity: 16

Part

24-06250-14 : WASH, LOCK, SPLIT, CRES 1/4, Reg, .252X.487X.062. Quantity: 16

Part

32-00031-00 : ARRESTOR, LIGHTNING, RF 1.2 - 2.8GHz, N TYPE FEMALE, DC BLOCK, PSX. Quantity: 9

Part

32-00033-00 : ARRESTOR, LIGHTNING, GPS, PICKOR, DC PASS, MM50MNZ+6. Quantity: 2

Part

32-00052-00 : KIT, GROUNDING, LMR-600, 5FT X 1/2 IN, 2 HOLE LUG. Quantity: 9

Part

32-00053-00 : KIT, GROUNDING, LMR-400, 5FT X 3/8 IN, 2 HOLE LUG. Quantity: 2

Part

32-00077-00 : KIT, WEATHERPROOFING, GEL WRAP. Quantity: 1

Part

32-11004-00 : ARRESTOR, SURGE, EMP, DC BLOCK, RF COAX, In-line 2.4 GHz., PSX-ME. Quantity: 9

Part

92-00006-00 : SUBASSY, MOUNT UNIVERSAL FOR OMNI ANTENNA. Quantity: 1

Antennas

68-00006-00 : DWG, ASSY MOUNT UNIVERSAL FOR OMNI ANTENNA. Quantity: REF

Assembly Drawing, Mechanical

55-00063-00 : BASE, WELDMENT, ANTENNA MOUNT, OMNI. Quantity: 1

Part

55-00079-00 : FLANGE C, ANTENNA MOUNT, OMNI. Quantity: 1

Part

55-00080-00 : GUSSET, ANTENNA MOUNT, OMNI . Quantity: 2

Part

55-00081-00 : PLATE, BASE, ANTENNA MOUNT, OMNI. Quantity: 1

Part

24-10000-00 : NUT, PEM, BLIND .250 1/4-20 BS-0420-2. Quantity: 8

Part Type

55-00088-00 : FLANGE, CLAMP, STANDARD MOUNT, GALVANIZED. Quantity: 2

Part

24-09000-00 : STUD, 7/16 X 14 LG ALL THREAD, GALVANIZED, ANTENNA MOUNT, OMNI. Quantity: 4

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 173

October 23, 2003

Mechanical Hardware

24-09001-00 : WASHER, SQ, ALUMINUM, ANTENNA MOUNT. Quantity: 4

Mechanical Hardware

24-09002-00 : WASHER, SQ, GALVANIZED, ANTENNA MOUNT. Quantity: 4

Mechanical Hardware

24-09003-00 : FLAT WASHER 7/16 REG GALVANIZED. Quantity: 12

Mechanical Hardware

24-09005-00 : LOCK WASHER, 7/16, GALVANIZED. Quantity: 12

Mechanical Hardware

24-09004-00 : HEX NUT 7/16 GALVANIZED. Quantity: 12

Mechanical Hardware

24-00124-00 : BOLT, HEX 1/4-20 X 1.250 LG SSPA. Quantity: 8

Part Type

24-06250-14 : WASH, LOCK, SPLIT, CRES 1/4, Reg, .252X.487X.062. Quantity: 8

Part

24-06250-28 : WASH, FLAT, CRES, 1/4 T-B-REGULAR, .281 X .734 X .063. Quantity: 8

Ripwave Base Station I&C Guide Navini Networks, Inc.

174 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 175

October 23, 2003

Appendix N: Install Connectors on Cables

Reference Chapter 1, Page 8 “Regulatory Information” requirements.

The following article, written by Lou Caruso of Times Microwave Systems, appears in Volume 8

Issue 5, 2000 of Telecom Exchange.

“Among the keys to success in any wireless system are the quality and reliability of the connector

installations on the coaxial cable transmission lines. And it naturally follows that the more difficult

the connectors are to install, the lower the likelihood that they will be installed correctly thus

adversely affecting the quality and reliability of the entire system.

Traditional connectors require the pin contact to be soldered to the center conductor of the coax

cable. Unfortunately, when RF transmission lines are installed outdoors as is often the case, weather

conditions may not be conducive to using soldering equipment. Wind, rain and snow all can make

soldering difficult if not impossible. If electrical power isn’t available, gas or butane fired soldering

equipment may be the only recourse and these devices typically do not generate as much heat as

electrically powered devices. Consequently, they may not do as good of a job. The physical handling

of the cable, connector pin, butane torch and solder can also be tricky (not enough hands!),

especially if there’s only one person doing the installation.

For indoor installations, such as distributed antenna systems in buildings, the installer may be

working in cramped spaces, on a ladder and in low-light conditions. How can these issues be

overcome to ensure a reliable connector installation and proper system performance?

Simplicity is the key. The connector installation process can be simplified with the use of non-solder

connectors and the correct installation tools. We have designed non-solder connectors to work with

our LMR? low-loss flexible 50-Ohm coaxial cables. These connectors may be installed under all

field installation conditions, because they use either silver or gold plated copper-beryllium spring

finger contacts that make positive contact with the center conductor and do not require soldering.

Small cable sizes, LMR-400 (3/8”) and LMR-600 (1/2”), require a crimp-style contact attachment

ring. When the cable is larger, the LMR-900-DB (5/8”) for example, a larger clamp method of

attachment is needed. Interfaces available include 7-16DIN, N, TNC and reverse polarity TNC

connectors.

Even though using non-solder connectors is simpler, there are still certain techniques that must be

used if a proper connection is to be achieved. Additionally, you must use the proper tools to get the

job done, including stripping, prepping and deburring instruments. Poorly installed connectors are

the most common cause of voltage standing wave ratio problems. Likewise, a good connection will

achieve the best RF transmission performance with a minimum of signal loss. The following

techniques will ensure a good connection and long-term reliability.

Ripwave Base Station I&C Guide Navini Networks, Inc.

176 Part #40-00047-00 Rev F v1.0 (TTA)

October 23, 2003

The typical procedure for installing the connector on cable sizes LMR-400 and LMR-600 (also is the

same procedure on DB and FR) is:

?? Flush cut the cable squarely.

?? Slide the heat shrink boot and crimp ring onto the cable. Strip the cable-end using the ST-400-EZ

or ST-600-EZ prep/strip tool by inserting the cable into End 1 and rotating the tool. Remove any

residual dielectric material from the center conductor.

?? Insert the cable into End 2 of the tool and rotate the tool to remove the plastic jacket.

?? Deburr the center conductor using the DBT-01 deburring tool.

?? Flare the braid slightly and push the connector body onto the cable until the connector snaps into

place, then slide the crimp ring forward, creasing the braid.

?? Temporarily slide the crimp ring back, and remove the connector body from the cable to trim the

excess braid at the crease line, then remount the connector and slide the crimp ring forward until

it butts up against the connector body.

?? Position the heavy duty HX-4 crimp tool with the appropriate dies (CT-400/300 tool may be

used on LMR-400) directly behind and adjacent to the connector body, and crimp the connector.

The HX-4 crimp tool automatically releases when the crimp is complete.

?? Position the heat shrink boot as far forward on the connector body as possible, without

interfering with the coupling nut and use a heat gun to form a weather tight seal.

The procedure for installing the connector on cable sizes LMR-400-LLPL and LMR-600-LLPL is

very similar with a couple of differences:

?? Flush cut the cable squarely.

?? Slide the heat shrink boot and crimp ring onto the cable. Strip the cable-end using the ST-400-EZ

or ST-600-EZ prep/strip tool by inserting the cable into End 1 and rotating the tool. Remove any

residual dielectric material from the center conductor.

?? Insert the cable into End 2 of the tool and rotate the tool to remove the plastic jacket.

?? Deburr the center conductor using the DBT-01 deburring tool.

?? Flare the braid slightly, then put a slight taper on the front edge of the aluminum-covered

dielectric by ‘rolling’ your fingers around the stripped end. (The heat shrink boot can also be

used rather than your fingers.)

?? Rotate (turn) and push the connector body with a screwing motion (to prevent the foil from

pushing back) onto the cable until the connector snaps into place. Then slide the crimp ring

forward creasing the braid.

?? Temporarily slide the crimp ring back, and remove the connector body from the cable to trim the

excess braid at the crease line, then remount the connector and slide the crimp ring forward until

it butts up against the connector body.

?? Position the heavy duty HX-4 crimp tool with the appropriate dies (CT-400/300 tool may be

used on LMR-400-LLPL) directly behind and adjacent to the connector body, and crimp the

connector. The HX-4 crimp tool automatically releases when the crimp is complete.

?? Position the heat shrink boot as far forward on the connector body as possible, without

interfering with the coupling nut and use a heat gun to form a weather tight seal.

Navini Networks, Inc. Ripwave Base Station I&C Guide

Part #40-00047-00 Rev F v1.0 (TTA) 177

October 23, 2003

For installing the ‘EZ’ connectors on LMR-900-DB, FR and LLPL cables and larger, the process is

as follows:

?? Flush cut the cable squarely.

?? Slide the backnut and gasket onto the cable.

?? Strip the cable-end using the EZ prep/strip tool by inserting the cable into the proper end of the

tool (note that only one strip is needed).

?? Slide the gland washer on the end of the cable and over the braid (being careful not to disturb the

braid) until it rests on the end of the cable jacket.

?? Spread the braid over the gland washer.

?? Slide the collar over the foil.

?? Push the ‘spring finger’ end of the connector pin assembly into the hollow center conductor.

?? Bring up the backnut and gasket.

?? Screw the connector head onto the backnut and tighten with proper size wrenches until the

gasket is almost fully compressed.”

Table N1: Reference Chart Showing ‘EZ’ Connectors For Use with LMR, DB & FR Cables

LMR? FR

DB Interface Description Part

Number Coupling

Nut Inner

Contact Outer

Contact

400 N Male Straight

Plug EZ-400-

NMH Hex Spring